The fully automatic chewing gum production line can produce chewing gum of various shapes such as round, spherical, square, rectangular and sheet. The chewing gum making machine is reliable in production, flexible and easy to operate, and fully automated.

1.Fully automatic chewing gum production line

2. Core spherical chewing gum production line

3. Square chewing gum production line

4. Irregularly shaped chewing gum production line

5. Fully automatic xylitol chewing gum production line

6. Chewing gum type (Candy shape)

7. Working Principle of Chewing Gum Machines

8. Installation of the chewing gum production line

Fully automatic chewing gum production line

Fully automatic chewing gum production line

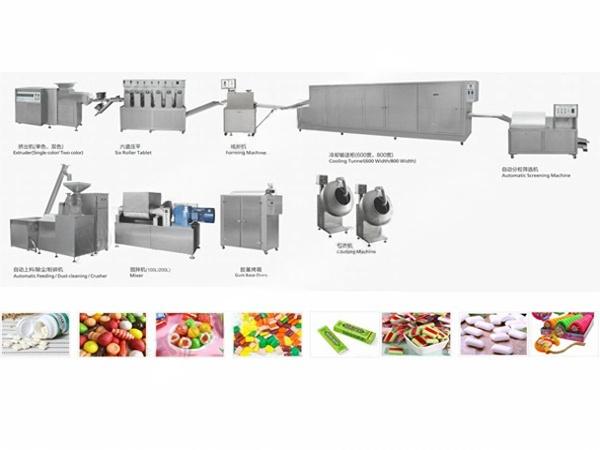

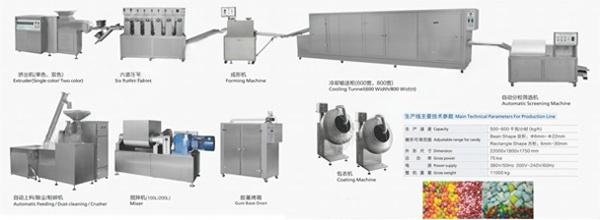

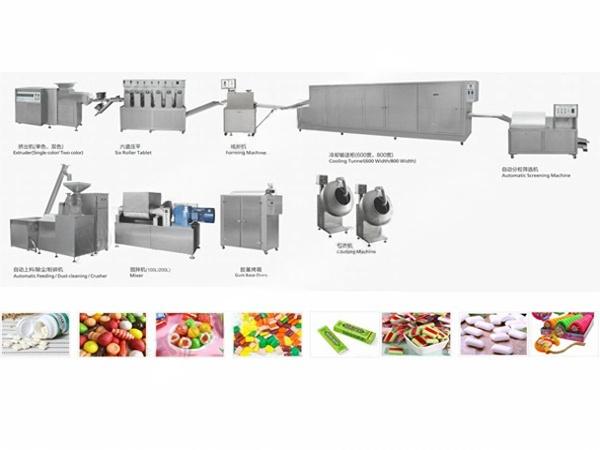

The fully automatic chewing gum production line is composed of a mixer, an extruder, six flattening machines, a forming machine, a cooling and conveying cabinet, an automatic pelletizer, a gum base oven and a coating machine, forming a fully automatic production line. It can produce chewing gum of various shapes (such as round, spherical, square, rectangular, sheet, etc.). The whole machine is productive and reliable, easy and flexible to operate, and automated. It is a processing equipment for manufacturing chewing gum.

The process flow of the fully automatic chewing gum production line

Mixer - Extruder - six-pass flattening - Forming machine - Cooling conveying cabinet - Automatic granulator - Adhesive base - Oven - Coating machine - Packaging machine

Main technical parameters of the production line

Production speed :500-600 kilograms per hour (kg/h)

Adjustable range of sugar shape: Bean shape: 6mm-22mm; Square :6mm- 30mm, spherical :6mm-22mm

Overall dimensions :22000x1800x1750mm

Total power efficiency :75 kw

Power supply :380V/50HZ, 200V-240V/60HZ

The total weight of the machine is 11,000 kg

Main technical parameters of the single machine

Automatic feeding/dust removal crusher: Power :17kw, Dimensions :3500x1300x2200mm, Weight :400kg

Rubber-based oven: Power :18kw, Dimensions :1600x600x1700mm, Weight :300kg

Mixer -100L: Power: 20kw, Dimensions :2300x860x1550mm, Weight :1500kg

Mixer -200L: Power: 24kw, Dimensions :2650x1000x1650mm, Weight :2000kg

Extruder - Single color: Power: 15kw, Dimensions :2500x900x1500mm, Weight :1000kg

Extruder - Two-color: Power :22 kw, Dimensions :2600x1150x1500mm, Weight :2200kg

Six-channel flattening t: Power :5 kw, Dimensions :5100x950x1880mm, Weight :2000kg

Forming machine: Power: 2.2kw, External dimensions :1800x780x1650mm, Weight :800kg

Cooling conveyor cabinet -600 width: Power :20 kw, external dimensions :8850x1900x1850mm, weight :2500kg

Cooling conveyor cabinet -800 width: Power :22 kw, external dimensions :8850x2100x1850mm, Weight :2700kg

Automatic bud separation and screening machine: Power :3 kw, external dimensions :2200x1000x1400mm, Weight :350kg

Sugar coating machine: Power :2 kw, Dimensions :1050x1050x1600mm, Weight :350kg

2. Core spherical chewing gum production line

Core spherical chewing gum production line

The spherical chewing gum production line is composed of a mixer, an extruder, a cooling conveyor cabinet, a three-layer conveyor belt, six forming machines, a sugar coating machine, two square paste forming machines, and a gum base oven. It can produce hollow candies with powder and paste in various shapes such as spherical, strawberry-shaped, olive-shaped, and cylindrical.

The technological process of the core spherical chewing gum production line

Mixer - Extruder - Cooling conveyor cabinet - Three-layer conveyor belt - Forming machine - Sugar coating machine - Square sauce filling forming machine - Gum base oven

Main technical parameters of the production line

Production speed :400-650 kilograms per hour

Sugar shape diameter :10-25mm

Dimensions :15000x4000x1500mm

Total power: 82kw

Power supply :380V

The total weight of the machine is 8,850 kg

Main technical parameters of the single machine

Automatic feeding/dust removal crusher: Power :17kw, Dimensions :3500x1300x2200mm, Weight :400kg

Rubber-based oven: Power :18kw, Dimensions :1600x600x1700mm, Weight :300kg

Mixer -100L: Power :20kw, Dimensions :2300x860x1550mm, Weight :1500kg

Mixer -200L: Power :24kw, Dimensions :2650x1000x1650mm, Weight :2000kg

Extruder - Single color: Power :15kw, Dimensions :2500x900x1500mm, Weight :1000kg

Extruder - Two-color: Power :22kw, Dimensions :2600x1150x1500mm, Weight :2200kg

Sandwich pump: Power :3kw, Dimensions :1600x550x1650mm, Weight :300kg

Cooling conveyor cabinet -600 width: Power :20kw, external dimensions :8850x1900x1850mm, Weight :2500kg

Cooling conveyor cabinet -800 width: Power :22kw, external dimensions :8850x2100x1850mm, Weight :2700kg

Three-layer conveyor belt: Power :2.3kw, Dimensions :10500x900x1450mm, Weight :300kg

Forming machine: Power :1.5kw, External dimensions :1320x950x1600mm, Weight :400kg

Square sauce filling machine: Power :2.2kw, external dimensions :1200x1200x1300mm, Weight :650kg

Sugar coating machine: Power :2kw, Dimensions :1050x1050x1600mm, Weight :350kg

3. Square chewing gum production line

Fully automatic square chewing gum production line

Main performance

The fully automatic square chewing gum production line is an automatic production line integrating shaping, cutting and packaging. It is suitable for the shaping, cutting and packaging of square chewing gum, rectangular chewing gum and sheet chewing gum. Products of various shapes and specifications can be produced according to customers' requirements. Such as chewing gum, sheet shapes of Swiss sugar, rectangular and round fillings, color fillings, fillings, etc.

The process flow of the fully automatic square chewing gum production line

Automatic feeding/dust removal/pulverizer - mixer - extruder - cooling conveyor cabinet - block pillow packaging machine - low-temperature double vacuum gas-filled mixing pot - glue-based oven

Main technical parameters of the production line

Production speed :750-850 kilograms per hour

Power supply :380V

Total power efficiency :143 kw

Overall dimensions :17300X5500X1800mm

Adjustable range of sugar shape :18-80mm

The total weight of the machine is 15,000 kg

Main technical parameters of the single machine

Automatic feeding/dust removal/pulverizer: Power :17 kw, Dimensions :3500x1300x2200mm, Weight :400kg.

Mixer -100L: Power :20kw, Dimensions :2300x860x1550mm, Weight :1500kg

Mixer -200L: Power :24kw, Dimensions :2650x1000x1650mm, Weight :2000kg

Extruder r- Monochrome: Main power:15kw, External dimensions :2500x900x1500mm, Weight :1000kg

Extruder - Two-color: Main power: 22kw, External dimensions :2600x1150x1500mm, Weight: 2200kg

Sandwich pump: Power :3 kw, Dimensions :1600x550x1650mm, Weight :300kg

Cooling conveyor cabinet -600 width: Power :20kw, external dimensions :8850x1900x1850mm, Weight: 2500kg

Cooling conveyor cabinet -800 width Power :22kw, external dimensions :8850x2100x1850mm, Weight :2700kg

Block pillow packaging machine (unit): Power :4kw, External dimensions :2150x900x1500mm, Weight :980kg

Low-temperature double vacuum gas-filled stirring pot: Power: 29kw, Dimensions: 3300x1600x3200mm, Weight: 2500kg

Rubber-based oven: Power :18kw, Dimensions :1600x600x1700mm, Weight: 300kg

4. Irregularly shaped chewing gum production line

Irregularly shaped chewing gum production line

Parameters

Output :150-300kg/h

Mixer 100L:7.5kW, dimensions :1900x660x1200mm, Overall weight :1200kg

Mixing machine 200L:18.5kW, external dimensions :2250x950x1550mm, whole machine weight :2000kg

Tablet pressing machine :5.5kW, external dimensions :6200x1000x1500mm. The total weight of the machine is 3000kg

The irregular-shaped chewing gum production line is composed of single units such as a mixer, extruder, forming machine, cooling cabinet, and tube coating machine

5. Fully automatic xylitol chewing gum production line

Fully automatic xylitol chewing gum production line

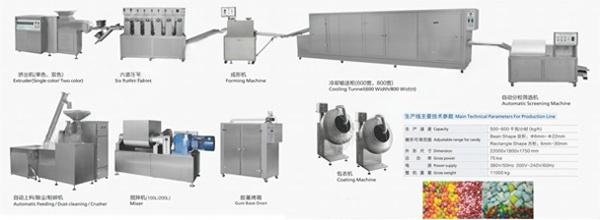

The fully automatic xylitol chewing gum production line is composed of a mixer, an extruder, six flattening machines, a forming machine, a cooling and conveying cabinet, an automatic pelletizer, a gum base oven and a coating machine. The whole machine is reliable in production, flexible and easy to operate, and fully automated. It is a processing equipment for xylitol chewing gum.

The process flow of the fully automatic xylitol chewing gum production line

Mixer - Extruder - six-pass flattening - Forming machine - Cooling conveying cabinet - Automatic granulator - Adhesive base - Oven - Coating machine - Packaging machine

Main technical parameters of the production line

Production speed :500-600 kilograms per hour (kg/h)

Adjustable range of sugar shape: Bean shape: 6mm-22mm; Square :6mm- 30mm, spherical :6mm-22mm

Overall dimensions: 22000x1800x1750mm

Total power efficiency :75 kw

Power supply :380V/50HZ, 200V-240V/60HZ

The total weight of the machine is 11,000 kg

Main equipment

Extruder (single color)

This equipment is used for extruding chewing gum. The hopper is made of stainless steel, and the extrusion head in the extruder is made of high-hardness steel and coated with polytetrafluoroethylene. The extrusion head is kept warm through hot water circulation, which can ensure the temperature and softness of the rubber base.

Power :15kw

Dimensions :2500*900*1500mm

Machine weight :1000kg

Extruder (two-color)

Power :22kw

Overall dimensions :2600*1150*1500mm

Machine weight :2200kg

Forming machine

Power :1.5kw

Overall dimensions :1320*950*1600mm

Machine weight :400kg

Chewing gum of different sizes can be produced according to the requirements of different customers.

Coating machine

Power :2.2kw

Dimensions :1600*730*1450mm

Machine weight :350kg

Used for polishing the surface of candies

Structural characteristics:

This machine is composed of the main body, worm gear box, sugar coating pot, heating device, fan, electrical appliances and other parts. It is driven by an electric motor through a V-belt to rotate the worm gear and worm, which in turn rotates the sugar coating pot. Under the action of centrifugal force, the materials roll up and down and rub against each other in the pot, achieving the effects of sugar coating mixing, pill-making and polishing.

Cooling conveying cabinet

Cooling conveying cabinet (600)

Power :20kw

Dimensions :8850*1900*1850mm

Machine weight :2500kg

Cooling conveying cabinet (800)

Power :22kw

Overall dimensions :8850*2100*1850mm

Machine weight :2700kg

Blender

This equipment is used for mixing and stirring the raw materials for gum production, and it has a high stirring efficiency

Blender (100)

Power :20kw

Overall dimensions :2300*860*1550mm

Machine weight :1500kg

Blender (200)

Power :24kw

Overall dimensions :2650*1000*1650mm

Machine weight :2000kg

Rubber-based oven

Power :18kw

Overall dimensions :1600*600*1700mm

Machine weight :300kg

Square-shaped sauce filling forming machine

Power :2.2kw

Overall dimensions :1200*1200*1300mm

Machine weight :650kg

6. Chewing gum type (Candy shape)

7. Working Principle of Chewing Gum Machines

The chewing gum production line consists of a mixer, an extruder, a forming machine, a cooler and a sugar coating machine. It produces chewing gum candies of various shapes, such as spherical, watermelon-shaped, oval, square, long sheet-shaped, etc. The products produced by this equipment are aesthetically pleasing in shape, the machine performance is stable, and the operation and maintenance are simple.

The gum base is prepared in advance through a melting and filtering or filtration process. Next, other components (such as nutritional and non-nutritional sweeteners and flavorings) are added to the gum base sugar base agent until the warm mixture thickens like dough. During this mixing process, the gelatinous sugar base agent mixture is heated to increase the entropy of the polymer, thereby achieving a more uniform dispersion of the components. Then, extrusion implementation techniques are used to make the chewing gum smooth, shaped and formed. Next, chewing gum undergoes a shaping process determined by the type of chewing gum and consumer demand. For instance, a vertical cutting machine is used to directly cut and wrap (block or cube) parts from the extruder. Tablet pressing is a technique often used in adhesives, thick plate adhesives and sheet adhesives. Next, sprinkle the glue with powdered polyol for conditioning, or before sending it into packaging, apply it using a temperature-controlled coating basin by coating in subsequent layers.

8. Installation of the chewing gum production line

We will send engineers to help you install the machine