Ceramic ball mill

The company's ceramic ball mill cylinder diameter is 0.6m to 3.2m specifications of the product, the mill is equipped with ceramic lining plate, each loading capacity of 0.05ton-15 tons, supporting the host power 2.2-75kW, cylinder speed 13-50(r/min), suitable for special requirements of small batch of materials grinding.

Specifications: with a diameter of 600×700- 3200×4600

Loading capacity: 0.05-15 tons/time

Application: Suitable for mixing and grinding of common and special materials.

Ceramic ball mill product introduction

Ceramic ball mill is a kind of ball mill, and the difference between it and the general ball mill is that its liner is made of ceramic, its capacity is small, suitable for mixing and grinding of small batch materials, both dry and wet grinding.

Outstanding advantage

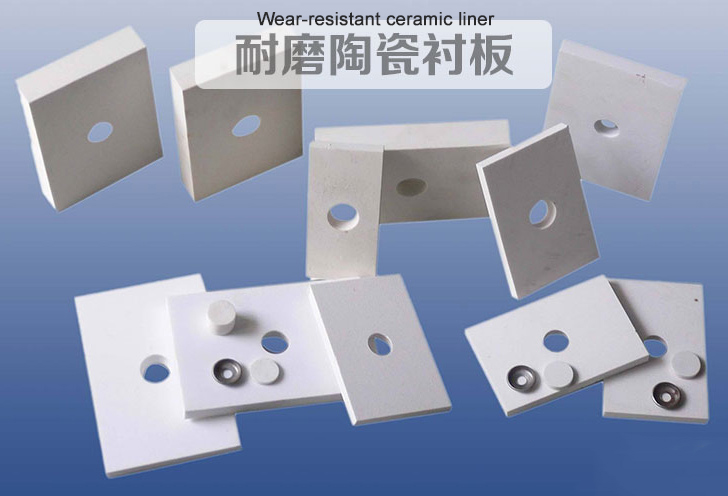

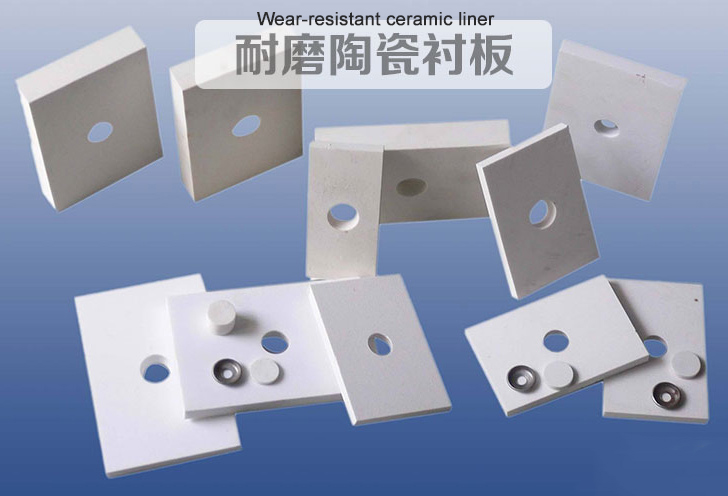

1, the type of liner can be changed: ceramic ball mill according to the production of different materials, can use different liner to meet different needs;

2, uniform product particle size: Because the ceramic ball mill discharge port has a grate to control its discharge particle size, too large material is difficult to discharge from the discharge port, so the product large material content is less, and the material particles that meet the requirements are more;

3, small footprint: compared with other ball mills, the length of the ceramic ball mill is short, so its footprint is small, can reduce the cost of land input;

4, stable operation: the transmission device of the ceramic ball mill adopts closed gear, so it enhances the stability of transmission.

Working principle

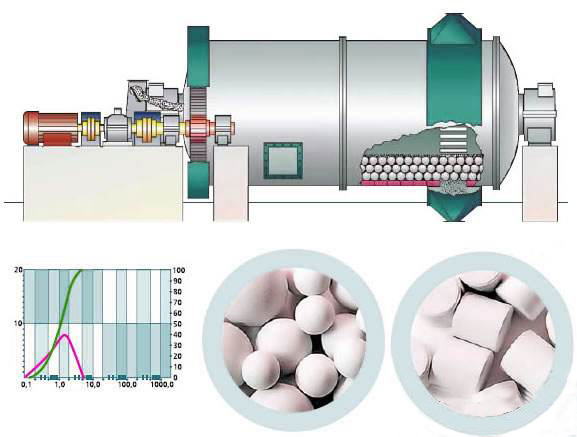

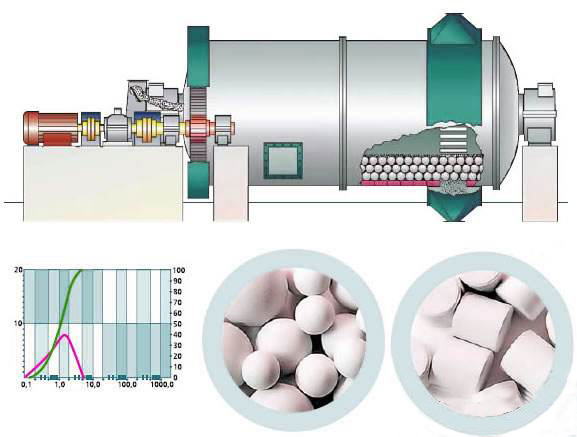

The motor drives the cylinder to rotate through the decelerating device, and the crushed ore and ceramic ball in the cylinder body are brought to a certain height by the friction and centrifugal force when the cylinder is rotating by the lining plate due to the action of gravity, and the ore is gradually crushed under the impact and grinding. The crushed ore is discharged out of the cylinder through the discharge section. After the discharged minerals are graded into qualified products in the spiral classifier, the coarse sand is returned to the ball mill through the combined feeder to continue grinding. The feeder feeds continuously and evenly, the ore enters the mill continuously and evenly through the combined feeder, and the ground material is continuously discharged from the ceramic ball mill.

Ceramic ball mill installation method:

When installing the ball mill, the main bearing should be installed first. In order to avoid aggravating the wear of the shoulder and bearing liner of the hollow journal, the elevation difference of the base plate of the two main bearings should not exceed 0.25 mm per meter length.

Secondly, the installation of the cylinder of the ball mill, combined with the specific conditions, can be pre-assembled the entire cylinder directly installed, can also be installed in several parts, and should be checked and adjusted the journal and the center line of the ball mill, the concentric error must be guaranteed in each meter length should be less than 0.25 mm.

Then install the transmission parts (pinion, shaft, coupling, reducer, motor, etc.).

During the installation process, it should be measured and adjusted according to the product technical standards. Check the radial swing of the gear ring and the meshing performance of the pinion; The concentricity of the reducer and pinion; And the concentricity of the motor and the reducer. When all the installation is in line with the requirements, the foundation bolts and main bearing bottom plate can be irrigated.

Technical parameter

| Model number | Loading capacity (tons/time) | Cylinder speed (RPM) | Reference power (kW) |

| 600×700 | 0.05 | 41.87 | 4 |

| 800×600 | 0.075 | 42 | 4.5 |

| 900×1200 | 0.2 | 38.5 | 5.5 |

| 1300×1500 | 0.5 | 33 | 7.5 |

| 1500×1800 | 1.2 | 28.5 | 11 |

| 1800×2000 | 1.5 | 24 | 15 |

| 2600×2800 | 5 | 16.5 | 37 |

| 3000×3800 | 10 | 14.5 | 57.2 |

| 3200×4600 | 15 | 13.5 | 75 |

| Ceramic, silica, rubber, metal (the supporting power will vary depending on the quality of the lining plate and the grinding material used) |