Biscuit production line

Biscuits are a kind of food that is very popular among consumers. According to different recipes and manufacturing processes, they can be divided into crispy biscuits and tough biscuits. A suitable biscuit production line can be designed based on the actual situation of the customer's factory. These units have been elaborately designed to meet various production needs of customers. No matter what your needs are, we can provide reliable and high-quality solutions.

1. Crispy biscuit production line

2. Resilient biscuit production line

3. Multi-functional biscuit production line

Crispy biscuits are loved by many consumers because of their soft and crispy texture. We can provide fully automatic soft biscuit production lines. We understand your strict requirements for safety and hygiene, so we strictly manufacture food machinery in accordance with GMP standards. What we describe below are only common configurations. We are an experienced food machinery manufacturer and can provide different solutions for each project.

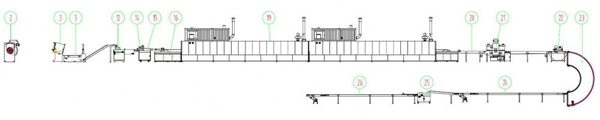

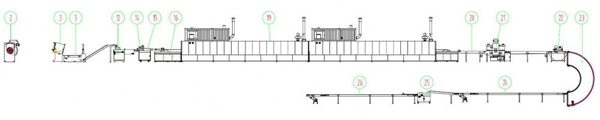

The production line equipment for crispy biscuits consists of machines

1. Horizontal dough mixer \ n2. Feeder \ n3. Dough conveyor \ n4. Roller printer \ n5. 6. Spreader \ n7. Furnace feeder \ n8. Mesh belt drive machine \ n9. Hot air convection circulation oven 10. Unloading machine \ n11. Oil injection machine \ n12. Vibrating spreader \ n13. Turning machine Cooling conveyor 14. Star wheel cake arranging machine 15. Cake picking conveyor

The hard biscuits produced by the tough biscuit production line have the characteristics of low calories, low fat and low sugar, and thus are very popular among consumers. Generally speaking, the recipes for different types of biscuits vary, so the required equipment parameters are not the same. We can provide different hard biscuit production lines based on customers' demands, featuring varying production efficiencies and configurations. The production efficiency can reach up to 1250kg/h. In addition to the biscuit production line, we can also provide molds according to your needs, so you can produce various types of biscuits.

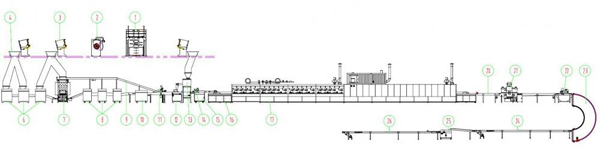

Machine configuration:

1. Vertical dough mixer \ n2. Feeder \ n3. Dough conveyor \ n4. 5. Laminating machine \ n6. Dough rolling machine \ n7. Leftover material recovery machine \ n8. Rolling and cutting machine 9. Separator \ n10. Spreader \ n11. Furnace feeder \ n12. Mesh Belt drive Oven 13. Oven machine 14. Oil sprayer 15. Vibrating spater 16. 17. Turning machine \ n18. Cooling conveyor \ n19. Star wheel cake arranging machine Cake picking conveyor 20. Packaging machine

The multi-functional biscuit production line can produce both tough and crispy biscuits. It is an integrated multi-functional production line. Generally speaking, the recipes for different types of biscuits vary, so the required equipment parameters are not the same. We can provide different biscuit production lines according to customers' demands, with different production efficiencies and configurations. The highest production efficiency can reach 1500kg/h. In addition to the biscuit production line, we can also provide molds according to your needs, so you can produce various types of biscuits.

Machine configuration:

1. Vertical dough mixer \ n2. Horizontal dough mixer \ n3. Feeder \ n4. Dough conveyor \ n5. 6. Laminating machine \ n7. Dough rolling Machine \ n8. Waste material recovery machine \ n9. Roller cutting machine Roller printing machine 10. Separator 11. Spreader 12. Furnace feeding machine 13. 14. Mesh belt drive machine \ n15. Oven \ n16. Oven machine \ n17. Oil sprayer Vibrating spreader 18. Turning machine 19. Cooling conveyor 20. Star wheel cake arranging machine 21. Cake picking conveyor 22. Packaging machine 23. Cake picking conveyor

Advantage

1.It can work around the clock

2. Since the entire production line is automated

3. The molds can be easily replaced, thus enabling the production of cookies in various shapes

4. Molds can be customized according to customers' demands

Introduction to Components

Dough mixer: An essential equipment for producing all kinds of biscuits and bread. The dough after stirring has better elasticity and softness. The stirring volume can be customized according to the customer's requirements.

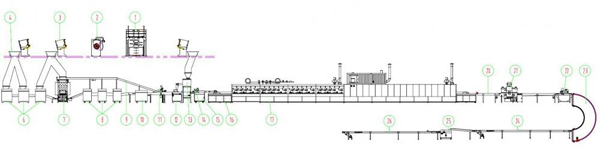

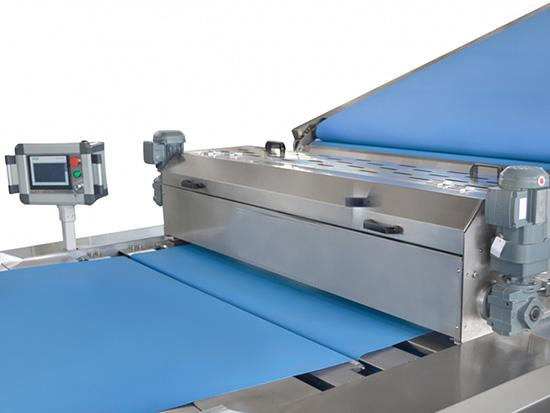

The materials of the rolls and trough rolls are made of alloy steel, which is of high hardness and will not deform. The thickness, speed and other data of the surface skin are displayed in real time on the monitor, which is convenient for the operator to adjust as needed. The conveyor belt is designed with an automatic tensioning and automatic deviation adjustment device, so the conveyor belt will not deviate

We can provide various types of ovens such as heat-sealing circulation ovens, direct-fired ovens, and infrared electric ovens to suit different types of cookies. The oven adopts a modular design, and the number of modules depends on the output of the production line.

Fuel injector

The baked cookies are treated with oil spraying to improve their color and aroma, and enhance their taste. The liquid oil is atomized at high speed and adheres finely and evenly to the products. After the product is sprayed with oil, it undergoes oil filtration to recover the excess oil for recycling and reuse. The water storage tank has heating and insulation functions. It uses an indirect heating method of electric heating water, and the temperature can be adjusted freely. The machine is made of 304 stainless steel, which is clean and hygienic.

Salt and sugar spater: It is used to evenly sprinkle a layer of salt, sugar, sesame seeds, nut slices and other seasonings on the surface of the cookie to improve the taste of the cookies

Cake arranging machine

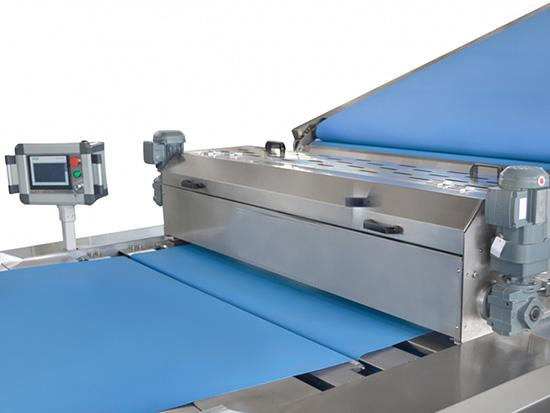

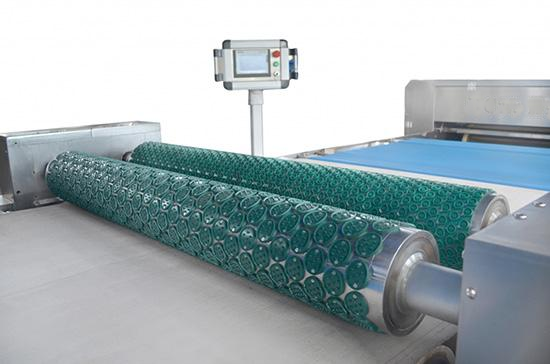

Roller printing machine

Oven feeding machine: Product function: It is used to transport the formed biscuits to the oven, and has the function of recovering the remaining materials such as sugar, salt and sesame, as well as eliminating the poorly formed waste biscuit blanks from the production line

Laminating machine

Press the dough into sheets, sprinkle flour and stack them to give the produced cookies a sense of layering. The thickness and speed of the dough sheet can be displayed in real time on the monitor, which is convenient for the operator to adjust the number of layers of the dough sheet. The width of the dough sheet can be adjusted freely.

Rolling seat

Roll the dough finely to the required thickness, and at the same time make the texture of the dough sheet more uniform and the toughness better. The roll material is made of alloy steel, which is of high hardness, does not deform, is wear-resistant and of excellent quality. The thickness, speed and other data of the dough are displayed in real time on the monitor, which is convenient for the operator to adjust as needed. The conveyor belt is designed with an automatic tensioning and automatic deviation adjustment device, ensuring that the conveyor belt does not deviate.

Forming machine

It is used for the shaping of different styles of biscuits and can simultaneously complete printing, shaping, demolding and other tasks. The feeding speed and shaping speed can be freely adjusted. The distance between the roller printing mold and the rubber roller, speed and other data are displayed in real time on the monitor, which is convenient for the operator to adjust as needed. The conveyor belt is designed with an automatic tensioning and automatic deviation adjustment device, so the conveyor belt will not deviate

Oven

It is used for baking cookies, bread, cakes and other products. According to the different needs of customers, we can provide various types of ovens such as infrared ovens, electric ovens and gas ovens. The power, length and width of the oven are all customized according to the actual needs of the customers.

Conveying equipment