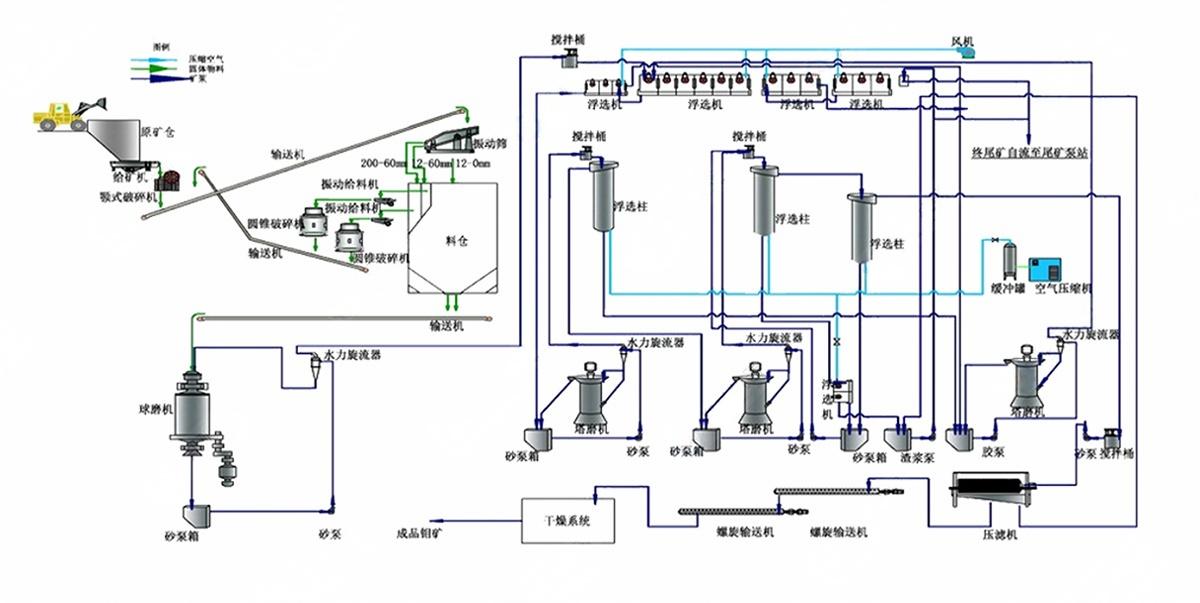

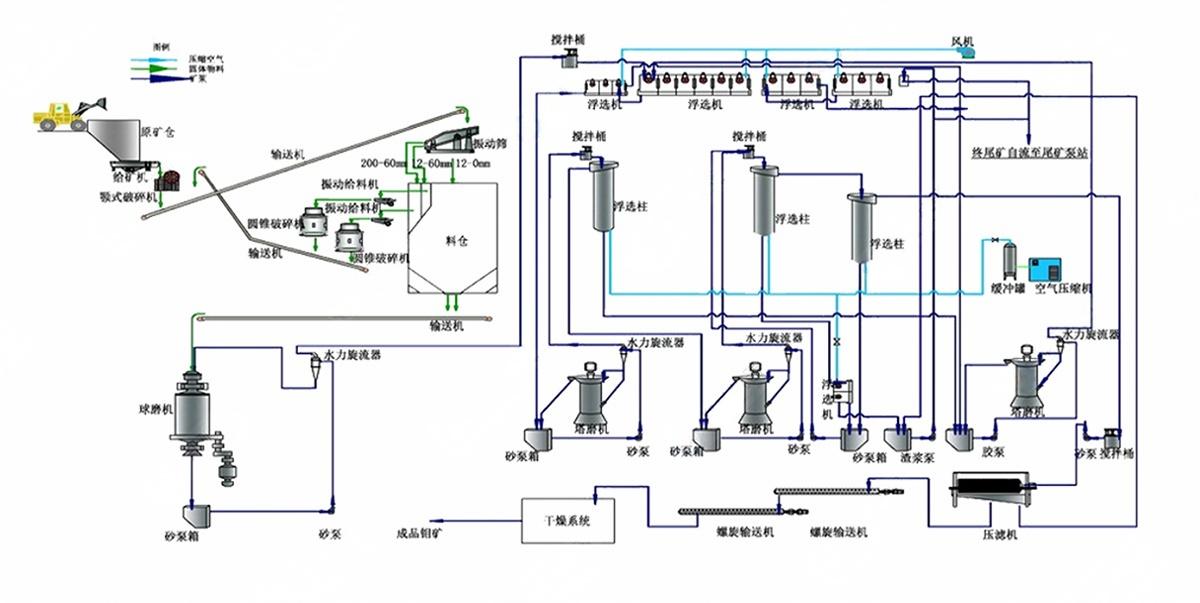

Beneficiation production line

Our company has been committed to providing customers with more professional overall mineral processing services, from mineral processing consulting, mineral processing test to process design, equipment production, and then to the entire line of equipment installation and commissioning, to achieve standards and achieve production, complete metal, non-metal mineral processing projects. Our company constantly improve and optimize their own services to form their own set of service system.

Capacity: 1-300,000 tons/year

Main equipment: jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener, dryer, feeder, elevator and conveyor

Scope of services: Provide the overall solution and equipment of mineral processing line

Outstanding advantage

1, with high efficiency, low energy consumption, high output, economic and reasonable advantages.

2, the process is simple, low cost of mineral processing equipment, easy to operate.

3, to provide customers with more professional overall mineral processing services, from mineral processing consulting, mineral processing test to process design, equipment production, and then to the entire line of equipment installation and commissioning, to achieve standards and achieve production, complete metal, non-metal mineral processing projects.

Process flow

The ore is first sent to the jaw crusher for initial crushing, and then to the ball mill for fine breaking and grinding to the right size. The ore powder discharged from the ball mill is sent to the next process: screening. Due to different specific gravity and sedimentation speed, spiral classifier can clean the grouped ore mixture, the clean grouped ore mixture is sent to the magnetic separator, due to different magnetic coefficient, under the action of magnetic and mechanical forces, the magnetic material will be separated from the mixture, and then the mixture is sent to the flotation machine, according to the characteristics of different ores, We add different additives to the mix to separate the ore we want to get out of the mix. After the separation of the mixed material, the ore we get always contains a lot of water, we need to concentrate with the thickener and then dry with the dryer, and then we can get dry ore.

Technical parameter

| Device name | Technical parameter | Custom model |

| Vibratory rod feeder | Maximum ore feeding capacity: 600t/h; Maximum feeding size: 750mm Motor power 22kw tank body: 1600×6100mm | VF561-2V |

| Jaw crusher | Crushing capacity ≥240t/h; Feeding port size: 1100×850mm; Motor power 160kw; Feed size: 750mm Discharge size: ≤130mm | C110 |

| Cone crusher | Crushing capacity ≥240t/h Maximum feed size: 140mm maximum discharge size ≤25mm Motor power 200kw(recommended value)

| HP300 |

| Circular vibrating screen | The screen surface area is 21.9m², the upper screen is 25×25mm, the lower screen is 12×24mm, and the screen is eight-shaped. Alloy rubber screen, block screen surface. Installation Angle 18°, motor Y225S-4,2×37kw | 2YKR-3073 |

| Overflow ball mill | Cylinder size (diameter × length)3600 MM×6000MM Edge drive, left-hand rotation, main motor model TM1250-40/3250 Motor power 1250kw | MQY3660 |

| Hydrocyclone group | For the first stage of grinding grading, the grading feed -200 mesh accounts for 25% of the grading product particle size -0.2mm mesh accounts for 61%. Ore density 3.8t/m3 | FX500-GXx6 |

| Feeding pressure: 0.1MPa. Overflow diameter: 160mm Settling diameter: 80, 90, 100mm |

| Spiral classifier | Motor power: 5.5kw, with automatic lifting device | FC-10 |

| Flotation machine | Effective volume: 24m3 Tank size: 3.1m×3.1m×2.9m Motor power 55kw | XCF II-24 with suction tube |

| Center drive high efficiency thickener | Dry ore handling capacity: 550t/d, feed size: 0.043mm, | NXZ-16 |

| Pulp concentration: 25%, inner diameter of thickening pool: φ16m, settling area: 200m2, hydraulic automatic rake, motor power: 5.5kW |

| Ceramic vacuum filter | Filter area 18m², equipped with a full set of devices, can use ordinary water cleaning | PD18-C |