Ball mill

Our company is an environmental protection machinery manufacturer with many years of history, specializing in the production of ball mill equipment, The products are grid type ball mill, ceramic ball mill, air sweep mill, belt screen ball mill, raw material mill, cement ball mill, dry ball mill, wet ball mill, bearing transmission ball mill, mineral processing ball mill, intermittent ball mill, continuous ball mill, steel slag ball mill, experimental small ball mill, etc., can be selected and customized according to demand.

Specification Model: φ305×350-φ4.2x13

Applicable materials: steel slag, lime, bauxite, bluestone, kaolin, lithium ore (spodumene, lepomica), calcite, magnesite, quartz, water slag, slag, fly ash, glass, barite, potassium feldspar, alumina, granite, clinker, bauxite, limestone, aluminum ash, aluminum slag, etc.

Ball mill product introduction

1. The ball mill has strong adaptability to fluctuations in physical properties of materials (such as particle size, moisture, hardness, etc.);

2, less metal consumption per unit product, compact structure, stable operation, easy operation and maintenance;

3, the lining board is cast of high-quality wear-resistant material, wear resistance, long service life, large production capacity, large crushing ratio, can adapt to different conditions of operation;

4, fine product fineness and uniform particle size, particle grading is easy to adjust, high product pass rate, good sealing, small dust pollution, high grinding efficiency, low energy consumption.

Working principle

The material enters the cylinder body through the feeding part and the feeding part. The grinding medium (steel ball/ceramic ball) in the cylinder body will produce centrifugal force with the material as the cylinder rotates. When the medium is raised to a certain height, it will be thrown down according to the action of gravity, and the material will be crushed under the impact of the grinding medium on the material. The crushed material will be discharged from the machine through the discharge port by the thrust of the feeding and flushing water, thus completing the entire grinding process.

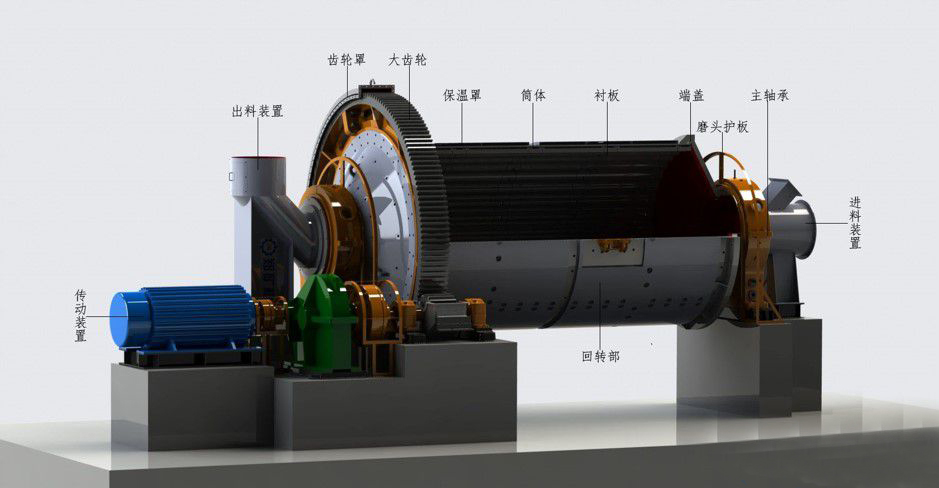

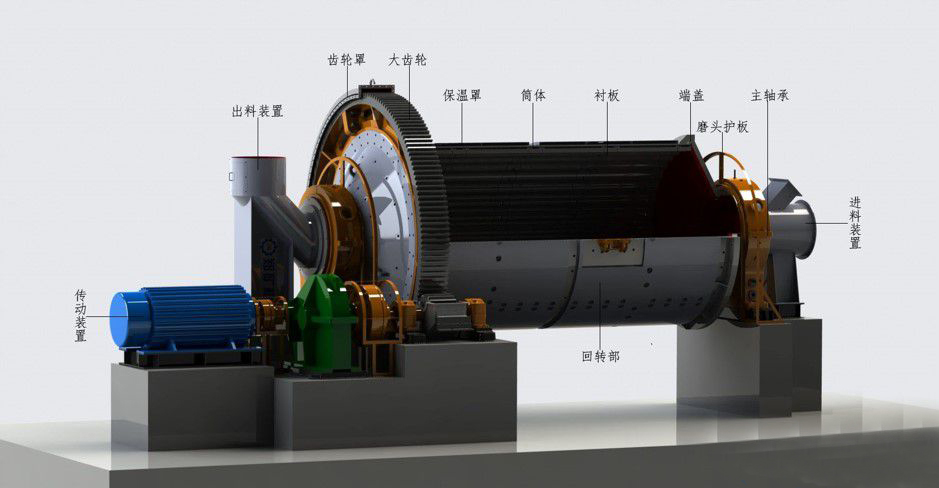

The ball mill is composed of feeding part, discharging part, rotating part, transmission part (reducer, small transmission gear, motor, electric control) and other main parts. The hollow shaft is made of steel casting, the inner lining can be disassembled, the rotary gear is made of casting hobbing, and the cylinder body is inlaid with wear-resistant lining plate, which has good wear resistance. The machine runs smoothly and works reliably.

Technical parameter

Our ball mill types, models complete, can be customized according to customer needs. The following table shows some parameters:

| Specification and model | Feed size (mm) | Discharge size (mm) | Yield (t/h) | Motor power (KW) | Weight (t) |

| φ750X750 | ≤20 | 0.074-0.3 | 0.18-0.5 | 15 | 2.774 |

| ①900X1200 | ≤40 | 0.074-0.6 | 0.2 | 5.5 | 4.8 |

| φ900X2100 | 0-15 | 0.074-0.89 | 0.69-1.30 | 15 | 5.4 |

| φ900X3000 | ≤20 | 0.074-0.89 | 1.1-3.5 | 22 | 6.8 |

| φ1200X1200 | 25 | 0.075-0.89 | 0.3-2.5 | 18.5 | 8.8 |

| Φ1200X2400 | 0-20 | 0.075-0.3 | 0.4-5.8 | 45 | 12 |

| φ1200X3000 | ≤25 | 0.074-0.6 | 0.6-7 | 37 | 13.7 |

| φ1200X4500 | ≤25 | 0.074-0.4 | 0.7-8 | 45 | 14.2 |

| Φ1500X1500 | ≤25 | 0.074-0.4 | 1.5-7 | 45 | 13.4 |

| Φ1500X3000 | ≤25 | 0.074-0.4 | 3-11 | 75 | 17.6 |

| φ1500X4500 | ≤25 | 0.074-0.4 | 4-10 | 110 | 21.2 |

| Φ1500X 5700 | ≤25 | 0.074-0.6 | 4-13 | 135 | 25.5 |

| φ1830X3000 | ≤25 | 0.074-0.4 | 4-10 | 130 | 29 |

| φ1830X4500 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

| Φ1830X5400 | ≤25 | 0.074-0.4 | 5-7 | 210 | 33 |

| Φ1830x6400 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 35 |

| φ1830X7000 | ≤25 | 0.074-0.6 | 6-22 | 210 | 36.5 |

| φ2100X2100 | ≤25 | 0.074-0.6 | 6-33 | 180 | 39 |

| Φ2100X3600 | ≤25 | 0.074-0.4 | 7.6-28 | 210 | 47 |

| φ2100X4500 | ≤25 | 0.074-0.4 | 8-43 | 245 | 46 |

| φ2400X3000 | ≤25 | 0.074-0.8 | 7-90 | 240 | 65 |

| φ2700X2100 | ≤25 | 0.074-0.8 | 9-78 | 240 | 65.5 |

| φ2700X3600 | ≤25 | 0.074-0.8 | 12-2025 | 380 | 86 |

| φ2700X4000 | ≤25 | 0.074-0.8 | 12-2040 | 380 | 92 |

| φ2700X4500 | ≤25 | 0.074-0.8 | 12-2045 | 430 | 100 |

| Φ3200X4500 | ≤25 | 0.074-0.8 | According to the process conditions | 600 | 126 |

| φ3600X4500 | ≤25 | 0.074-0.8 | According to the process conditions | 850 | 160 |

| φ3600X6000 | ≤25 | 0.074-0.8 | According to the process conditions | 1250 | 175 |