Bag type dust collector

Process air volume: 28800 after (m/h) 6000-201600 after (m/h), after (m/h) - 54000 after (m/h)

Application: Dust removal in industrial silicon production, dust removal in ceramic plant, dust removal in stone plant, dust removal in asphalt mixing station, dust removal in cement plant, dust removal in lime plant, dust removal in steel plant, dust removal in coal washing plant, dust removal in chemical fertilizer plant and other building materials, metallurgy, machinery, chemical and refractory industries.

Bag type dust collector product introduction

Bag type dust collector is a dry dust filter device. It is suitable for capturing fine, dry, non-fibrous dust. The filter bag is made of textile filter cloth or non-textile felt, and the dust containing gas is filtered by the filter effect of fiber fabric. When the dust containing gas enters the bag dust collector, the dust with large particles and significant ratio settles down due to the action of gravity and falls into the ash hopper. When the gas containing finer dust passes through the filter material, the dust is blocked and the gas is purified. Henan Zhengkuang Machinery Co., Ltd. provides its own design, manufacture, installation of precipitator one-stop service.

Outstanding advantage

1, All steel structure design, easy to transport and install equipment;

2, Optimize the inlet and outlet air duct design, conducive to uniform air distribution;

3, Anti-leakage design, to ensure that the bag dust collector air leakage rate is reduced;

4, High reliability design, to ensure that the bag dust collector with the host equipment long-term stable operation, maintenance workload is small;

5,Low operating costs. The optimized process parameter design is conducive to the stable operation of the bag dust collector with low resistance, reduce the energy consumption of the system, and effectively reduce the loss of the filter bag.

Working principle

Filter type dust collector refers to the equipment of gas solid separation when the dust and smoke pores pass through the filter layer, and the dust particles in the air stream are intercepted and collected by the filter layer.

The filter type dust removal device includes bag type dust collector and particle layer dust collector, the former usually uses the filter bag made of organic fiber or inorganic fiber fabric as the filter layer, and the filter layer of the latter is mostly composed of particles of different sizes, such as quartz sand, river sand, ceramic particles, slag and so on.

With the powder repeatedly attached to the outer surface of the filter bag, the powder layer continues to thicken, and the resistance value of the bag dust collector also increases. The pulse valve diaphragm gives instructions, the pulse valve is opened when the left and right flood, the compressed air in the high pressure air bag is passed, if there is no dust or small to a certain degree, the mechanical cleaning work will stop working.

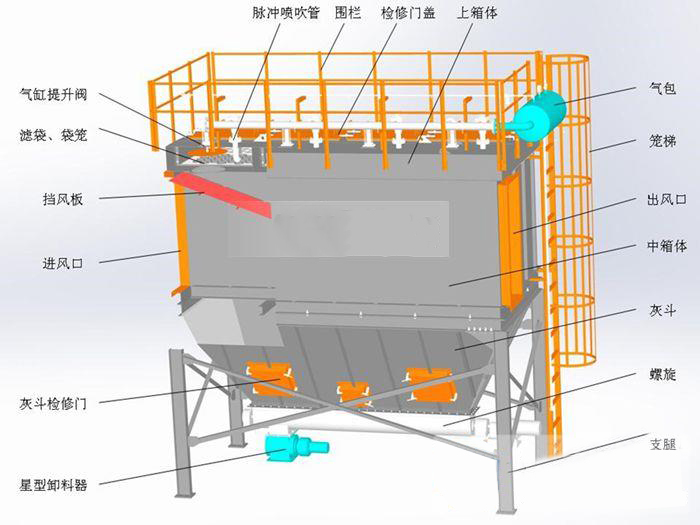

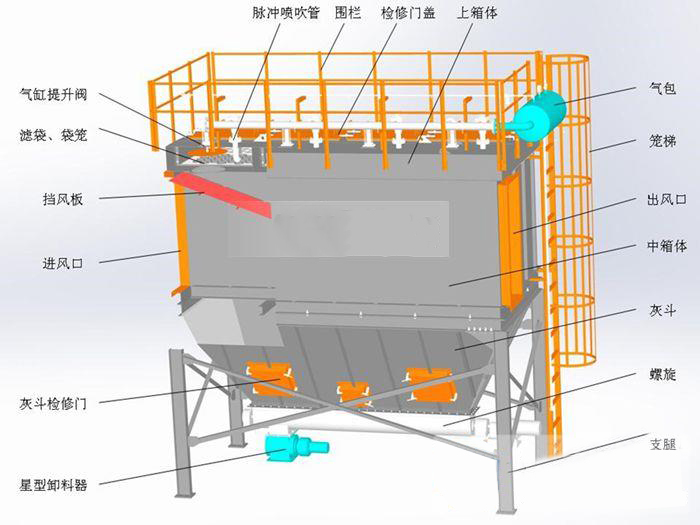

The dust collector is composed of bracket, ash hopper, middle box, upper box, filter bag, frame, blowing ash cleaning device and PLC control program. The middle box has a divided chamber structure, and the dust-containing gas is distributed in each ash hopper through the collecting pipe during operation. The coarse dust particles fall directly into the lower part of the ash bucket due to the impact of the decrease in wind speed and the action of the baffle plate of the ash bucket. The fine dust rises with the air flow and spreads between each filter bag, and the fine dust is blocked on the outer surface of the cloth bag. The clean gas passes through the cloth bag and enters the exhaust duct to discharge the body into the atmosphere with the effect of negative pressure.

Technical parameter

Main technical parameters of bag type dust collector

| Model number | Air volume (m3/h) | Filter wind speed (m/min) | Filter area (m2) | Number of chambers | Equipment Resistance (Pa) | Filter bag size (mm) | Number of filter bags (PCS) | Temperature resistance (℃) | Ash clearing square type | Equipment weight (t) | System installed capacity (kW) |

| ZL600 | 28800-

43200 | 0.8-1.2 | 600 | 3 | 1500 | φ130x5150 | 288 | <230℃ | Off-line pulse cleaning | 16.5 | 100 |

| ZL800 | 38400-

57600 | 0.8-1.2 | 800 | 4 | 1500 | φ130x5150 | 384 | <230℃ | Off-line pulse cleaning | 23.6 | 140 |

| ZL1000 | 48000-

72000 | 0.8-1.2 | 1000 | 5 | 1500 | φ130x5150 | 480 | <230℃ | Off-line pulse cleaning | 27.8 | 185 |

| ZL1600 | 76800-

115200 | 0.8-1.2 | 1600 | 8 | 1500 | φ130x5150 | 768 | <230℃ | Off-line pulse cleaning | 45.6 | 260 |

| ZL2400 | 115200-

172800 | 0.8-1.2 | 2400 | 12 | 1500 | φ130x5150 | 1152 | <230℃ | Line pulse cleaning | 76.5 | 380 |

| ZL2800 | 134400-

201600 | 0.8-1.2 | 2800 | 14 | 1500 | φ130x5150 | 1344 | <230℃ | Off-line pulse cleaning | 87.8 | 430 |

| Main technical parameters of pulse dust collector |

| Model number | Air volume (m3/h) | Filter wind speed (m/min) | Filter area (m2) | Equipment Resistance (Pa) | Filter bag size (mm) | Number of filter bags (PCS) | Temperature resistance (℃) | Cleaning method | Equipment weight (t) |

| ZM100 | 6000-7000 | 1-1.2 | 100 | 1200 | φ130 | 100 |

<230℃ | Pulse cleaning | 3.6 |

| ZM120 | 7200-8640 | 1-1.2 | 120 | 1200 | φ130 | 100 |

<230℃ | Pulse cleaning | 4.3 |

| ZM150 | 9000-10800 | 1-1.2 | 150 | 1200 | φ130 | 100 |

<230℃ | Pulse cleaning | 5.7 |

| ZM200 | 12000-

14400 | 1-1.2 | 200 | 1200 | φ130 | 200 |

<230℃ | Pulse cleaning | 7.3 |

| ZM250 | 15000-

18000 | 1-1.2 | 250 | 1200 | φ130 | 200 |

<230℃ | Pulse cleaning | 8.8 |

| ZM300 | 18000-

36000 | 1-1.5 | 300 | 1200 | Φ130 | 200 |

<230℃ | Pulse cleaning | 11.2 |

| ZM350 | 21000-

42000 | 1-1.5 | 350 | 1200 | φ130 | 200 |

<230℃ | Pulse cleaning | 13.3 |

| ZM400 | 24000-

48000 | 1-1.5 | 400 | 1200 | Φ130 | 200 |

<230℃ | Pulse cleaning | 15.5 |

| ZM450 | 27000-

54000 | 1-1.5 | 450 | 1200 | φ130 | 200 |

<230℃ | Pulse cleaning | 18.9 |