Aluminum ash ball mill

Production capacity: 0.65-615t/h

Discharge size: 0.074-0.89mm

Ball load: 1.5-338t

Application: Used in aluminum ash, metallurgy, chemical industry and other industries.

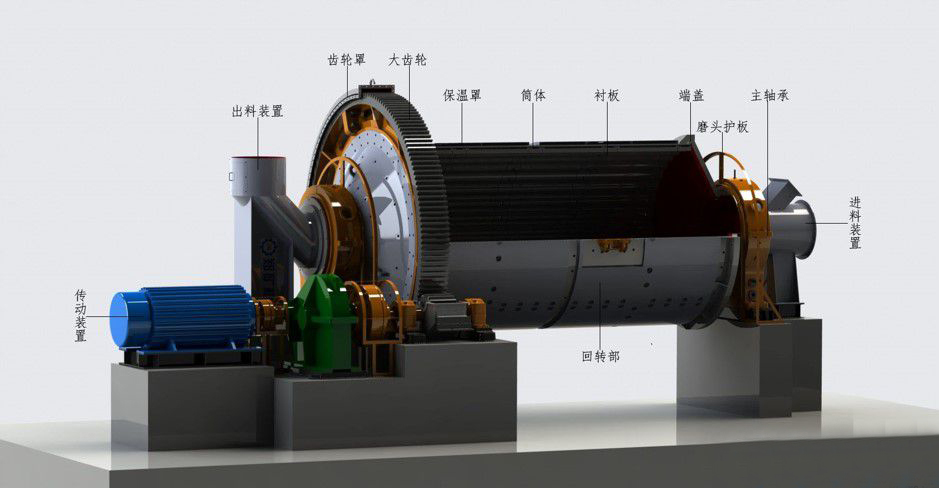

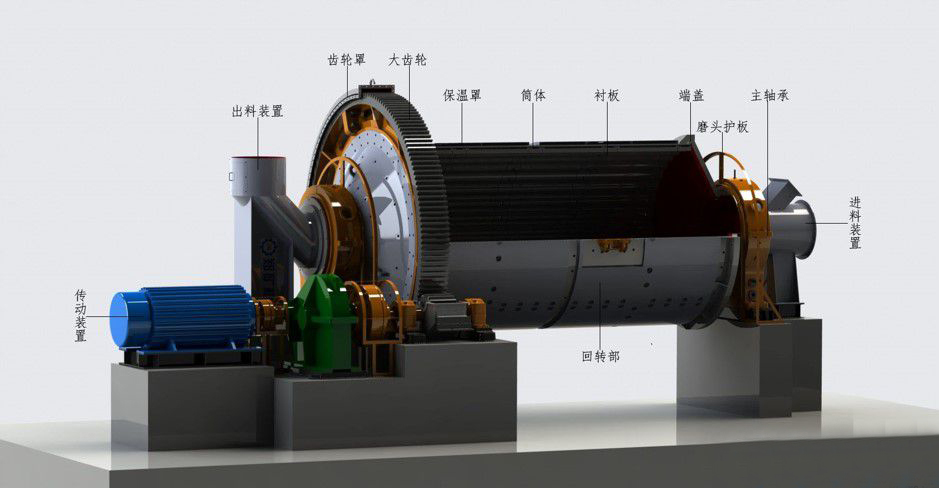

Aluminum ash ball mill product introduction

Aluminum ash ball mill is our company combined with the characteristics of aluminum ash after many years of improvement into a special beneficiation mill, the machine has a high controllability in the production of aluminum ash, and combined with a series of advantages such as energy-saving ball mill, to achieve energy saving, high efficiency and low pollution characteristics.

Outstanding advantage

1, improve the recovery rate: aluminum ash ball mill compared with the existing recovery method (now using aluminum ash separator, aluminum ash ball mill, ore washing machine), the recovery rate has been greatly improved;

2, less investment: aluminum ash ball mill outlet installed on the cylinder screen with knocking function, than the traditional method to save a linear vibrating screen, can save investment, reduce operating costs;

3, energy saving: aluminum ash ball mill operation does not need oil, coal and other precious energy, directly use the heat in hot ash treatment aluminum ash, save a lot of energy;

4, small dust: the outlet of the special ball mill is equipped with a dust collection cover, which greatly reduces dust.

Working principle

The aluminum ash ball mill adopts a horizontal cylindrical rotating device and is driven along the outer gear. The material is uniformly fed into a bin of the mill by the feeding device through the feeding hollow shaft. There are stepped lining plates or corrugated lining plates in the bin, and steel balls of different specifications are installed inside. The centrifugal force generated by the rotation of the cylinder will bring the steel balls to a certain height and then fall down, which will have a pounding and grinding effect on the material. After the material is coarse ground in the first bin, it enters the second bin through the single compartment plate, which is inlaid with a flat liner plate and contains a steel ball to further grind the material. The powder is discharged through the discharge grate to complete the grinding operation.

Technical parameter

| specification | Yield (t/h) | Speed (r/min) | Grinding body (t) | Electric machine | Reduction gear | Weight (t) |

| Model number | power | Model number | Speed ratio |

| φ1.2x4.5 | 1.7 | 30.3 | 5 | YR250M-6 | 55 | ZD30-8 | 4.481 | 13.1 |

| Φ1.5x5.7 | 4.5 | 26.34 | 11 | JR127-8 | 130 | ZD40-7 | 4 | 25 |

| φ1.83x6.4 | 8.5 | 23.9 | 18 | JR137-8 | 210 | ZD60-8 | 4.5 | 35.3 |

| Φ1.83x7 | 11 | 24.5 | 20 | JR138-8 | 245 | ZD60-8 | 4.5 | 37.2 |

| ①2.2x6.5 | 16 | 21.4 | 28 | JR138-8A | 280 | ZD70-9 | 5 | 48.5 |

| φ2.2x7.5 | 16-21 | 21.4 | 32 | JR158-8 | 380 | ZD70-9 | 5 | 53.6 |

| φ2.4x7 | 17-19 | 20.4 | 36 | JR158-8 | 380 | JD560 | 6.33 | 78 |

| φ2.4x8 | 24-26 | 20.3 | 41 | JR1510-8/Y180L-8 | 475/11 | JD630 | 6.33 | 82.3 |

| ①2.4x12 | 35-38 | 20 | 62 | YR800-8/1180/Y180L-8 | 800/11 | JD800/ZD82.5-7-1 | 6.33/99.96 | 120.3 |

| φ2.4x13 | 35-38 | 19.4 | 69 | YR800-8 | 800 | JDX800/MBY800 | 6.33 |

|

| φ2.6x 13 | 50-55 | 19.5 | 83 | YR1000-8/1180 | 1000 | JDX800/MBY800 | 4.5 |

|

| φ2.8x5+3 | 36-47.8 | 18.6 | 56 | YR500-8 | 500 | ZDH80 | 4.5 |

|

| φ2.8x10 | 40-48 | 19.7 | 70 | YR800-8/1180 | 800 | D110A | 37.5 |

|

| φ3x7+1.8 | 44 | 18 | 76 | JRQ1512-6/Y180L-6 | 780/5 | JD800/ZD82.5-8-1 | 7.1 | 125.3 |

| φ3x9 | 28-32/50-55 | 18.34 | 78 | YR1000-8/1180/Y160M-4 | 1000/11 | NZL1080/ZS110 | 8/280 | 160 |

| φ3x11 | 45-48 | 18.7 | 91 | YR800-8/1180 | 800 | ZD100A-41 | 6.43 |

|

| φ3x12 | 55-58 | 18 | 100 | YR1250-8/1430 | 1250 | JS110-A | 41.1 |

|

| φ3.2x9 | 65 | 17.6 | 88 | YR1250-8/1430 | 1250 | JS110-A | 41.28 | 189.5 |

| φ3.2x10 | 55 | 17.6 | 98 | YR1000-8/1180 | 1000 | JS110 | 41.5 |

|

| φ3.5x10 | 73 | 16.8 | 118 | YR1250-8 | 1250 | JS110-A |

| 153.7(Motor free) |

| φ3.6x7.5+2.5 | 90 | 17.3 | 125 | YRKK710-8 | 1400 | JDX900 | 7.1 | 220 |

| φ3.8x7.5 | 85 | 16.4 | 103 | YRKK710-8/Y200L2-6 | 1400/22 | NBY800/YNS620-90 | 5.6/90 | 182 |

| φ3.8x7.5 | 90 | 17 | 103 | YR710-8 | 1600 | JDX900 |

| 218(Motor free) |

| φ4.6x10+3.5 | 210 | 15 | 278 | YRKK1000-8 | 3550 | JQS3500 |

| 358(Motor free) |