Sugarcane beet equipment Product introduction

Beet sugar processing procedure

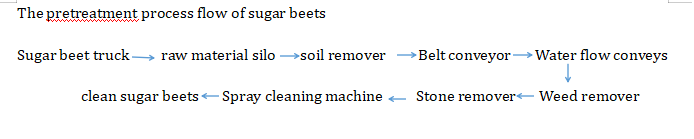

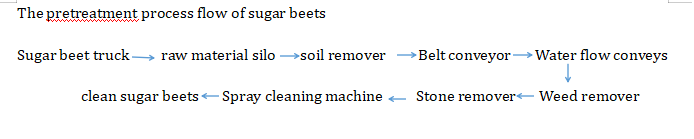

Fresh washing and slicing of beets: Remove rocks and weeds before washing beets. Then the washed beetroots are cut into thin noodles, known as beet shreds, and sent into the extraction system.

Sugar extraction: Soak in hot water to remove substances. Then heat the syrup and add lime and carbon dioxide to remove the remaining impurities.

Sugar production (purification - crystallization - drying) - Filter the purified fruit juice, evaporate and concentrate it, crystallize it and dry it. Then store it in silos until it is packaged and transported.

Sugar beet stacker

Due to the in-depth mechanization of sugar beet harvesting in recent years, while it has brought convenience, it has also carried a lot of impurities into the sugar beet piles, resulting in the actual weight of the sugar beets being insufficient after loading onto vehicles. Meanwhile, when debris enters the sugar beet stacks, it leads to the reproduction of microorganisms, causing the sugar beets to deteriorate before they even enter the production line. Sometimes, this results in the loss of tens of thousands of tons of sugar beets, causing significant economic losses to sugar factories. This device has solved the above problems very well

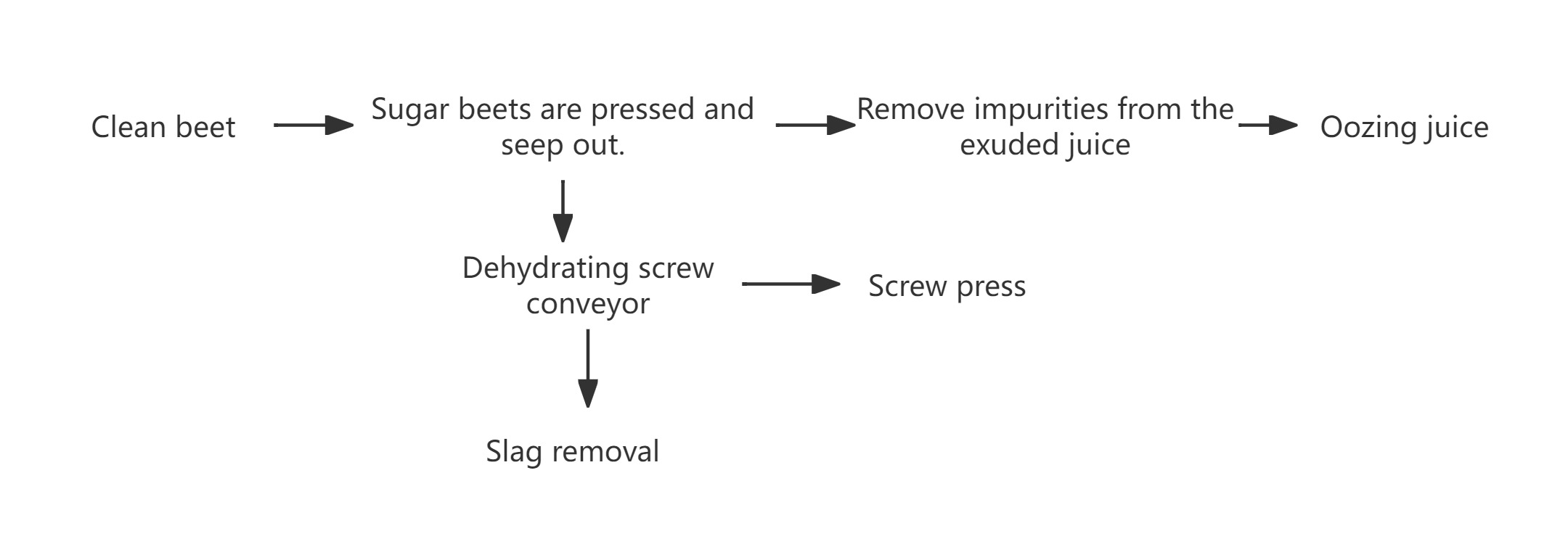

Sugar beet exudator

The sugar beet exudator is available in three specifications: 1500T/D, 2000T/D and 3000T/D, with a capacity of up to 20%. It is a horizontal continuous type (Dds type) and is the preferred equipment for sugar beet factories.

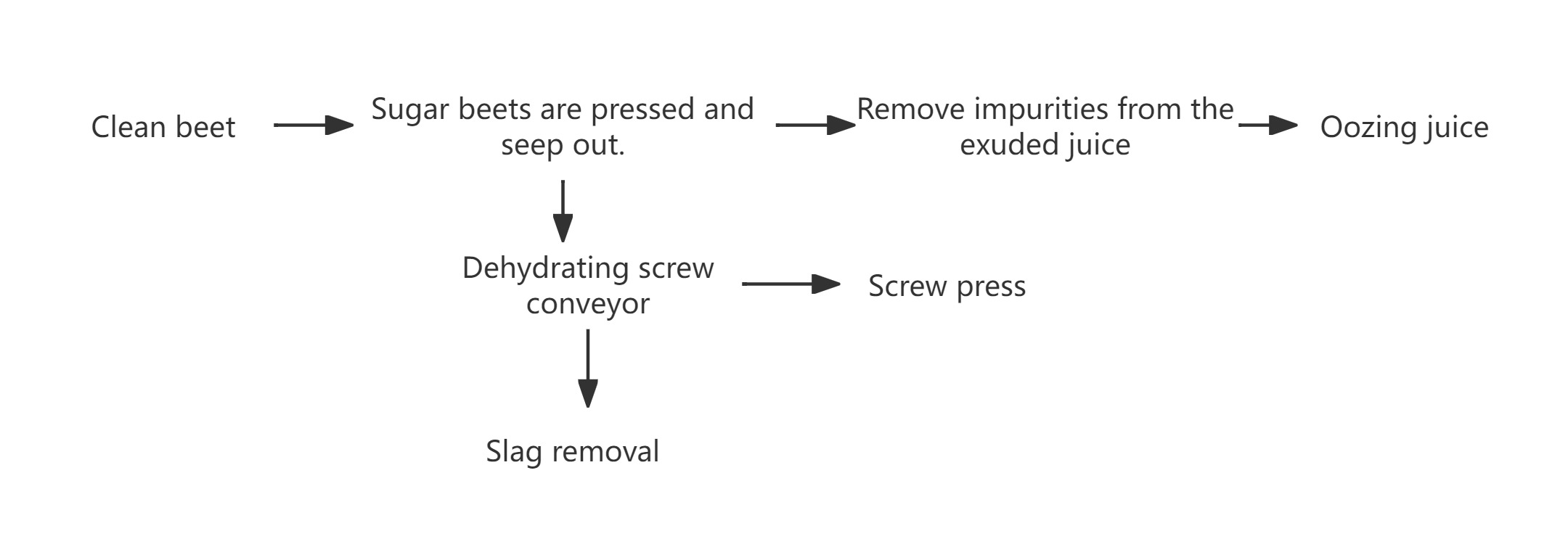

The process flow of beet slicing and seeping out

Sugar beet waste meal drum dryer system

The actual production capacity of this system can reach 4,700 tons per day. It features energy conservation and environmental protection, high evaporation efficiency, high degree of automation, large production capacity and low failure rate.

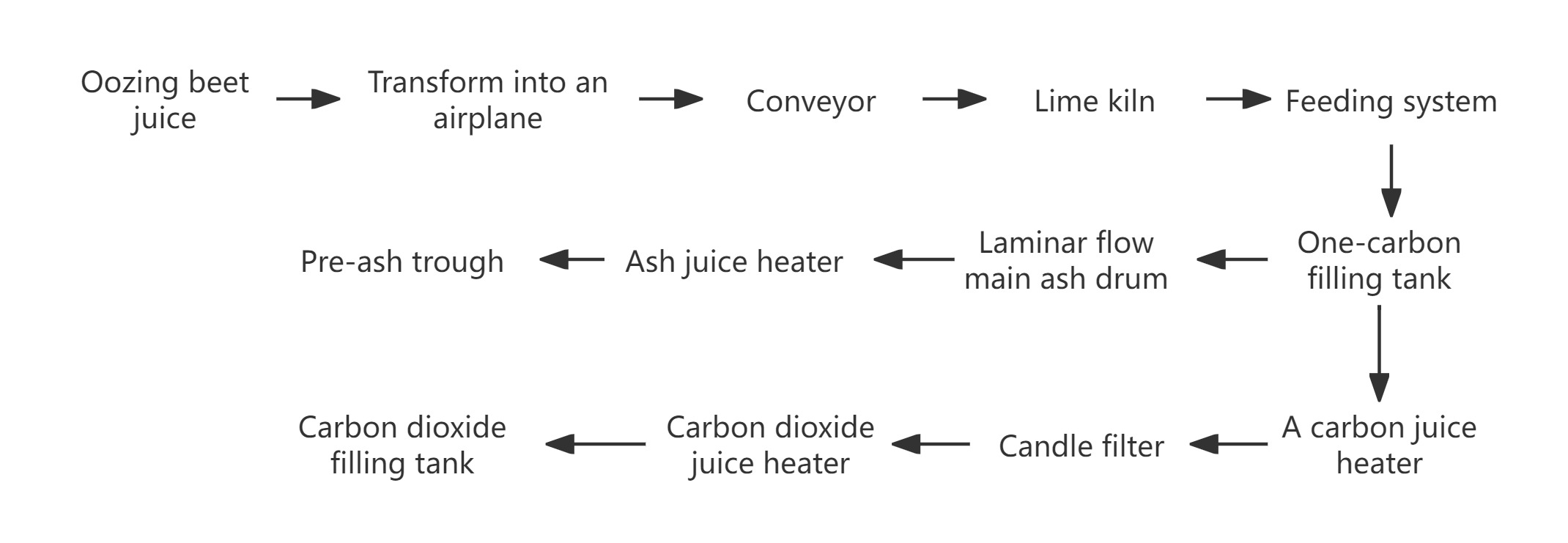

Beet closed positive pressure high-efficiency lime kiln

This lime kiln is divided into two forms: vertical feeding by the lifting cylinder and inclined bridge feeding. It adopts a double-cap kiln sealing structure with a high kiln gas content. The isobaric blower positive pressure operation ensures high calcination efficiency. The rotary distributor is used for material distribution to prevent deviation. The conical unloading aircraft continuously discharges ash, and the star-shaped discharging aircraft evenly discharges ash. It uses electronic ignition without fire eyes and PLC control for automatic feeding, which can save a lot of labor. The product is available in specifications of 120m2, 200m2, 250m2, 270m2, 350m2 and 400m2. It can also be designed according to the user's needs. Our company provides equipment and technical training.

Lime disinfection machine (chemical machine)

The lime mixing machines produced by our company include counter-flow mixing machines that meet the three-in-one standards, co-current mixing machines, and inner sleeve mixing machines. This product has a high production efficiency and is needed by sugar factories and chemical factories produced by the tansuan process. The product specifications and production capacity are φ 1500(1500t/h), φ1800(3000t/h), φ2200(4000t/h), and φ2500(6000t/h).

Internal circulation carbonated filling tank

The rationality of the structure of the filling tank is an important factor for the absorption of CO2 during the filling process. Pursuing a high absorption rate is the aspiration of all sugar factories. The carbonated filling tank produced by our company is a filling equipment with an internal circulation well and a gas scraper, which is designed based on experience. The wasi distribution is uniform, the absorption rate is good, and it can automatically clean the scale of the gas pipe. According to the user's needs, products of different specifications can be designed.

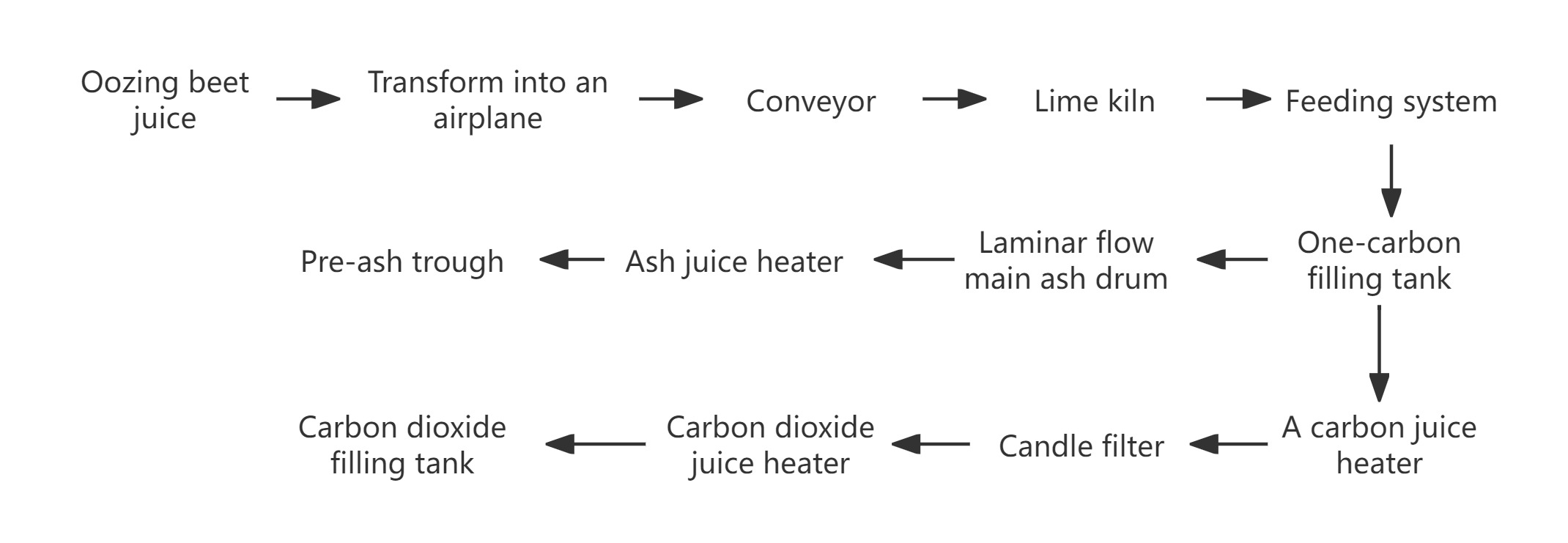

The purification process flow of bicarbonate method

Beet processing raw sugar evaporation tank system machine

The evaporation tanks produced by our company are of an internal circulation structure. Their main features are reduced bottom volume and a closed juice outlet pipe, which enables effective separation of the incoming and outgoing juices.

The evaporation tanks produced by our company come in various specifications with different heating areas, featuring a helical structure and high heat transfer efficiency. This significantly reduces the thickness of the scale, thereby lowering the thermal resistance. Meanwhile, some components are made of teshu material, which increases the service life. Coupled with the structural improvement, the retention time of the sugar water is reduced. The production capacity of the evaporation tanks produced by our company is da, the sugar loss is di, the increase in sugar water pigment is shao, and the tank cleaning cycle is chang. The specifications are 550m2, 750m2, 1000m2, 1200m2, 1400m2, 1600m2, 1800m2, 2000m2, 2200m2, 2500m2, 3000m2, 3500m2, 4000m2 and 5000m2.

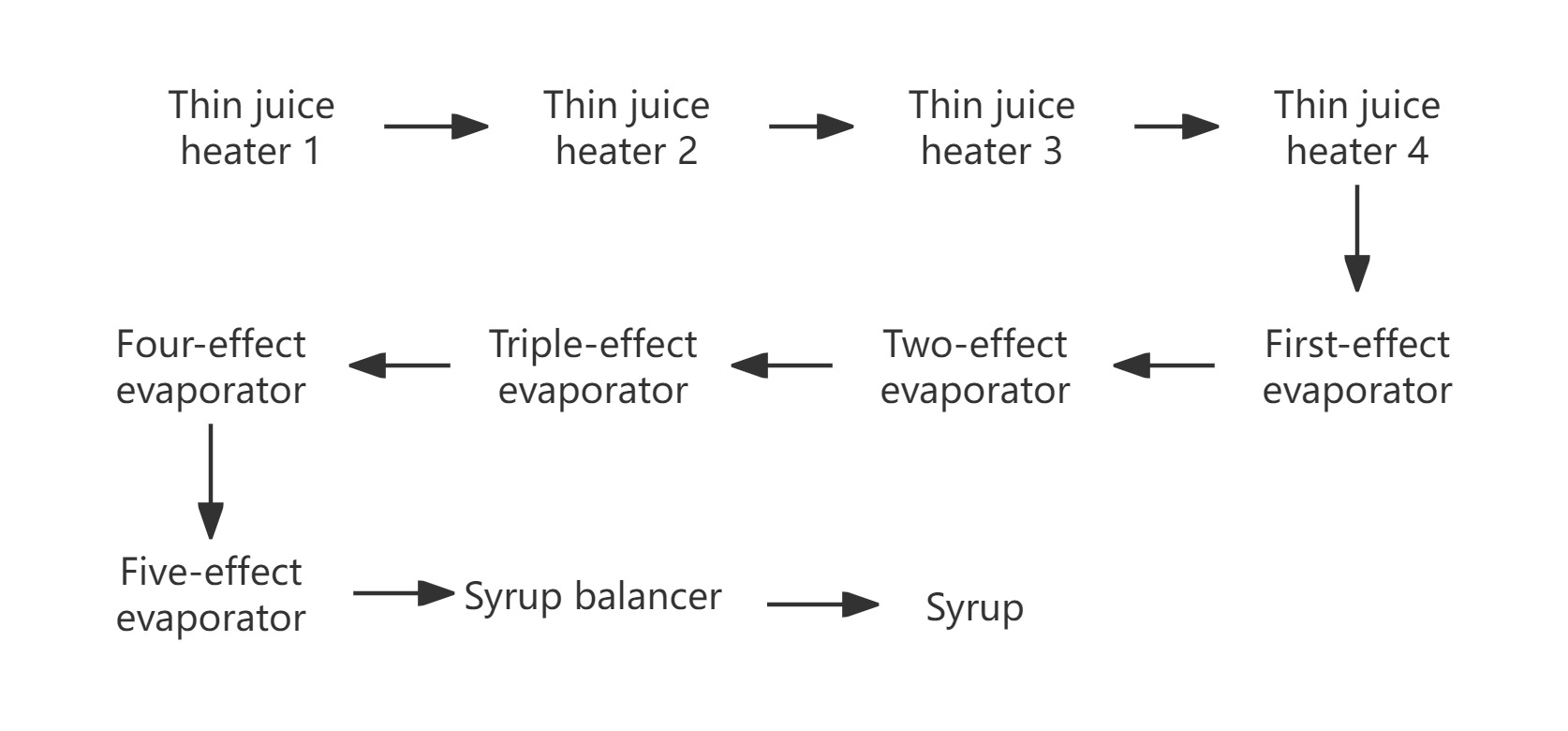

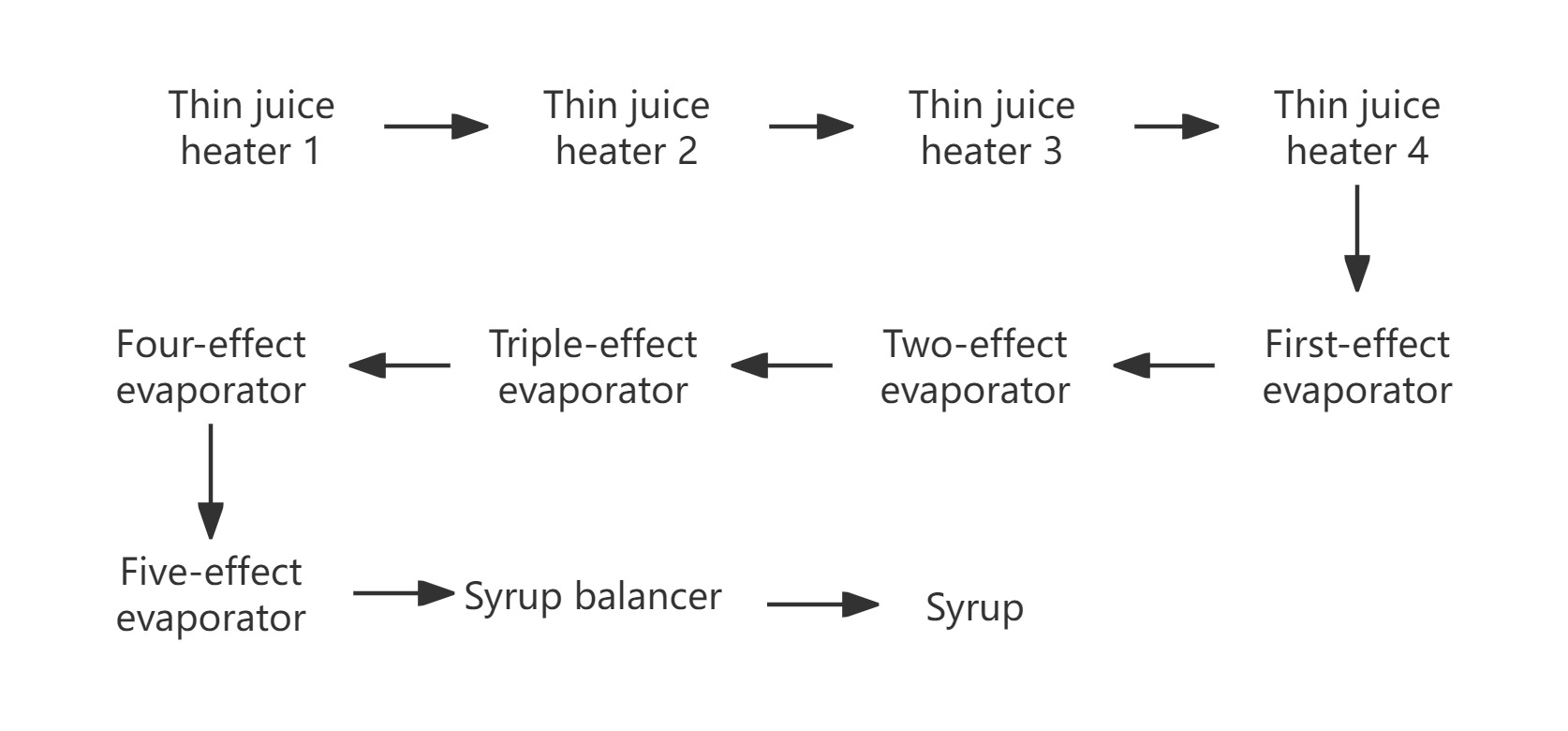

Evaporation system process flow

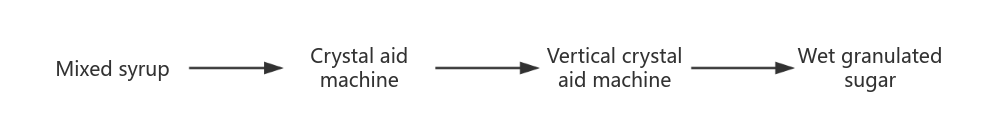

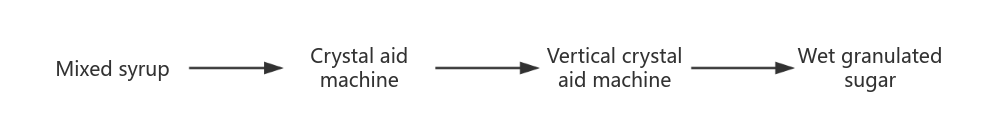

Vertical crystal aid machine

This equipment adopts hydraulic transmission, featuring low mechanical wear, few malfunctions, low noise and the characteristic of occupying a small area. The specifications are 80m3, 100m3, 150m3, 200m3 and 400m3.

Vertical continuous crystallization tank

This equipment uses the most efficient steam for sugar boiling and is equipped with an automatic control device. The operation process is safe and reliable, with a high degree of automation and simple and convenient operation. It is an energy-saving and consumption-reducing device in the sugar industry. The vertical continuous crystallization tank features a compact design structure, a reasonable overall layout and a small installation floor area.

Horizontal crystal aid machine

This equipment is designed based on the structure of the end plates and bearing housing, featuring a simple structure, convenient maintenance, good coaxiality, and smooth rotation of the stirring shaft. tebie is a special sealing form of the lubrication part, providing quality assurance for refined sugar production. The specifications are 20m3, 30m3, 40m3, 45m3, 55m3 and 60m3.

Horizontal continuous crystallization tank

The horizontal continuous crystallization tank produced by our company features excellent sugar paste circulation, improved thermal energy utilization, reduced equipment investment, simple and convenient operation, and creates favorable conditions for the continuous and automated sugar production.

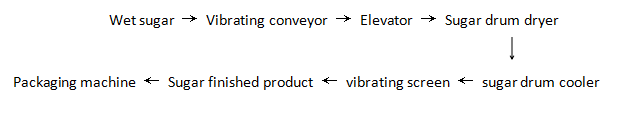

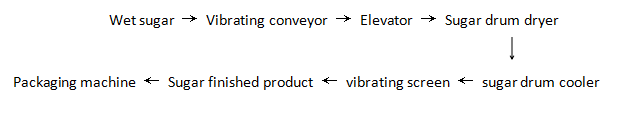

Drum dryer machine cooler

Our company produces two types of drum dryers: sugar dryers and cotton sugar dryers. The structures include integrated drying and cooling machines and split machines. The product specifications can meet the needs of sugar factories of all scales. The specifications and production capacity are 1600 (15T/H), 1800 (20T/H), 2200 (30T/H), 2500 (40T/H), 2750 (50T/H), and 3200 (70T/H). Our company can provide a complete set of process equipment including air filtration, air heating, air cooling and air dehumidification

Integrated drying and cooling machine for refined sugar

Our company's integrated sugar drying and cooling machine can provide the selection and matching of a complete set of processes including air filtration, heating, cooling and dehumidification. The specifications are 20T/H, 30T /H, 40T /H and 50T /H.