Aluminum ash slag resource disposal production line

Product introduction: Aluminum ash is the ash produced in the production process of electrolytic aluminum or cast aluminum, which belongs to dangerous solid waste. Aluminum ash contains aluminum, alumina, aluminum carbide, silicon, fluoride, chloride and other components. Among them, alumina accounts for more than 70%, which has a high recycling value.

Processing capacity: 1-200,000 tons/year

Processing materials: aluminum ash, aluminum slag, aluminum scrap and other hazardous waste

Equipment configuration: rotary kiln, ball mill, dust collector and other equipment

Outstanding advantage

Aluminum ash is the ash produced in the production process of electrolytic aluminum or cast aluminum, which belongs to dangerous solid waste. Aluminum ash contains aluminum, alumina, aluminum carbide, silicon, fluoride, chloride and other components. Among them, alumina accounts for more than 70%, which has a high recycling value. Aluminum ash consists of primary aluminum ash, secondary aluminum ash, cathode carbon block, anode carbon slag, electrolytic cell impermeable material, refractory material, dust collection ash of aluminum alloy plant, aluminum processing sludge, etc.

Aluminum ash should start from the quantity, nature, composition and other potential value, the direction of use is:

1, The use of our company's aluminum ash ball mill production line can effectively extract the elemental aluminum in aluminum ash, for smelting aluminum ingot.

2, With our aluminum ash ball mill production line after lifting aluminum waste ash can be directly used for the production of special cement.

3, The use of our company's aluminum ash mixing mill and aluminum ash rotary kiln production line can produce calcium aluminate and water purification materials.

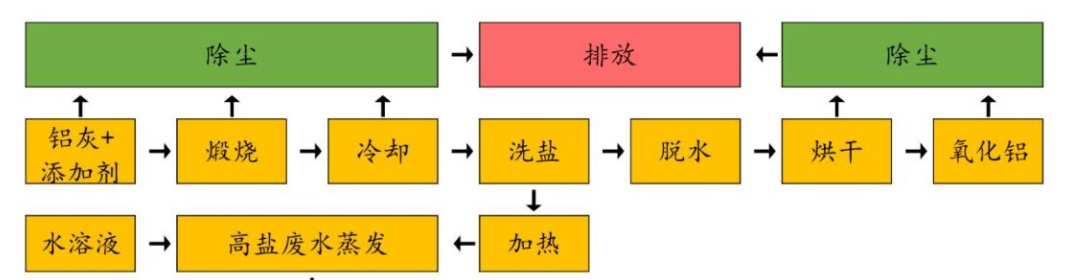

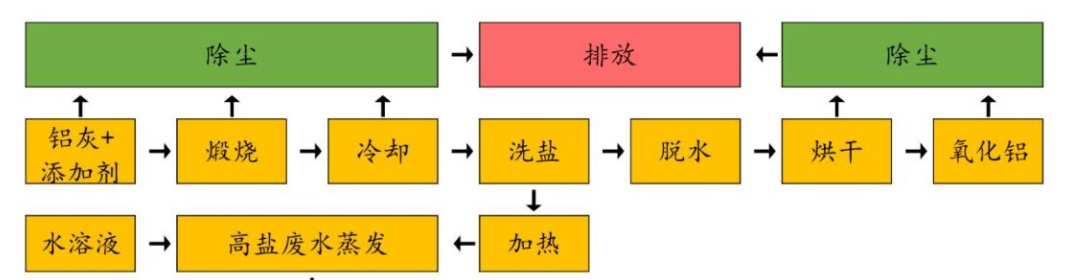

Process flow

Harmless process: through acid leaching, alkali leaching, washing and other methods, remove the nitride, fluoride, salt and other impurities in the secondary aluminum ash, and then get harmless aluminum ash for safe landfill. Recycling process: After removing toxic and harmful substances, secondary aluminum ash is processed at high temperature or cold to make different products such as steel claw protection ring, brown corundum abrasive, refining agent and water purification agent, or returned to the electrolytic cell as electrolytic aluminum raw materials.

Technical parameter

Aluminum ash is an important solid waste in aluminum industry, the composition of aluminum ash is very complex, which contains a large number of available resources, but because it also contains a certain amount of toxic elements, it is listed in the national hazardous waste list, and it is difficult to treat and utilize.

Our company after years of research and development and production of solid hazardous waste disposal production line equipment, can contain aluminum ash slag resources, harmless, and have a full set of pilot lines. The purpose of the pilot test is to smoothly transition the formula and process developed in the pilot test to industrial production, so as to ensure that the product quality of industrial production is consistent with the quality of the pilot and pilot production. The equipment (design requirements and operating principle) and process of the pilot test line of the rotary kiln of our company are consistent with industrial production, which can reflect the actual situation of industrial production, including the quality of raw materials, process control and the quality of the final product; It can provide reliable process means and data basis for further expanding the scale and realizing the large-scale production of economic scale of real industrial significance.