Ceramisite production line

Our company has been engaged in the production of green ceramic equipment since the establishment of the factory, in the sludge and other solid waste disposal, actively research and development, improve the process, the success of metallurgy, chemical, building materials technology through each other, the development of suitable for the use of ceramic production line of energy saving, environmental protection equipment, for the construction of new environmental protection and energy saving ceramic opened up a new process route.

Our company can provide a full set of ceramic production line equipment, process and technical support; And has a full set of pilot production line, can meet the customer's first experiment before putting into production, the experiment is successful and then put into production.

Capacity: 50,000-600,000 m3 / year

Applicable materials: clay, shale, sewage sludge, municipal sludge, industrial sludge, leather sludge, electroplating sludge, heavy metal sludge, construction waste soil, sand washing mud, pickling sludge, printing and dyeing sludge, paper sludge, oil well sludge, red mud, silt, contaminated soil, fly ash, slag, coal gangue, drilling cuttings, raw materials for old brick factory transformation, etc

Calcination temperature: 1100-1200℃

Main equipment: plug-in rotary kiln, single barrel cooling machine, crusher, double shaft mixer, roll granulator, dust collector, etc

Fuel heat source: natural gas, biomass particles (rice husks), coal, gas mixed combustion, etc.

Outstanding advantage

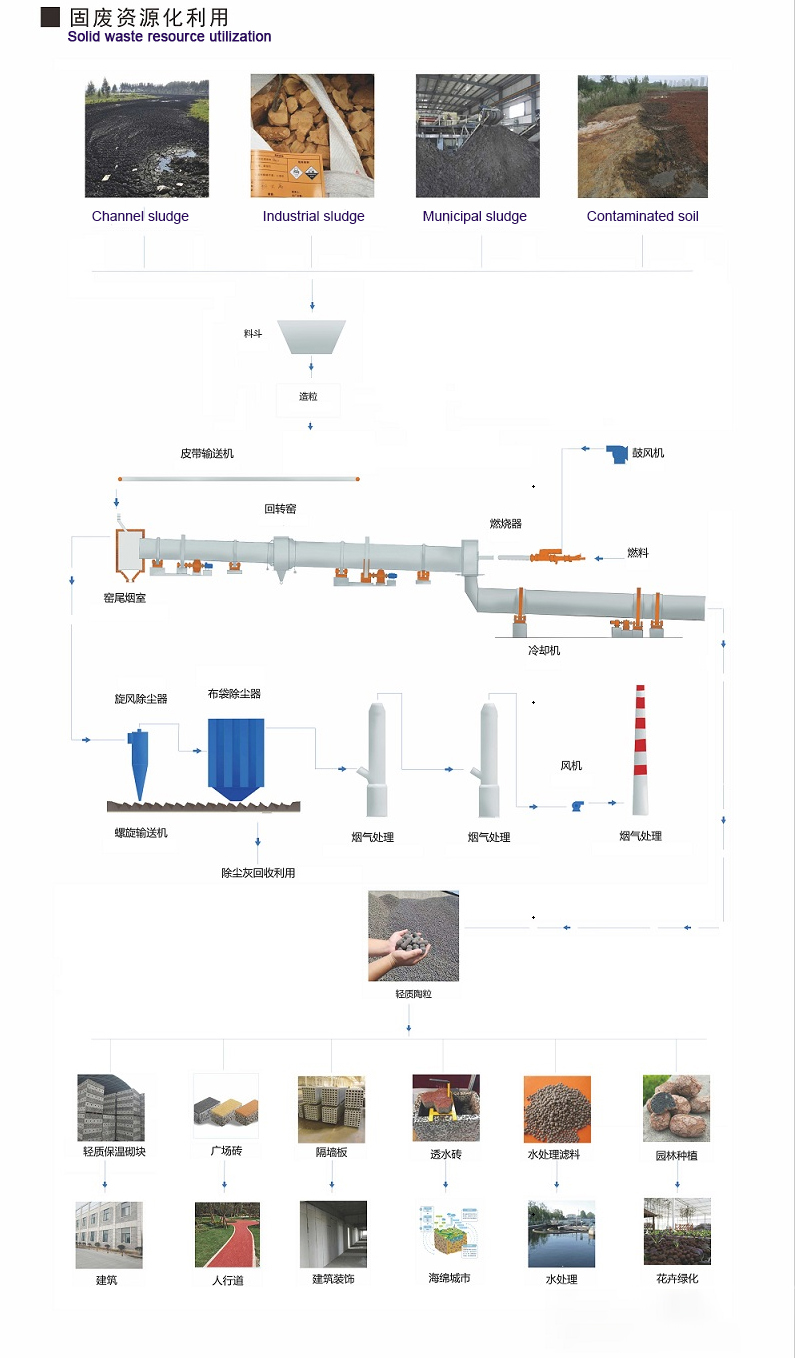

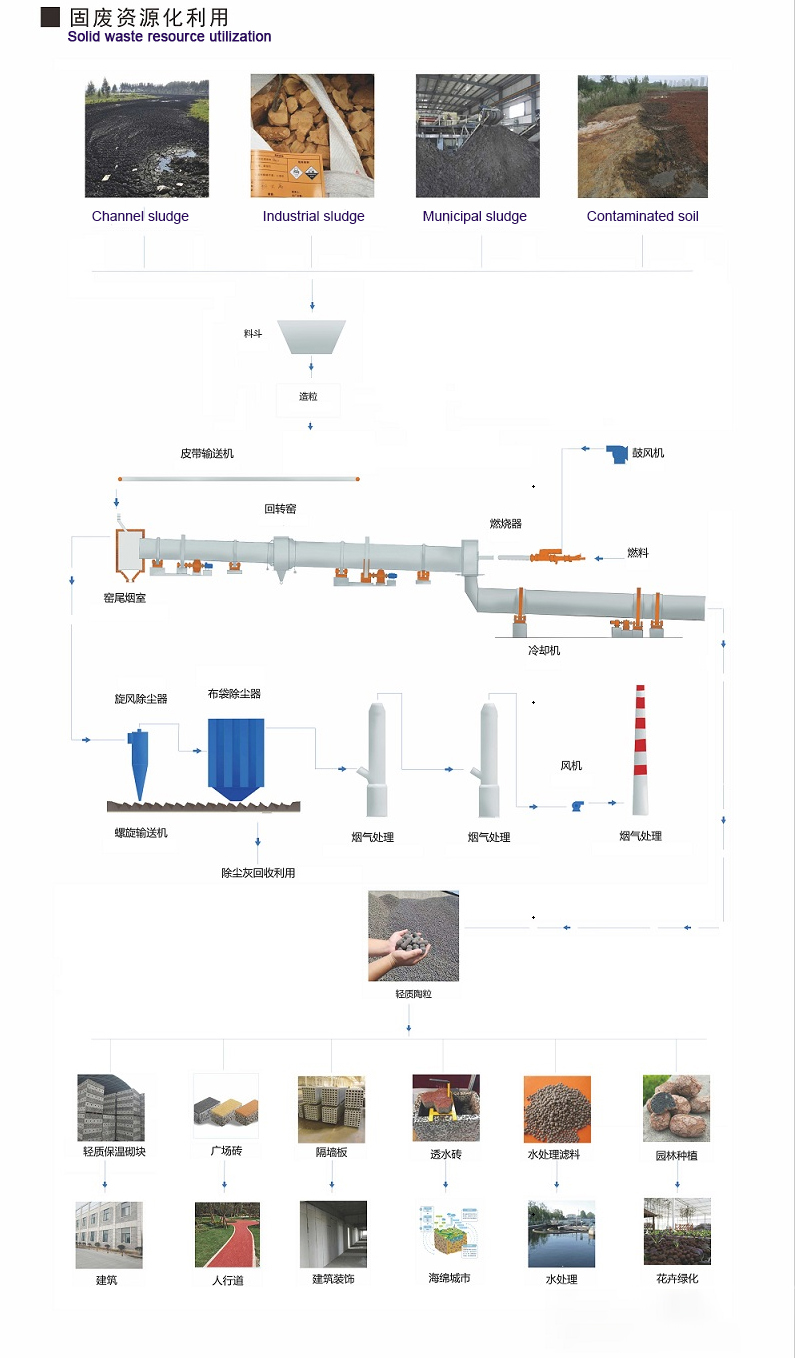

The main objective is to achieve the reduction, harmless and resource utilization of solid waste disposal such as sludge

1, The use of solid waste production of ceramics, not only can replace clay burning pottery, save land, waste into treasure, while high temperature sterilization, solidification of heavy metals, to avoid pollution.

2, From the overall project planning to the detailed process formula, process design, equipment design and manufacturing, engineering installation, commissioning, etc. to provide a complete whole industry chain services, with a complete solid and dangerous waste treatment system solutions.

3. The company's pilot test line can carry out raw material analysis, formulation design, sample preparation, roasting, pilot test and pilot test of various sludge ceramics.

Process flow

Ceramisite production process is as follows (taking sludge raw materials as an example) : sludge and clay and auxiliary materials → beating and crushing → proportioning → mixing and stirring → aging → granulation → roasting → cooling → finished product classification screening → stacking → transportation (bagging).

Technical parameter

| NO. | Specifications (m) | Productive capacity | Slope (%) | Cylinder speed (r/min) | Reduction gear | Motor |

| Hourly output (m3/h) | Annual output (10,000 m3/a) | TYPE | Power (k W) |

| 1 | Preheating kiln | φ1.25×18 | 2.95~3.94 | 1.8~2.4 | 4 | 1.0~5.0 | ZQ500 | YCT225-4A | 11 |

| Calcining kiln | φ1.6×14 | 1.0~5.0 | ZQ650 | YCT225-4B | 15 |

| 2 | Preheating kiln | φ1.55×20 | 4.36~5.81 | 2.67~3.5 | 4 | 1.0~5.0 | ZQ650 | YCT250-4A | 18.5 |

| Calcining kiln | φ1.9×16 | 1.0~5.0 | ZQ750 | YCT250-4B | 22 |

| 3 | Preheating kiln | φ1.8×22 | 5.9~7.87 | 13.61~4.8 | 4 | 1.0~5.0 | ZQ750 | YCT250-4B | 22 |

| Calcining kiln | φ2.2×18 | 1.0~5.0 | ZQ750 | YCT250-4B | 22 |

| 4 | Preheating kiln | φ2.0×24 | 7.42~9.88 | 4.54~6 | 4 | 1.0~5.0 | ZSY224 | YCT280-4B | 30 |

| Calcining kiln | φ2.5×20 | 1.0~5.0 | ZSY224 | YCT315-4A | 37 |

| 5 | Preheating kiln | φ3.0×20-φ2.5×12 | 9.5~17.51 | 8.04~10.7 | 4 | 1.0~5.0 | ZS1450 | YCT355-4B | 75 |

| Calcining kiln | φ3.0×22 | 1.0~5.0 | ZS1250 | YCT355-4A | 55 |

| 6 | Preheating kiln | φ3.2×20-φ2.8×14 | 13.9~16.2 | 10.0~11.5 | 4 | 1.0~5.0 | ZS1450 | YCT355-4A | 55 |

| Calcining kiln | φ3.0×22 | 1.0~5.0 | ZS1250 | YCT355-4A | 55 |