The fully automatic chocolate production line includes the casting chocolate block production line, the stamping chocolate candy production line, the extrusion chocolate bean production line, and the machines for making chocolate candies, chocolate energy bars, chocolate blocks, chocolate snickers bars, and chocolate beans

Chocolate pouring production line

Fully automatic single-head chocolate pouring production line

Double-head chocolate casting production line

Three-head chocolate pouring production line

2. Chocolate candy production line

3. Chocolate Snickers rack production line

4. Chocolate bean production line

5. Chocolate energy bar production line

6. Nut chocolate production line

7. Fully automatic chocolate candy bar production line

8. Chocolate forming production line

9. Chocolate types (candy shapes) and applications

10. Working Principle of Chocolate candy Machine

11. Installation of the chocolate production line

1.Chocolate pouring production line

Fully automatic single-head, double-head and triple-head chocolate casting production lines

Main uses:

The chocolate pouring forming machine is a device used for manufacturing chocolate products. It integrates the processes of baking molds, pouring, shaking, flattening, flipping molds, cooling, demolding, and conveying into one, and is fully automatically controlled by PLC. It can produce pure chocolate, shell-filled and two-color chocolate products from top to bottom, left to right. Two or three heads can work independently or simultaneously.

Model: Fully automatic single-head chocolate Pouring Production Line

Output :1.5-3.0Tons/shift

Pouring speed :8-15Moulds/min

Weight of chocolate products - Pure chocolate :0-600g

Weight of chocolate products - Filled chocolate :15-30%

The temperature inside the freezer is 5-10°C

Operating ambient temperature :22-25°C

Refrigeration power: 15-horsepower water-cooled refrigeration unit

Cooling method: Closed-loop cooling by centrifuge is adopted

Voltage :380V/50Hz

The total power of the machine is 28kw

Template size and quantity :300*225*30mm, 220 pieces

Overall weight (kg): 8,500 kg

Overall dimensions (L*W*H):16000*1500*2000mm

Model: Double-head chocolate pouring production Line

Output :1.5-3.0Tons/shift

Pouring speed :8-15Moulds/min

Weight of chocolate products - Pure chocolate :0-600g

Weight of chocolate products - Filled chocolate :15-30%

The temperature inside the freezer is 5-10°C

Operating ambient temperature :22-25°C

Refrigeration power: 15-horsepower water-cooled refrigeration unit

Cooling method: Closed-loop cooling by centrifuge is adopted

Voltage :380V/50Hz

Overall power :32.5kw

Template size and quantity :300*225*30mm, 220 pieces

Overall weight (kg): 11,500 kg

Overall dimensions (L*W*H):19000*1100*1800mm

Model: Three-head chocolate pouring production line

Output :1.5-3.0Tons/shift

Pouring speed :8-15Moulds/min

Weight of chocolate products - Pure chocolate :0-600g

Weight of chocolate products - Filled chocolate :15-30%

The temperature inside the freezer is 5-10°C

Operating ambient temperature :22-25°C

Refrigeration power: 20-horsepower water-cooled refrigeration unit

Cooling method: Closed-loop cooling by centrifuge is adopted

Voltage :380V/50Hz

The overall power of the machine is 43kw

Template size and quantity :300*225*30mm, 360 pieces

Overall weight (kg): 15,000 kg

Overall dimensions (L*W*H):45000*1200*2200mm

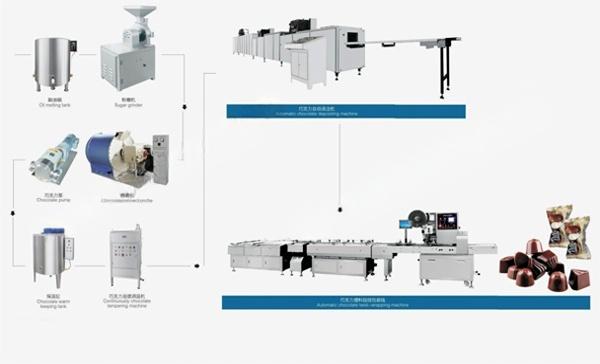

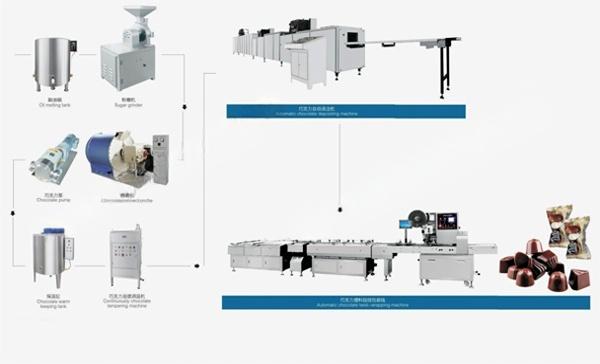

2. Chocolate candy production line

The technological process of the chocolate candy production line

Melting oil pot - Sugar powder machine - Fine grinding machine - chocolate pump - Heat preservation tank - chocolate continuous temperature control machine - Chocolate automatic pouring machine - Chocolate material arrangement, kinking and packaging machine

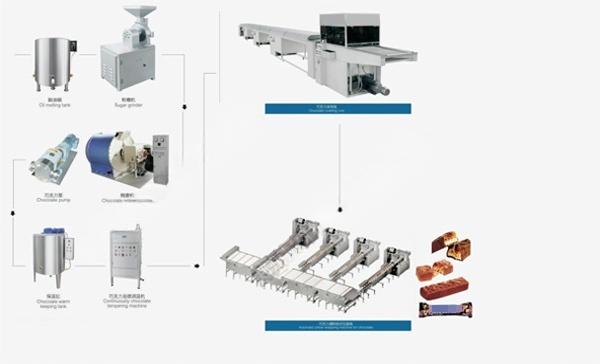

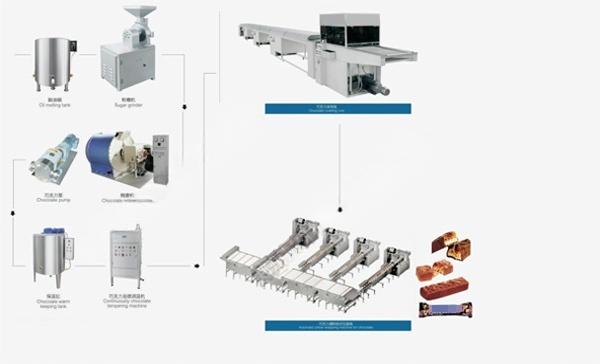

3. Chocolate Snickers rack production line

Process flow chart of the chocolate Snickers rack production line

Melting oil pot - Sugar powder machine - Fine grinding machine - chocolate pump - heat preservation tank - chocolate continuous temperature control machine - chocolate coating line - chocolate material arrangement pillow packaging machine

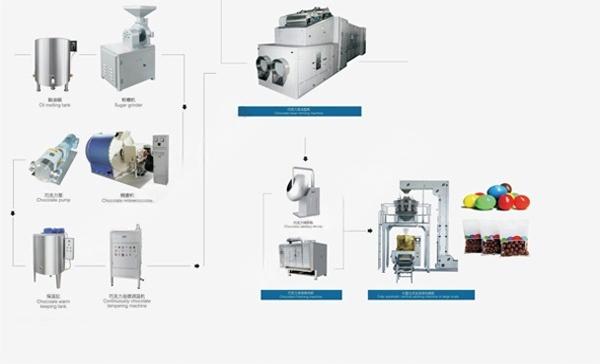

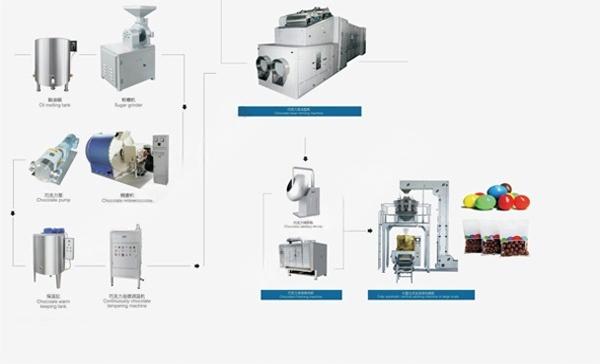

4. Chocolate bean production line

Process flow chart of the chocolate bean production line

Oil melting pot - Sugar powder machine - Fine grinding machine - chocolate pump - Heat preservation tank - chocolate continuous temperature control machine - chocolate bean forming machine - chocolate polishing machine - chocolate coating machine - chocolate packaging machine

Main performance

There are two different processing methods for chocolate beans. One is formed from chocolate powder, and the other is formed from chocolate liquid. The complete chocolate production line, composed of fine grinding cylinders, insulated buckets, crushers, vibrating screens, forming machines, chillers and pelletizers, etc., is suitable for the production of high-quality chocolates of various shapes (such as round chips, bean-shaped, olive-shaped, etc.).

Model: ZY-400

Mesh belt width (mm):140

Mesh belt speed (min):1-6

Refrigeration unit (set):2

Tunnel length (m):10

Tunnel temperature (℃):2-10

Total machine power (kw):10

Weight (kg):1800

Overall dimensions (L*W*H)(mm):13160*700*1500

Model: ZY-600

Mesh belt width (mm):600

Mesh belt speed (min):1-6

Refrigeration unit (set):3

Tunnel length (m):14

Tunnel temperature (℃):2-10

Total machine power (kw):16.5

Weight (kg):2300

Overall dimensions (L*W*H)(mm):18500*950*1800

Model: ZY-900

Mesh belt width (mm):900

Mesh belt speed (min):1-6

Refrigeration unit (set):4

Tunnel length (m):18

Tunnel temperature (℃):2-10

Total machine power (kw):22.87

Weight (kg):3200

Overall dimensions (L*W*H)(mm):21500*1200*1800

Model: ZY-1200

Mesh belt width (mm):1200

Mesh belt speed (min):1-6

Refrigeration unit (set):5

Tunnel length (m):22

Tunnel temperature (℃):2-10

Total machine power (kw):28.5

Weight (kg):4050

Overall dimensions (L*W*H)(mm):25500*1450*1800

5. Chocolate energy bar production line

Chocolate energy bar production line

Technical parameters

Production capacity: 400-600kg/h

- Finished product range: 40-150mm

Total power: 8.9kw

- Machine weight: 2880kg

- Dimensions: 1390 x 1360 x 1400mm

Uses and Characteristics

This machine is suitable for the molding of products such as mixed grains, fruit red sticks, fruit strips, and nutrition bars, which are made from sugar base as raw materials and processed after boiling as adhesives. This line is composed of a flattening machine (extruder as an option), a cooling conveying cabinet (refrigeration equipment as an option), a division and expansion conveyor, a finished product cutting machine, and a separation conveying machine (three-phase variable frequency motor or servo motor drive as an option). The main features of this machine are the rapid switching of cutting lengths of other specifications, the computer human-machine operation interface, and convenient maintenance.

6. Nut chocolate production line

Nut chocolate production line

The continuous casting and forming production line for nuts and chocolates is a production line for mixed nuts and chocolate candies. The production of chocolate candies that can be mixed with various fruits/nuts such as preserved plums and almonds. This machine features automatic addition of nut chocolate and continuous pouring production operation. The added materials are precisely positioned, not prone to breakage, easy to replenish, and have a fast feeding speed. It is an equipment for producing various types of nut mixed candies.

Model: ZY-360

Output :360kg/h

Power (sugar boiling machine):16kw

Power (casting machine):17kw

Compressed air consumption :0.5m ³ /min

Compressed air pressure :0.4-0.6Mpa

Steam consumption :450kg/h

Steam pressure :0.6-0.8Mpa

Consumption :2200L/h

(L*W*H) Dimensions :13500*2000*2700mm

Weight :6000kg

Model: ZY-500

Output :500kg/h

Power (sugar boiling machine):23kw

Power (casting machine):19kw

Compressed air consumption :0.5m ³ /min

Compressed air pressure :0.4-0.6Mpa

Steam consumption :500kg/h

Steam pressure :0.6-0.8Mpa

Consumption :2200L/h

(L*W*H) Dimensions :13500*2500*2700mm

Weight: 7,500 KGS

Model: ZY-720

Output :720kg/h

Power (sugar boiling machine):23kw

Power (casting machine):23kw

Compressed air consumption :0.5m ³ /min

Compressed air pressure :0.4-0.6Mpa

Steam consumption :600kg/h

Steam pressure :0.6-0.8Mpa

Consumption :2200L/h

(L*W*H) Dimensions :13500*2800*2700mm

Weight :8000kgs

7. Fully automatic chocolate candy bar production line

Fully automatic chocolate candy bar production line

Technical parameters

Production capacity: 300kg/h

Total power: 8.9kw

- Forming range: 40-100mm

- Machine weight: 2880kg

- Dimensions: 12000*1360*1400

Purpose and features

This machine is suitable for the forming of products such as mixed grains, fruit red sticks, fruit strips, and nutrition bars, which are made from sugar base as raw materials and processed after boiling as adhesives. This line is composed of a split expansion conveyor, a finished product cutting machine, and a separation conveyor (three-phase variable frequency motor or servo motor drive is an option). The main features of this machine are the rapid switching of cutting lengths of other specifications, the computer human-machine operation interface, and convenient maintenance.

8. Chocolate forming production line

Chocolate forming production line

Main performance

This machine is a device for chocolate casting and shaping, integrating mechanical and electrical control. The entire production process includes fully automatic working procedures such as casting, vibrating the mold, cooling, demolding, conveying, and drying the mold.

This machine can produce pure chocolate, filled chocolate, soft-filled granular cast chocolate, left and right two-color chocolate, four-color chocolate, and chocolate production equipment

Main technical parameters of the production line

Power supply :380V/50HZ

Total power :22kw

Production speed :300-500 kilograms per hour

Overall dimensions :18000x1200x2200 mm

Template specification :470 x 200 x 30 mm

Template quantity :280 pieces (PCS)

Weight: 6,200 kg

Main equipment

Vacuum continuous boiling pot

It has the functions of automatic sugar boiling and automatic temperature control, and the syrup boiled has high transparency

①. Sugar dissolving pot

Capacity (L):300

Weight (kg):280

Overall dimensions (mm):1100*1100*1700

②. Sugar storage tank

Capacity (L):300

Weight (kg):220

Overall dimensions (mm):740*740*1250

③. Technical parameters

Production capacity (kg/h):350-400

Heating area (m³):2.45

Steam pressure (MPa):0.7-1.0

Steam consumption (kg/h): approximately 100

Sugar solution entry temperature (°C):110-115

Discharge temperature (°C):135-145

Power - fixed displacement pump (kw):0.75

Matching power - Vacuum pump (kw):5.5

Overall dimensions (mm):1900*1700*2300

Overall weight (kg):800

Vacuum continuous boiling machine

Main components: Syrup pump, heater, syrup inlet, secondary steam discharge system, needle valve, vacuum steam chamber, unloading control system, rotary pot, vacuum system.

Working principle:

The purpose of boiling sugar is to remove most of the water in the sugar solution after dissolving sugar, so that the sugar paste can reach a very high concentration and retain less water. To turn the sugar solution into a thick sugar paste, the increase in concentration must be achieved through a boiling and evaporation process with an increasing temperature gradient. This process is achieved through continuous boiling and processing, thus it is called boiling sugar. The water in the sugar liquid needs to escape from the liquid surface and enter the space to be discharged. The faster the escape speed, the faster the boiling speed. Under vacuum conditions, sugar solution can boil and evaporate at a relatively low temperature, and the evaporation rate is fast. Operating procedures: The vacuum sugar boiling process is generally divided into three stages: preheating, evaporation and vacuum concentration. The preheating stage is to increase the temperature and concentration of the sugar solution and shorten the cycle of vacuum sugar boiling. During the evaporation stage, the remaining water in the sugar solution is removed.

Sugar boiling equipment is actually a set of evaporation and concentration equipment. The function of the heater is to provide an appropriate heat source and sufficient heat transfer area to heat the sugar liquid to the boiling state. The evaporator enables the sugar solution to quickly remove water in a boiling state, and the transfer pump stably transcribe the sugar solution throughout the entire process to achieve continuous and balanced production.

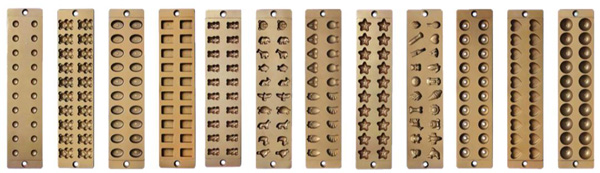

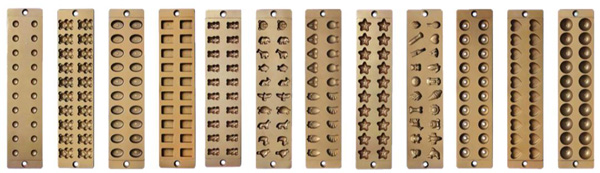

Mold

Customers can put forward their own design concepts, and we will complete the mold drawings. During the operation of the machine, just by changing different molds, candies of different shapes can be produced.

Casting mold forming machine.

Main components: conveyor belt, model tray, sugar injection nozzle, sugar pouring pump, storage tank, cooling device.

This machine is controlled by a PLC system, and parameters such as temperature and pouring speed can all be controlled on the touch screen. Meanwhile, variable frequency speed regulation is adopted to control the accurate flow rate of the sugar liquid, ensuring the stability of the sugar paste quality.

During the mold casting process, when the boiled sugar paste is still in a flowing state, the liquid sugar paste is quantitatively injected into the continuously running model tray, then rapidly cooled and shaped. After that, it is separated from the model tray and sent to the packaging machine along the conveyor belt for packaging.

Working principle: The function of the sugar pump is to push the sugar paste into the sugar injection nozzle. It is composed of two cylinders assembled together. The outer cylinder is a fixed cylinder, with a tank channel on the side that is connected to the storage trough, and a small hole at the bottom that is connected to the sugar injection nozzle. The inner cylinder is an opening and closing cylinder. There is a connecting handle in the middle of the inner and outer periphery of the cylinder, which is connected to the lever that swings left and right. There is a small hole on the side and a small hole at the bottom of the cylinder. When swinging, the small hole at the bottom closes with the small hole at the bottom of the outer cylinder, and the small hole on the side connects with the channel of the storage trough. When the small hole on the side closes with the empty opening on the side of the outer cylinder, the sugar filling nozzle of the wine barrel is connected with the small hole at the bottom. Inside the opening and closing cylinder, there is a piston. When the piston moves up and down, it can draw in air and press the sugar paste against the sugar injection nozzle. The size of the piston's movement distance determines the amount of sugar paste discharged. The piston's movement distance can be adjusted according to the size of the sugar block. At the bottom of each sugar pump, there is a sugar injection nozzle, which equates the number of sugar models.

Chocolate coating machine

Main uses

This machine is a dedicated equipment for producing various types of chocolate. It can dip and coat chocolate paste on the surface of various foods, such as wafers, biscuits, egg rolls, egg yolk pies, puffed foods, etc., to form a variety of chocolate products with unique flavors.

9. Chocolate types (candy shapes) and applications

10. Working Principle of Chocolate candy Machine

Chocolate forming: Casting molding can process chocolates of various shapes according to molds, with a wide range of applications. During casting molding, when the chocolate paste is still in an active state after being cooked, the liquid chocolate paste is quantitatively injected into the continuously running mold tray, then rapidly cooled and shaped, and finally separated from the mold tray and sent to the packaging machine along the conveyor belt for packaging.

Chocolate extrusion molding: This production line is composed of a mixer, an extruder, a forming machine, a cooling and conveying cabinet, an automatic pelletizer, a gel base oven and a coating machine, forming a fully automatic production line. It can produce candies of various shapes (such as square, rectangular, sheet, etc.). The whole machine is productive and reliable, easy and flexible to operate, and has a high degree of automation.

11. Installation of the chocolate production line

We will send engineers to help you install the machine