Candy and biscuit equipment Product introduction

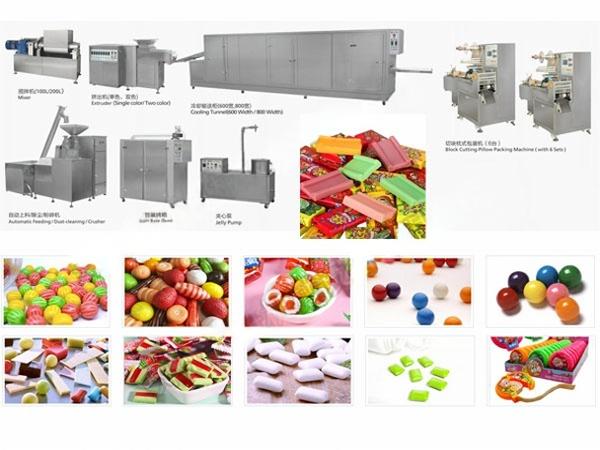

Candy production line equipment

The large-scale candy production line equipment can produce soft candies, hard candies, lollipops, filled candies, special-shaped candies, toffee and chocolate candies. This production line is a pouring equipment for hard candies and soft candies, integrating mechanics, electricity and pneumatics. It adopts servo control, has a compact structure and a high degree of automation.

Gummy candy production line

Gummy candy production line

Jelly production line equipment technology, soluble sugar, filtration, boil sugar, additives (optional), casting molding, cooling, take off the film -- - chamber - packaging

Gummy candy production line

The fully automatic PLC-controlled gel soft candy production line equipment can meet the demands for various shapes and colors of gel soft candies. It is a continuous production equipment for colloidal candies. It can produce single-color and double-color sugar. Gel gummies of various shapes and colors can also be produced by changing molds or pouring heads. The quantitative filling and mixing of materials are completed online.

Hard candy production line equipment is divided into casting hard candy production lines, stamping hard candy production lines, and extrusion hard candy production lines. It includes cream-flavored filled hard candy production equipment, casting fruit-flavored gel hard candy processing machinery, stamping refreshing hard candy production machinery and other candy production line equipment

Casting hard candy production line

The hard candy casting production line is a continuous vacuum film hard candy production line. This equipment integrates mechanics, electricity and control systems. The continuous vacuum film casting production line can produce crystal sugar, double-color sugar, double-layer double-flavor sugar, sandwich sugar, and also produce spiral-shaped spray-flower candies and other colorful and multi-flavor candies.

The process flow of the hard sugar casting production line: sugar dissolving - conveying, filtering, temporary storage, quantitative conveying of syrup - preheating film vacuum boiling, unloading, online mixing of sugar paste - content - casting - cooling - demolding - conveying - packaging - finished product

Fully automatic hard candy die stamping production line

The fully automatic hard candy die production line can produce various solid hard candies, sandwich hard candies, irregular-shaped hard candies, colored hard candies and other kinds of hard candies

The process flow of the fully automatic hard sugar die stamping production line

Sugar dissolving - storage tank - Vacuum boiling pot - cooling table - Conveyor - Insulated rolling bed - Pulling machine - Candy forming machine - cooling screen - packaging machine

Lollipop die production line

The lollipop die production line can produce lollipops of different shapes by changing molds, with a production capacity of 50-1200kg/h. If your factory needs to produce lollipops of different shapes in large quantities. The lollipop die production line adopts an electrically heated boiling pot, and the heating time and temperature are controlled by PLC.

The processing flow of the automatic lollipop die stamping production line

Sugar dissolving pot - Sugar storage tank - Vacuum continuous sugar boiling pot - cooling table - Heat preservation roller bed - Homogenizing machine - Die forming machine - shaking head distributor - Cold cabinet - packaging machine

Fully automatic lollipop casting production line

The fully automatic PLC-controlled vacuum film continuous sugar boiling and candy casting forming production line is a production equipment for casting candy. This machine integrates mechanical, electrical and pneumatic control, with a reasonable and compact structure. It can produce single-color, double-flavor and double-color spray-painted, double-flavor and double-color double-layer, triple-flavor and triple-color spray-painted, four-color and four-flavor, as well as crystal sugar, filled sugar, striped sugar, etc.

The process flow of the lollipop casting production line

Automatic weighing supporting system - Sugar dissolving - storage tank - Vacuum film boiling machine - servo casting machine - cooling tunnel - demolding - conveying - packaging - finished product

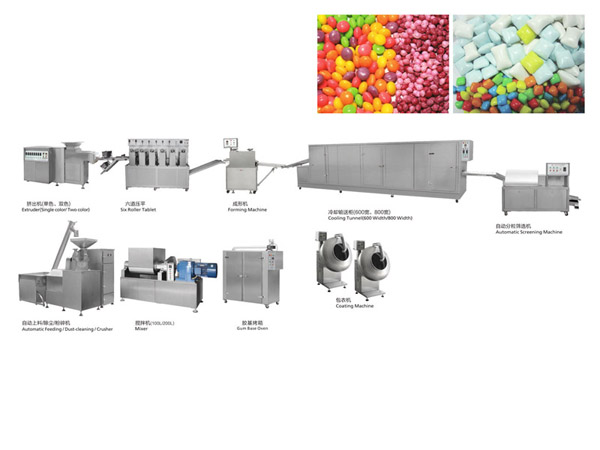

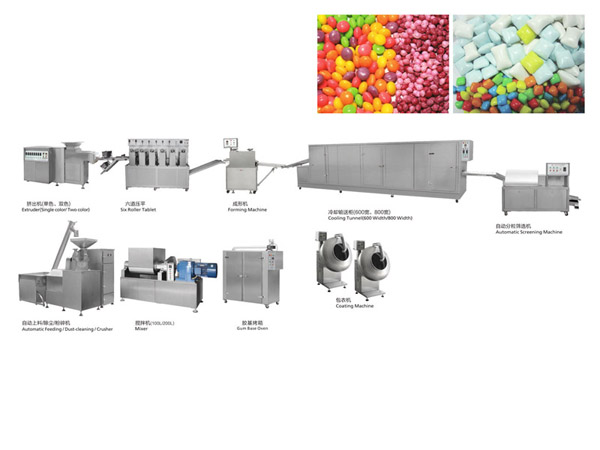

Chewing gum production line

Xylitol chewing gum production line

The main equipment for xylitol chewing gum includes: automatic feeding machine, mixer, extruder, six-pass flattening machine, forming machine, cooling and conveying cabinet, automatic granulation and screening machine, coating machine, gum base oven, etc

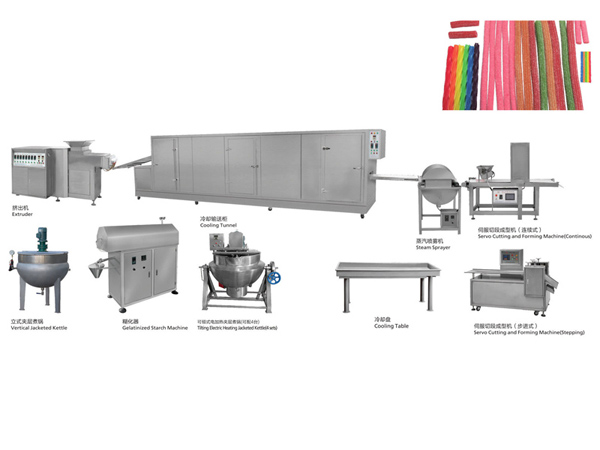

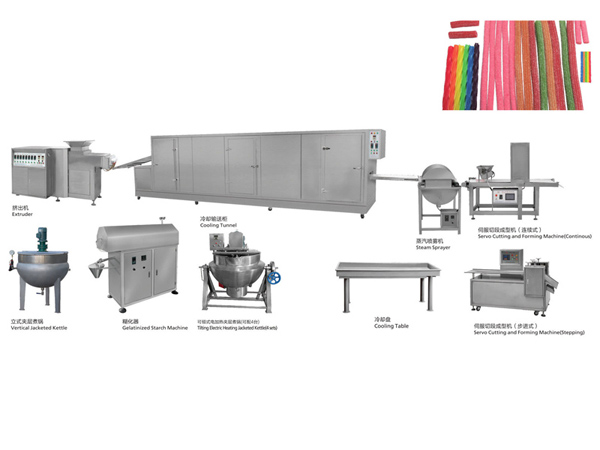

Starch gummy candy production line

Starch gummy candy production line

The main equipment of the starch gummy candy production line includes: vertical double-layer boiling pot, gelatinizer, tilting electric heating layering pot (4 units available), extruder, cooling conveying cabinet, steam sprayer, servo cutting and forming machine (continuous type), servo cutting and forming machine (step type), and cooling tray

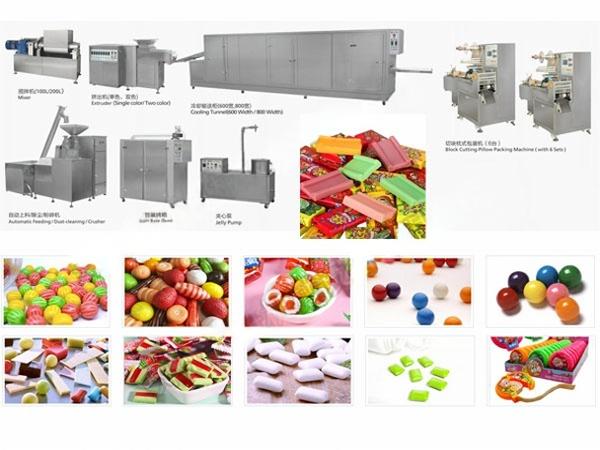

Bubble gum production line

Bubble gum production line

The main equipment of the bubble gum production line includes: automatic feeding machine, mixer, extruder, interlocking pump, forming machine, cooling and conveying cabinet, square sauce forming machine, coating machine, gum base oven, etc

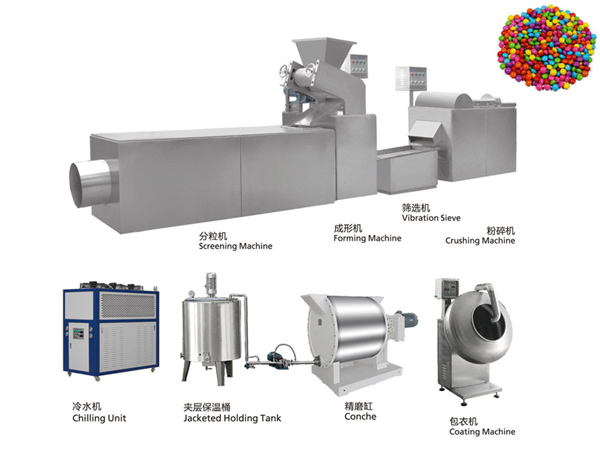

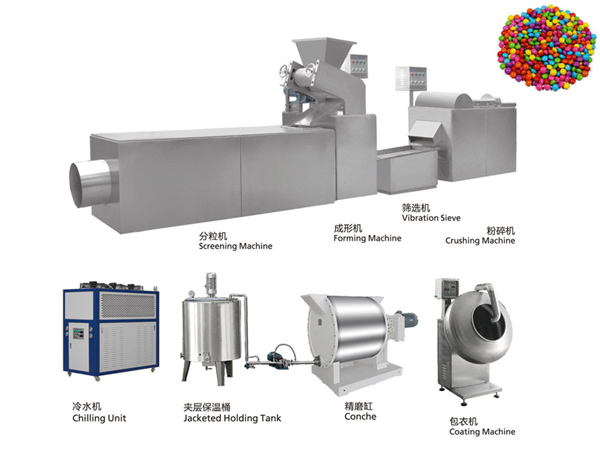

Chocolate bean production line

Chocolate bean production line

The main equipment of the chocolate bean production line includes: pelletizer, forming machine, screening machine, crusher, coating machine, fine grinding cylinder, interlayer insulation bucket, cooler, etc.

Toffee processing equipment

Toffee processing equipment

The processing flow of the toffee casting production line

Sugar dissolving pot - Sugar storage tank - Toffee boiling pot - pouring machine - cooling tunnel

The process flow of toffee production line

Sugar dissolving (electric heating sugar boiling pot) - Storage tank - Vacuum gas-filled stirring milk candy sugar boiling machine (mixer) - cooling table - Slurry conveying machine - insulated rolling bed - drawing machine - conveyor belt - candy forming machine - cooling screen - packaging machine

Popping bead production line

Popping bead production line

We provide customers with automatic popping bead production line equipment, AGAR crystal ball production line equipment, konjac crystal ball production line equipment, and horseshoe popping bead production line

The burst bead production line adopts PLC programs and touch screens, which are easy to operate and control the size of the burst bead crystal ball heads. Series SUS304 stainless steel, supporting customization, workshop planning and installation by engineers in the factory.

Chocolate production line

Chocolate forming production line

The main equipment of the chocolate forming production line: melting chocolate - filtration - adding additives (optional) - pouring forming - demolding - packaging

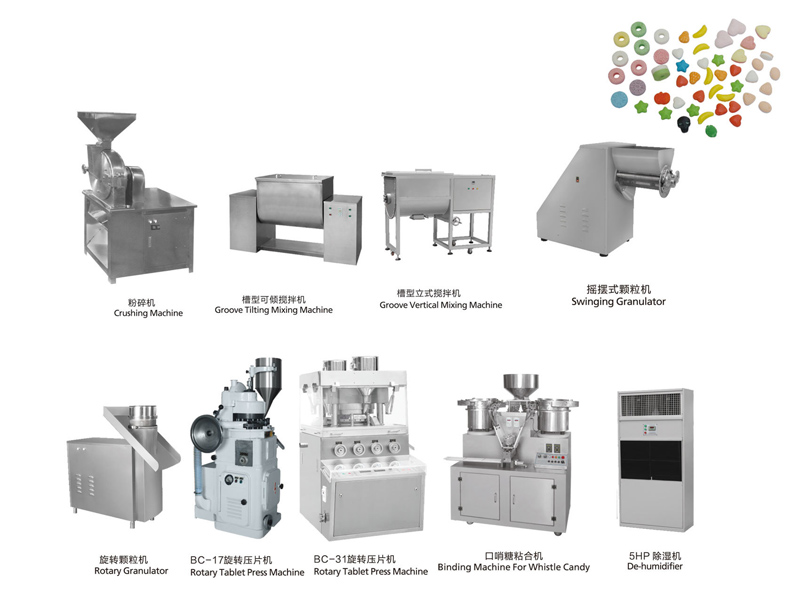

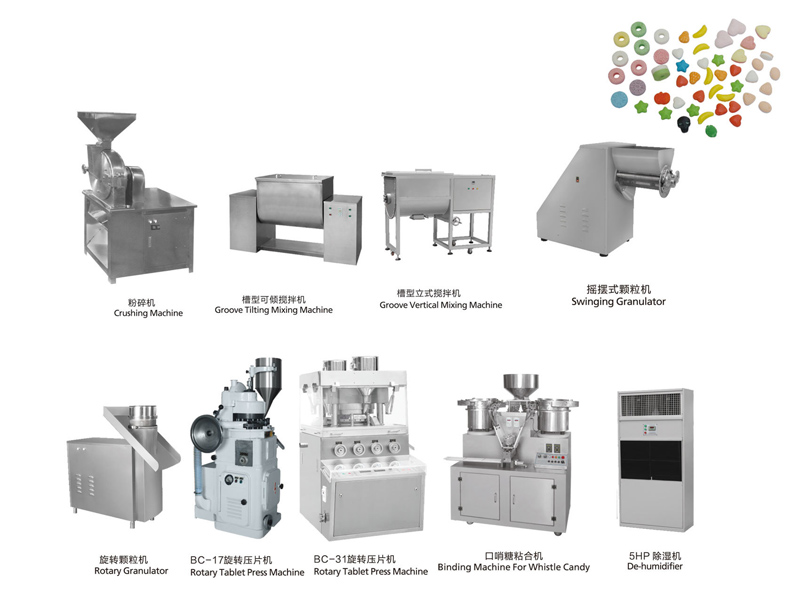

Tablet sugar production line

Tablet sugar production line

The main equipment of the tablet sugar production line includes: crusher, trough-type tilting mixer, trough-type vertical mixer, swing granulator, dehumidifier, whistling sugar bonding machine, 31 rotary tablet press, 17 rotary tablet press, and rotary granulator

Small candy machine with PLC

The small candy pouring machine with plc can make various shaped candies such as soft candies, hard candies, lollipops, milk candies and toffee candies

Semi-automatic candy machine

Semi-automatic candy machine, with automatic pouring and manual candy placing and taking molds, can make various shapes of soft candies, hard candies, lollipops, milk candies and other candies