Clay ceramisite production line production technology

Clay ceramisite is made of clay with appropriate composition as raw material, and some other materials need to be added when the composition is not suitable, which is processed into granulated and expanded at high temperature in the rotary kiln.

Introduction of clay ceramide production line

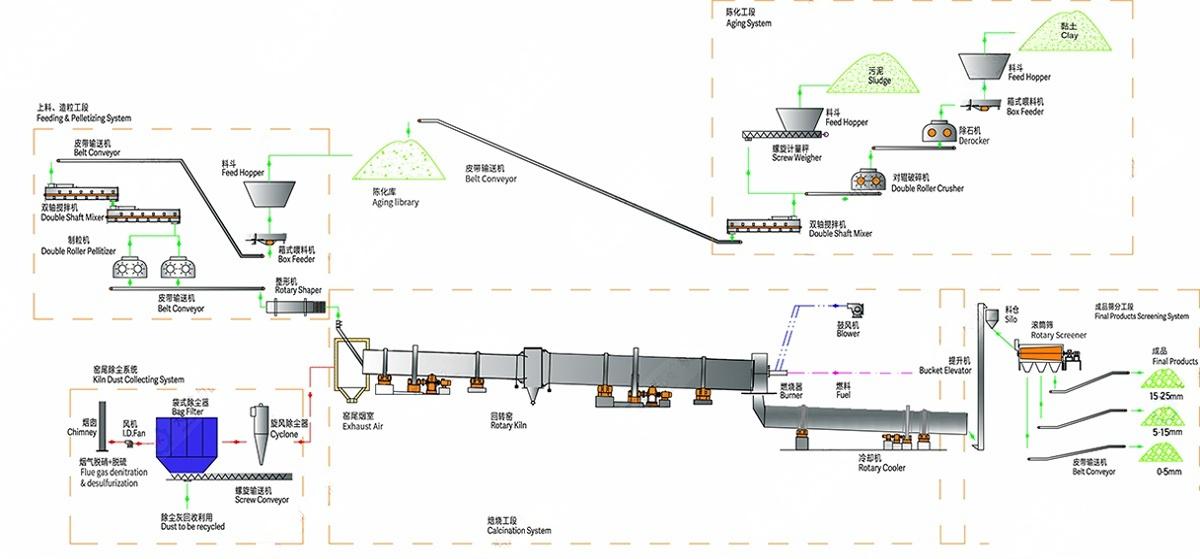

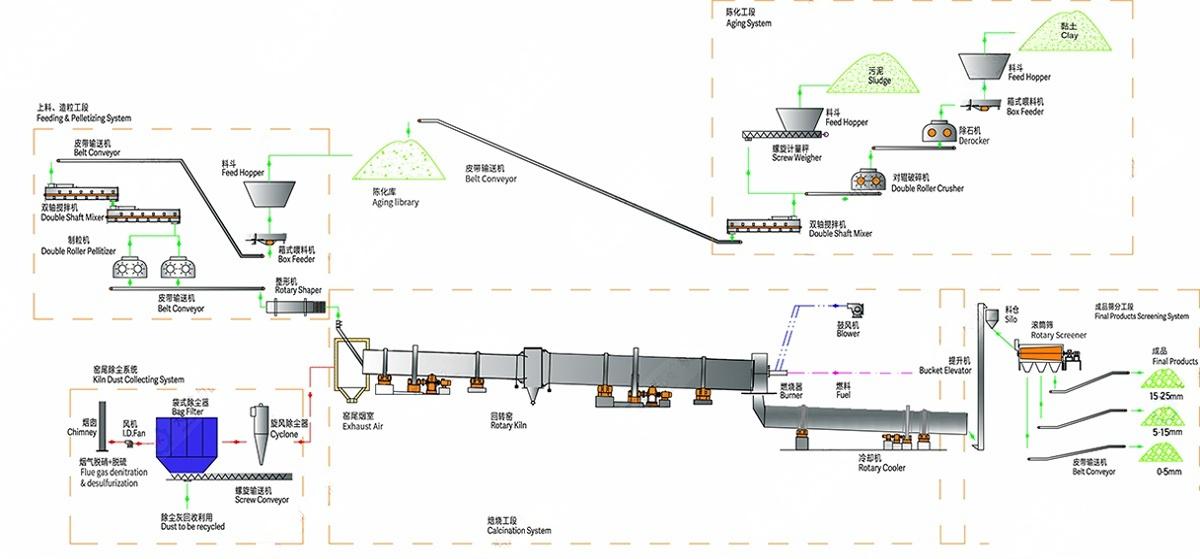

After the clay is brought into the factory by car, it is stored in the pile shed. The general storage capacity is about 30 days. The clay particle size is about 100~200mm, which is sent to the bin by the forklift, sent to the roll crusher by the box feeder under the bin, broken by the belt conveyor to the two-shaft mixer for forced mixing and mixing, so that the particle size is smaller and the composition is uniform, and then into the roller granulator for extruding granulation.

The pellet ball from the granulator is sent to the shaping screen machine by the belt conveyor. After the round treatment, the small particles are screened out, and the qualified pellet ball is sent to the double-barrel plug-in rotary kiln for preheating and roasting. After the fired ceramic products fall into the cooling machine to cool, the finished products of different particle sizes are divided by the rotary screen, respectively stored in the storage yard, bagged and shipped. The natural air cooling ceramic particles in the cooling machine is heated to form a high temperature secondary air, which enters the rotary kiln to assist combustion and save fuel. The fuel is sent to the rotary kiln by the high pressure fan through the multi-channel burner for combustion. The high temperature flue gas containing dust at the end of the kiln enters the air cooler to cool down, and then enters the bag dust collector to purify and empty.

Main equipment: ceramic rotary kiln, single barrel cooling machine, double shaft mixer, granulator, bag dust collector, belt machine, etc

Ceramide capacity: 50,000-600,000 (m³/a)

Specification: preheating kiln Φ 18 (m), Φ 1.55 x 1.25 x 1.8 x 20 (m), Φ 22 (m), 2 x 24 Φ (m), 3 x 20 Φ (m), Φ 2.5 x 12 (m)

Burning kiln specifications: Φ 1.6 x 14 (m), 1.9 x 16 Φ (m), 2.2 x 18 Φ (m), 2.5 x 20 Φ (m), 3 x 22 Φ (m)

Calcination temperature: 1100-1200℃

Clay ceramic production line process flow

| Production capacity and host equipment parameters of sludge ceramite production line |

No.

| Device name | Sludge ceramide production line scale and equipment specifications |

| 15000 m²/a | 25000 m²/a | 35000 m/a | 50000 m³/a | 100000 m³/a |

| 1 | Roll crusher | 2PGC450*500 | 2PGC450*500 | 2PGC600×750 | 2PGC600×750 | 2PGC900*900 |

| 2 | Double shaft mixer | ZJ300 | ZJ400 | ZJ500 | ZJ600 | ZJ650 |

| 3 | Roller granulator | GL600×500 | GL700*600 | GL800*700 | GL800*7002台 | GL800×7004台 |

| 4 | Plug rotary kiln | Preheating kiln Φ1.25*18m | Preheating kiln

Φ1.55-20m | Preheating kiln

Φ1.8-22m | Preheating kiln

φ2*24m | Preheating kiln

φ3*20m/φ2.5*12m |

| Roasting kiln φ1.6*14m | Calcining kiln

Φ1.9×16m | Calcining kiln

φ22*18m | Calcining kiln

①2.5*20m | Calcining kiln

φ3*22m |

| 5 | Single cylinder cooling machine | φ1.2*12m | φ1.5*15m | φ1.8×18m | φ2*20m | φ2.2*22m |

| 6 | Vertical cooler | 一 | 一 | LSF26 | LSF36 | LSF36 |

| 7 | Air cooler | 50m² | 80m² | 120m² | 200m² | 400m² |

| 8 | Bag dust collector | PPC32-3 | PPC32-5 | PPC64-4 | PPC64-5 | PPC96-5 |

| 9 | Air blower | 5633m°/h 15kW | 8294m²/h 22kW | 12213m³/h 22kW | 16099m²/h 37kW | 33309m³/h 75kW |

| 10 | Rotary screen | φ600=2900mm | φ800=3600mm | ①900*4200mm | φ1100*4500mm | φ1500*6000mm |

| 11 | Belt conveyor | More than B500 |

| The main configuration of different scale sludge ceramite production lines |

Ceramide productivity host parameters | Annual output | 15000m³/a | 25000m²/a | 35000m²/a | 50000m³/a | 100000m³/a |

| Plug-in rotary kiln | Specification | Preheating kiln | φ1.25*18m | φ1.55*20m | φ1.8*22m | φ2=24m | ①3×20m/φ2.5×12m |

| Calcining kiln | Φ1.6*14m | φ1.9×16m | φ2.2*18m | φ2.5*20m | φ3*22m |

| Output (m²/h) | 2.21-2.96 | 3.27-4.36 | 4.42-5.9 | 5.57-7.41 | 9.85-13.13 |

| Slope (%) | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 |

| Speed (r/min) | Preheating kiln | 1-5 | 1-5 | 1-5 | 1-3 | 1-5 |

| Calcining kiln | 1-5 | 1-5 | 1-5 | 1.2-3.6 | 0.9-2.7 |

| Calcination temperature (℃) | 1100-1200 |

Introduction of finished clay ceramisite production line

Clay ceramisite is made of clay with appropriate composition as raw material, and some other materials need to be added when the composition is not suitable, which is processed into granulated and expanded at high temperature in the rotary kiln.

Clay ceramite has the properties of light bulk weight, high strength, heat preservation, heat insulation, high seismic and compressive strength, environmental protection and energy saving, and strong construction adaptability.