What is EVOH?

EVOH resin is a high-resistant ethylene-alcohol alcohol cluster. Its oxygen is 10,000 times that of similar products of similar products. Due to its good blocking,

forming and environmental protection characteristics, the application is very wide, including high -end new materials such as automotive fuel tanks, film, food

containers and ground heating pipes.

Especially for food packaging, it can extend the food preservation and incense period for several months or even years under the condition of non -preservatives.

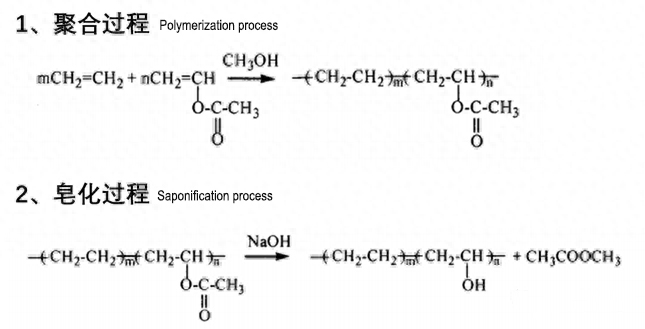

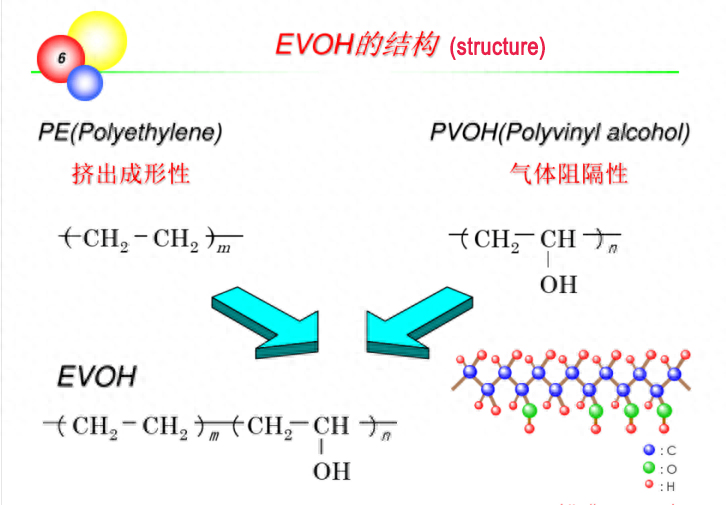

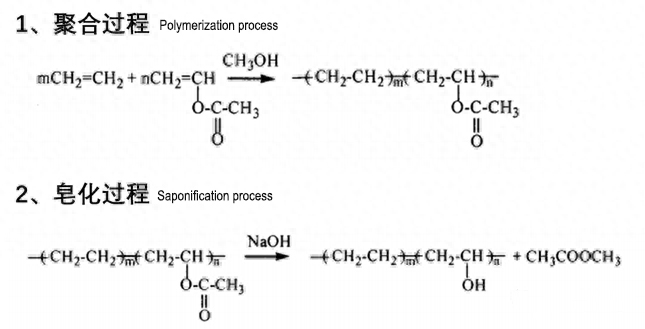

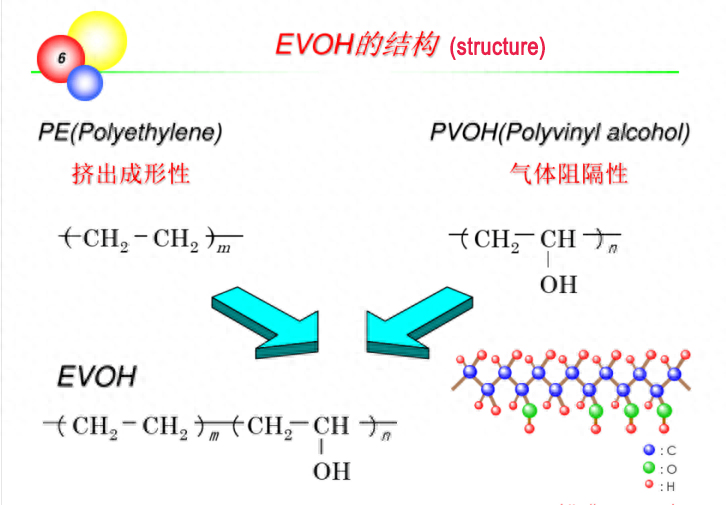

The ethylene-ethylene-ethylene alcohol cluster (EVOH) is obtained by polyvinol and ethylene, and the general ethylene content is 25%to 45%.

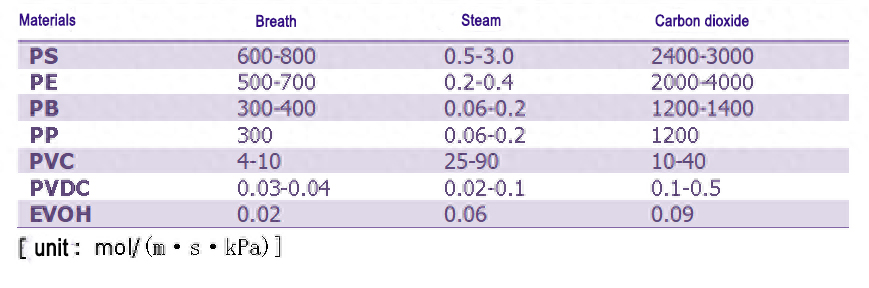

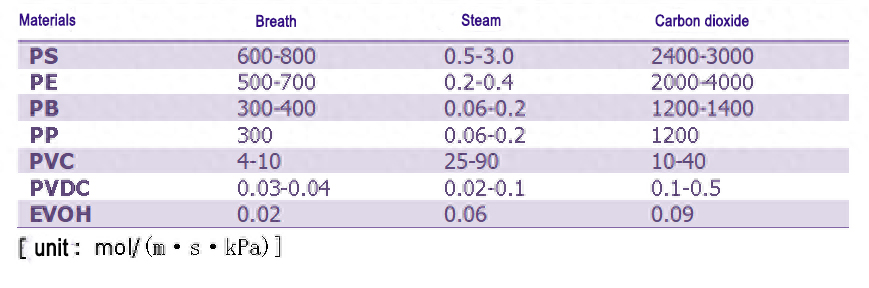

Ethylene-ethylene glycol cluster (EVOH) and polarizing daethel (PVDC) and polyacrylene (PAN) are currently the world's three most recognized high-resistance materials.

What are the properties of EVOH?

High barrier property

EVOH can effectively prevent the penetration of gases such as oxygen and carbon dioxide.

In addition, EVOH also has excellent barrier properties to non-polar oils and organic solvents.

Hygroscopic property

Due to the hydroxyl group contained in EVOH molecule, it has strong hydrophilic and hygroscopic properties. After the moisture absorption of EVOH, its barrier property will decrease.

Mechanical property

EVOH has good strength, elastic modulus and torsional properties, and has certain mechanical strength. At low temperature, EVOH is hard, brittle and has poor impact resistance.

In the application, EVOH is generally blended with other substances to modify it to solve the shortcomings of poor impact resistance at low temperature, and improve its bending fatigue resistance, impact resistance, tensile properties, etc.

Weather resistance, anti-aging

EVOH has excellent aging resistance and weather resistance, and its transparency, gloss, mechanical properties, and barrier properties change little when used for a long time.

What are the application areas of EVOH?

package

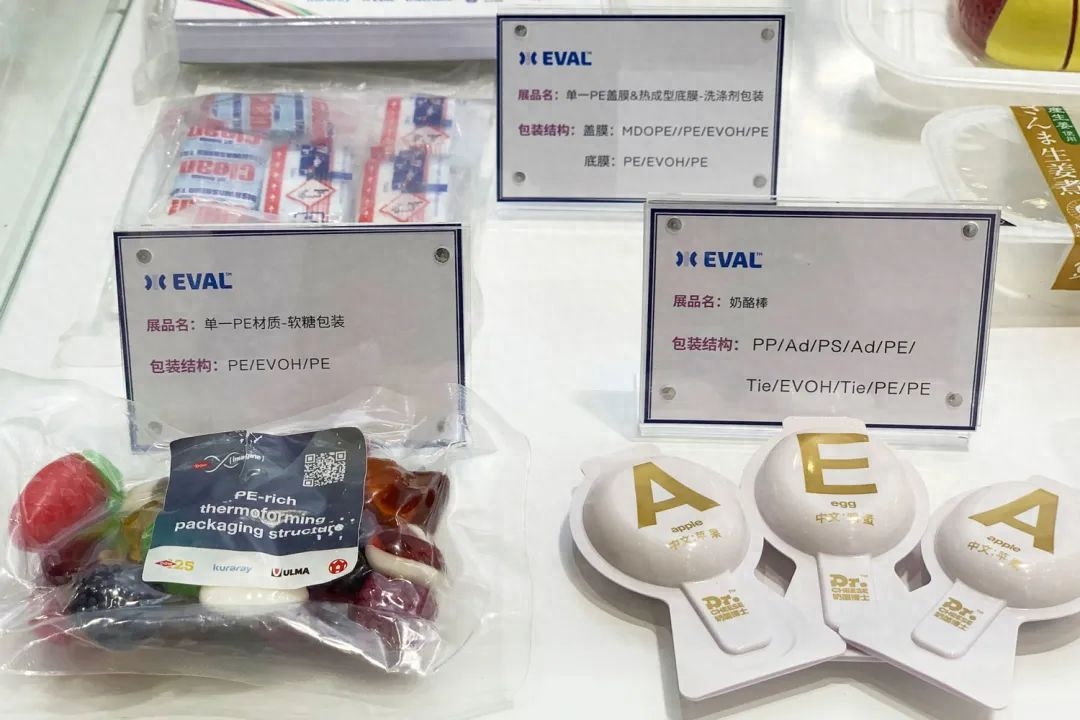

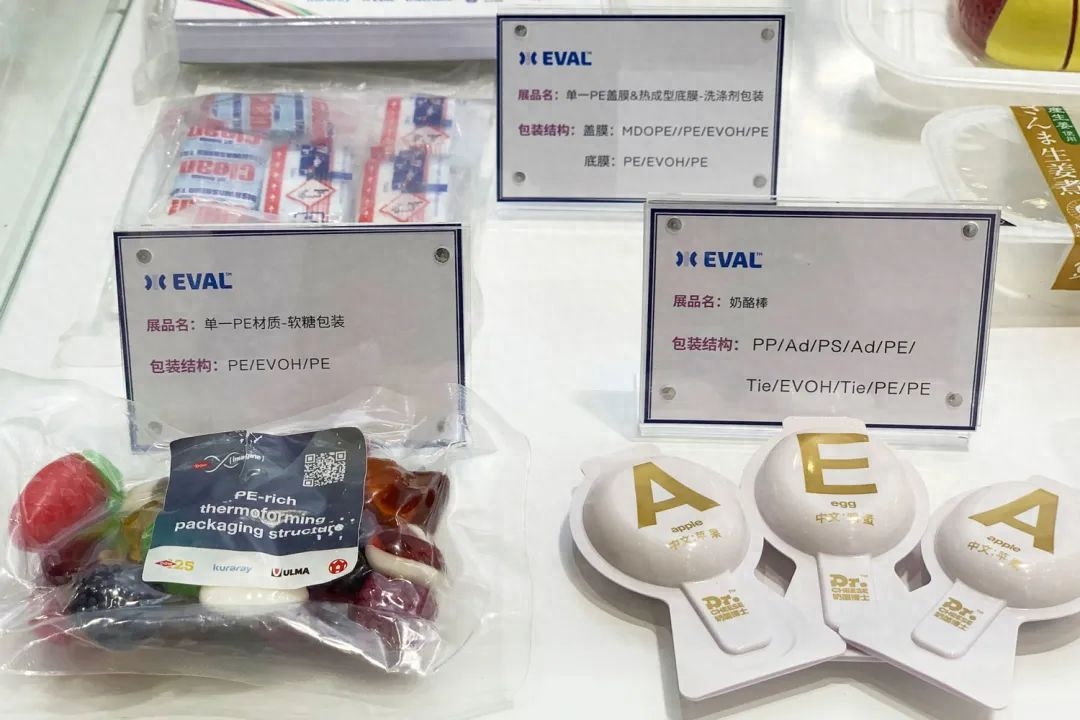

As a high barrier material, EVOH is often extruded with a variety of resins in multiple layers, which is used in the packaging of beverages, dairy products, juices, beverages, and various foods. Many Chinese aquatic companies export seafood using PE/EVOH/PA/EVOH/PE five-layer co-extrusion film vacuum packaging.

·Single PE material - Fudge packaging. Package structure: PE/EVOH/PE.

EVOH resin can also be used in non-food packaging, such as chemicals, solvents, cosmetics, health care, medicine and electronic products.

·Composite sheets were co-extruded with EVOH. Material structure: PE/Tie/EVOH/Tie/PE. Used in toothpaste, cosmetics, medicine, food market

CARS

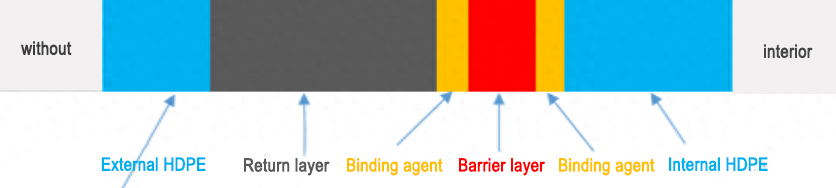

EVOH resin is blended with high density polyethylene (HDPE) to make automotive fuel tanks. HDPE/EVOH tanks are lighter and more economical than conventional metal tanks.

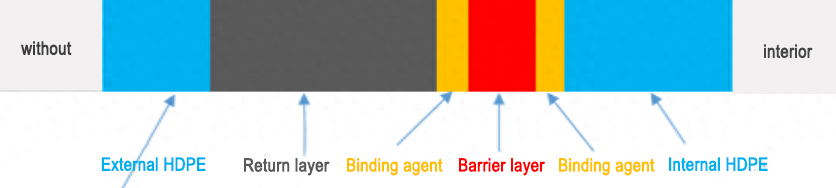

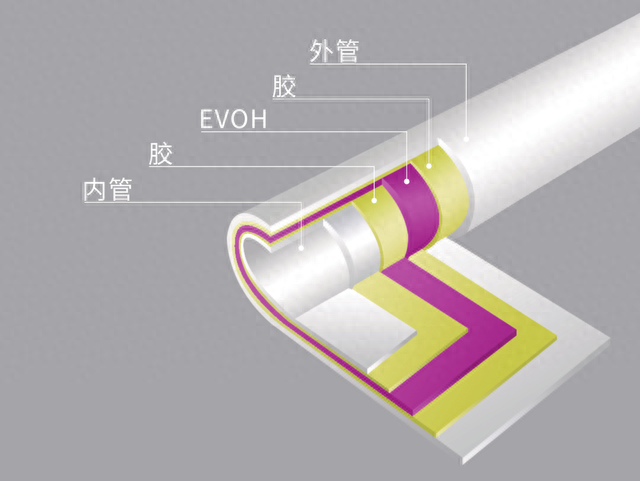

The multi-layer plastic fuel tank material structure from the outside to the inside can be divided into: new material layer (HDPE), return material layer, bond layer (LLDPE), barrier layer (EVOH), bond layer (LLDPE), new material layer (HDPE).

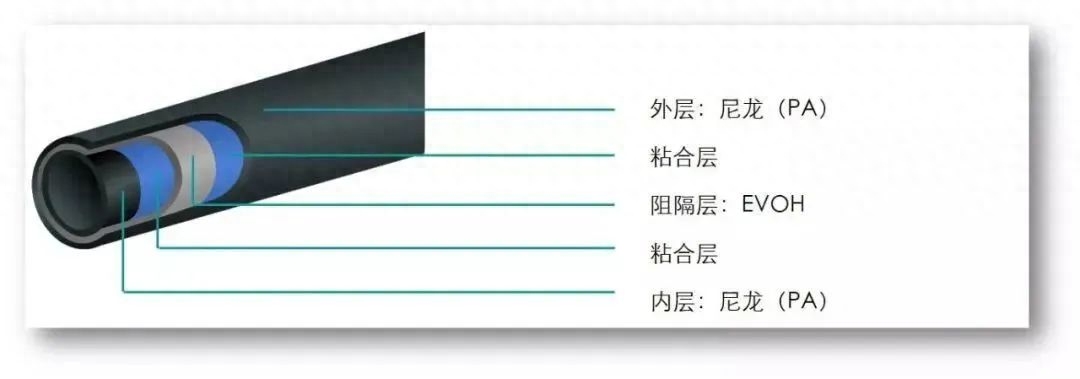

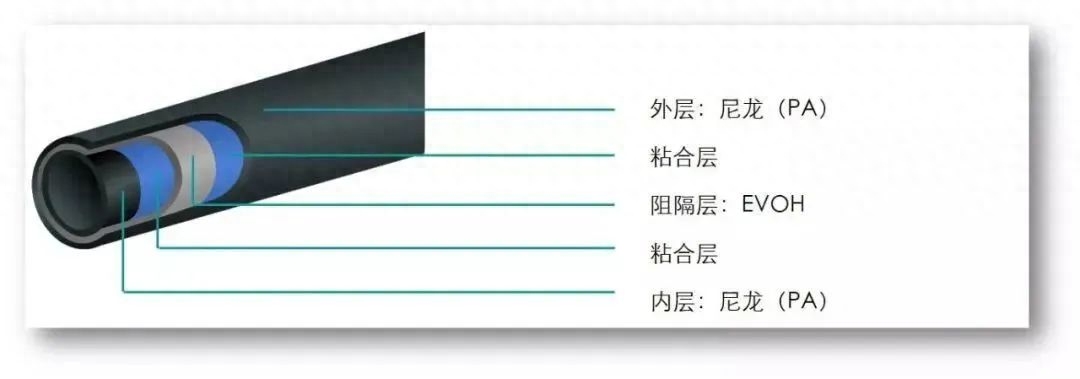

EVOH will also be used to make oil pipes for cars. PA-EVOH composite pipe density is low, can replace metal pipe, to achieve the goal of automotive lightweight, is the ideal choice for automotive oil system.

Medical treatment

EVOH resin can be used to make medical selective permeable membranes, which can be sterilized by radiation treatment. For example ↓

The hollow fiber of EVOH resin was sealed in polyethylene film and irradiated with Co60, which could be used for urine dialysis.

Hollow fiber membrane is prepared for hemodialysis, plasma grading and artificial kidney.

The temporary orthopaedic substitute and tissue repair agent were made by blending corn starch or acetate fiber with EVOH.

The drug slow release material was prepared by coating EVOH substrate on polymer material with different diffusivity.

unit

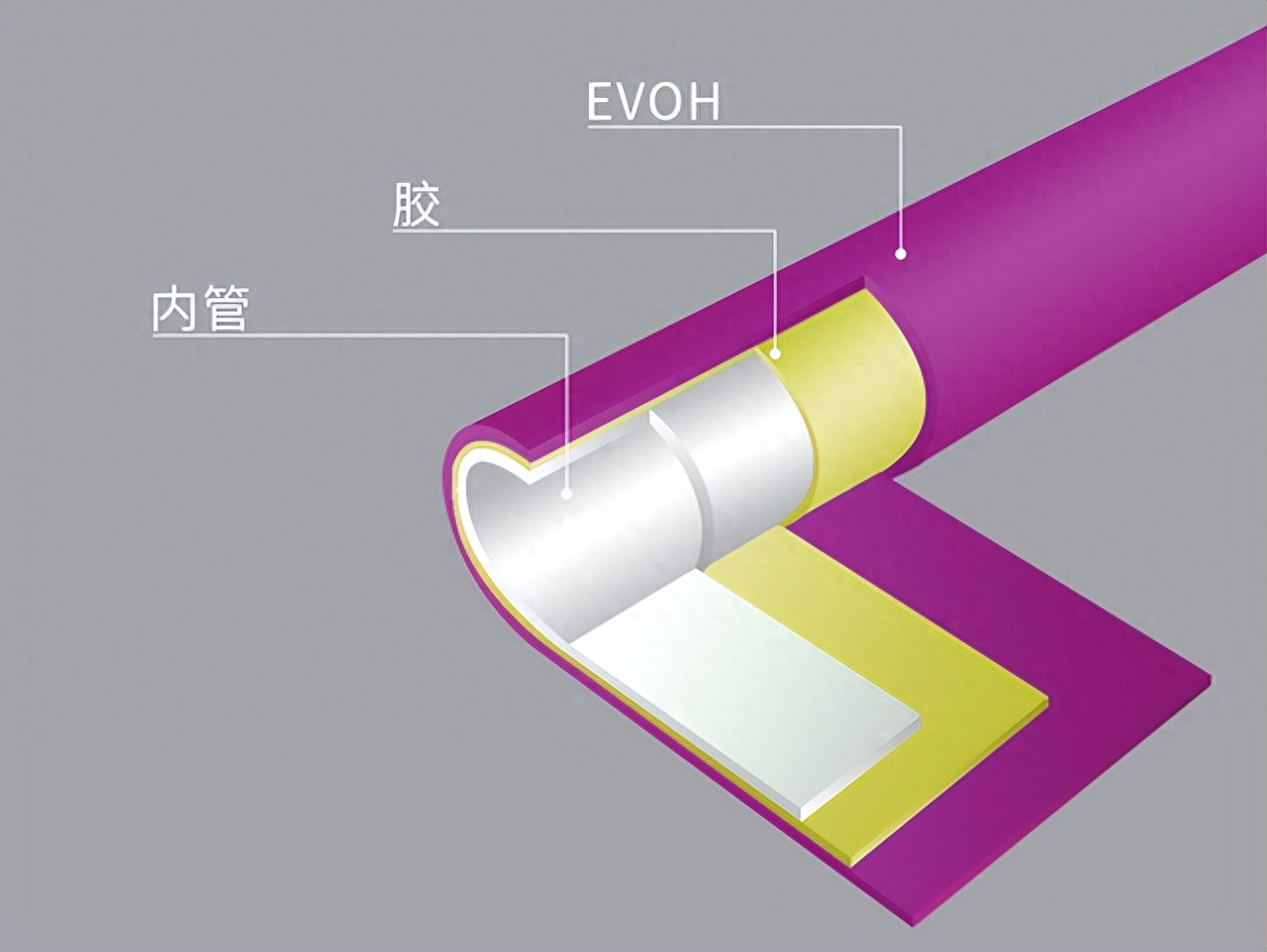

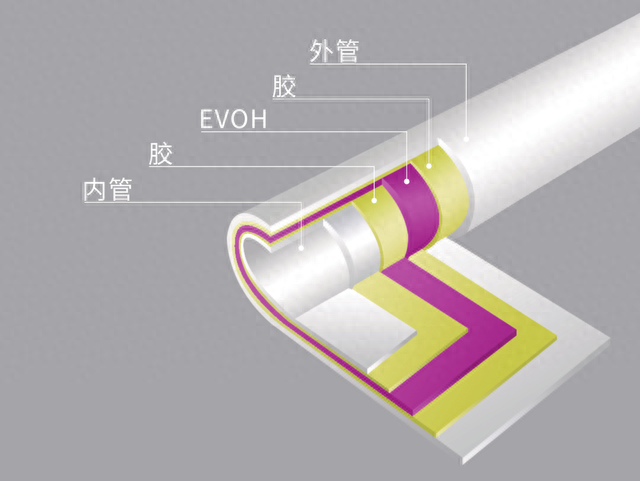

EVOH has excellent weather resistance and gas resistance, and can be used as a heating pipe material in buildings.

The EVOH oxygen blocking tube can block oxygen from penetrating into the pipeline system, thereby preventing corrosion and rust in the metal part of the heating system, and greatly extending the service life of metal parts such as metal valves, switches, boilers, and water diverters in the entire heating system.

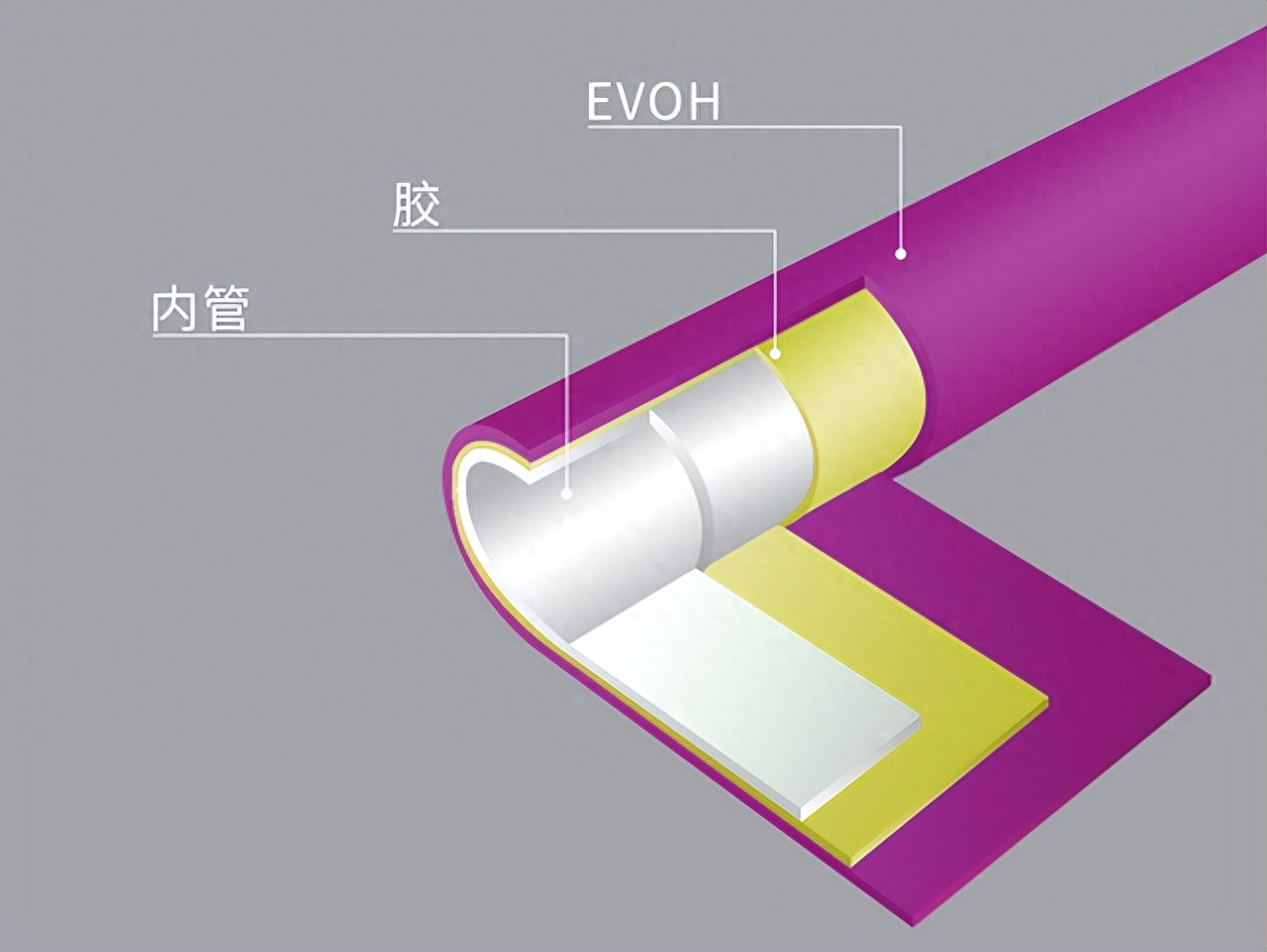

At present, there are two kinds of oxygen blocking tubes on the market, three layers of oxygen blocking tubes (external oxygen blocking tubes) and five layers of oxygen blocking tubes (internal oxygen blocking tubes), all of which use EVOH as the oxygen blocking layer.

Other

EVOH resin can also be seen on the hot melt bonding and coating of various fiber fabrics. Because it has superior bonding properties and washable resistance to fibers, it is especially suitable for garment processing and manufacturing.

By adding EVOH, the hydrogen storage tank is elastic even at low temperatures, ensuring excellent barrier properties.

Sinopec Chuanwei brand, ethylene - vinyl alcohol copolymerization resin EW series products are thermoplastic high barrier resin developed by Chuanwei Chemical's own technology, with good high barrier property, transparency, molding processability, is one of the ideal raw materials for packaging materials, automotive fuel tanks, pipeline materials. The oxygen barrier performance of the product is 10,000 times that of LDPE.