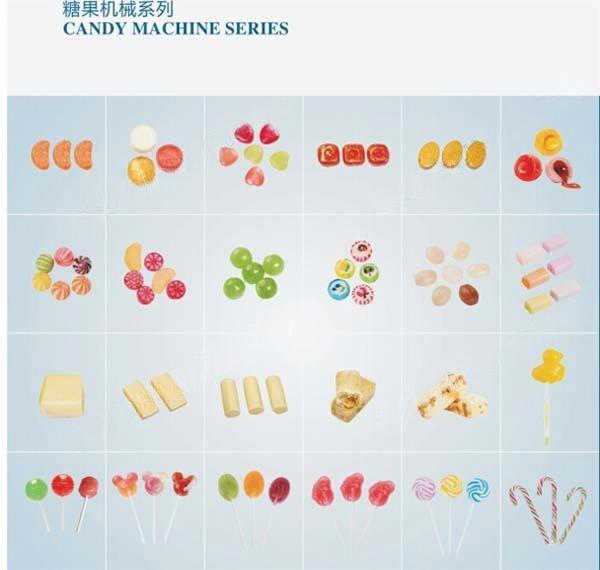

Candy and biscuit equipment Product introduction

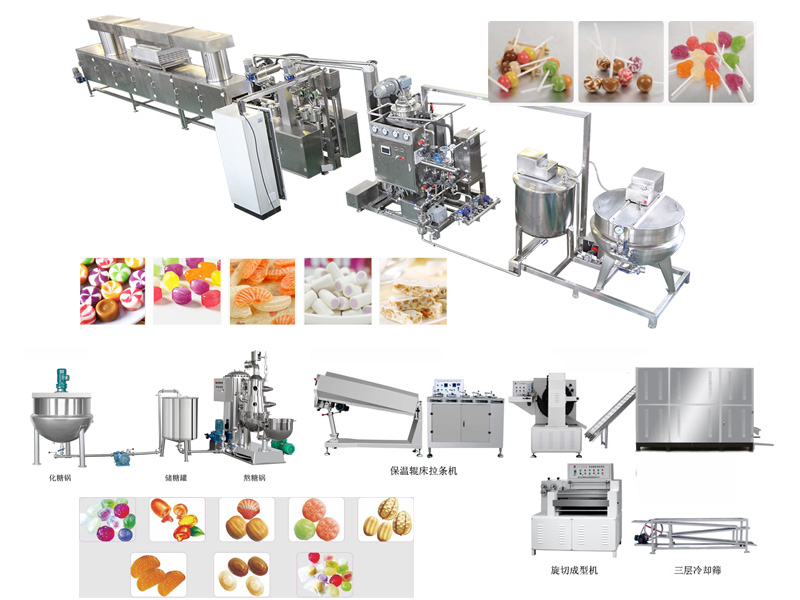

Hard candy production line equipment is divided into casting hard candy production lines, stamping hard candy production lines, and extrusion hard candy production lines. It includes cream-flavored filled hard candy production equipment, casting fruit-flavored gel hard candy processing machinery, stamping refreshing hard candy production machinery and other candy production line equipment

1.Casting hard candy production line

Fully automatic PLC-controlled hard candy casting production line

Model ZY1200- Casting Hard Candy Production Line

Model ZY600- Casting hard Candy Production Line

Model ZY450- Casting Hard Candy Production Line

Model ZY300- Casting Hard Candy Production Line

Model ZY150- Casting Hard Candy Production Line

Fully automatic servo-controlled hard candy casting production line

Model ZY1200-S servo casting hard candy production line

Model ZY600-S servo casting hard candy production line

Model ZY450-S servo casting hard candy production line

Model ZY300-S servo casting hard candy production line

Model ZY150-S servo casting hard candy production line

2. Fully automatic hard candy die stamping production line

Sandwich hard candy production line

Cylindrical and spherical hard candy production lines

Spherical lollipop production line

Special-shaped lollipop production line

Wavy candy/cane candy production line

Nougat/Block milk candy production line

Milk candy production line

Sandwich milk candy production line

Cylindrical milk candy production line

Large cylindrical milk candy production line

3. Extruded hard candy production line

Xylitol chewing gum production line

Irregular-shaped milk candy bubble gum production line

Milk candy bubble gum production line

Tablet sugar production line

Chocolate forming production line

Chocolate bean production line

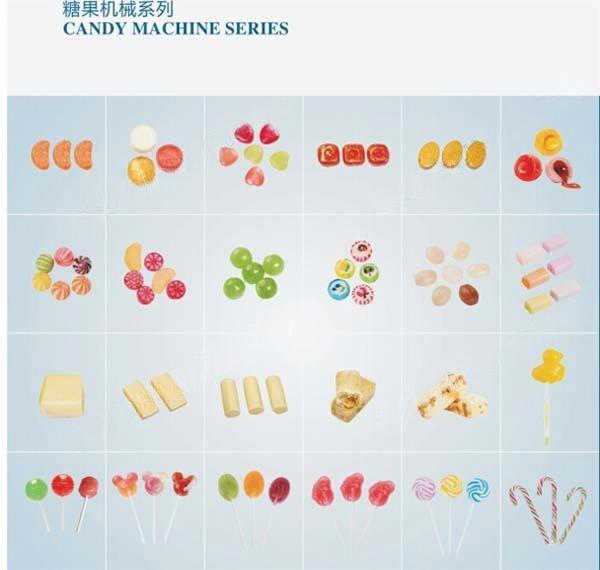

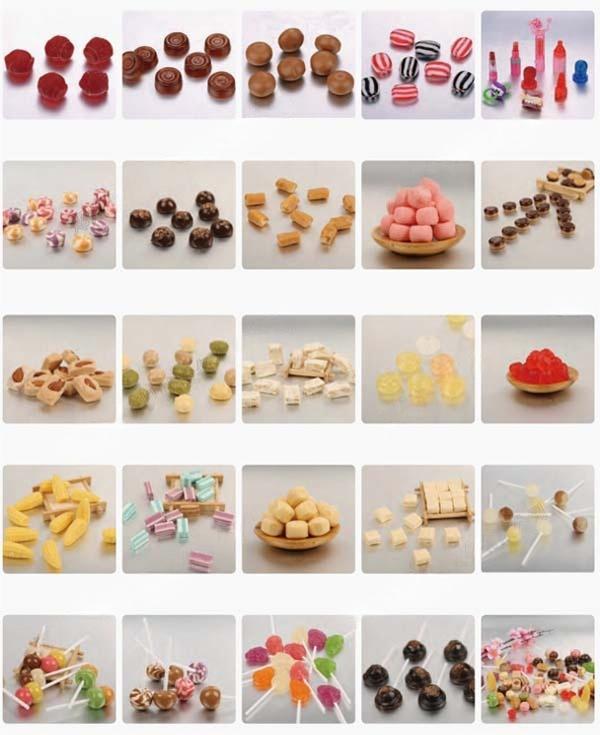

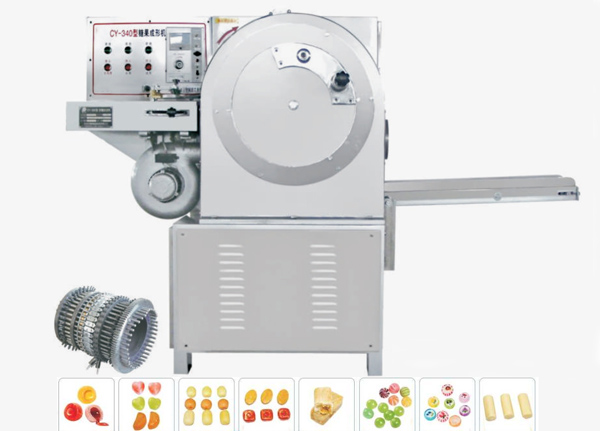

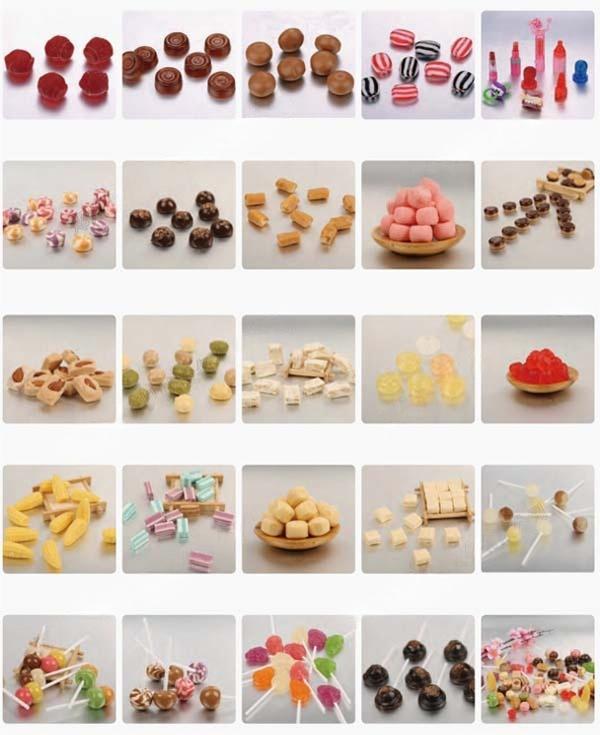

4. Types (Shapes) and applications of hard candies

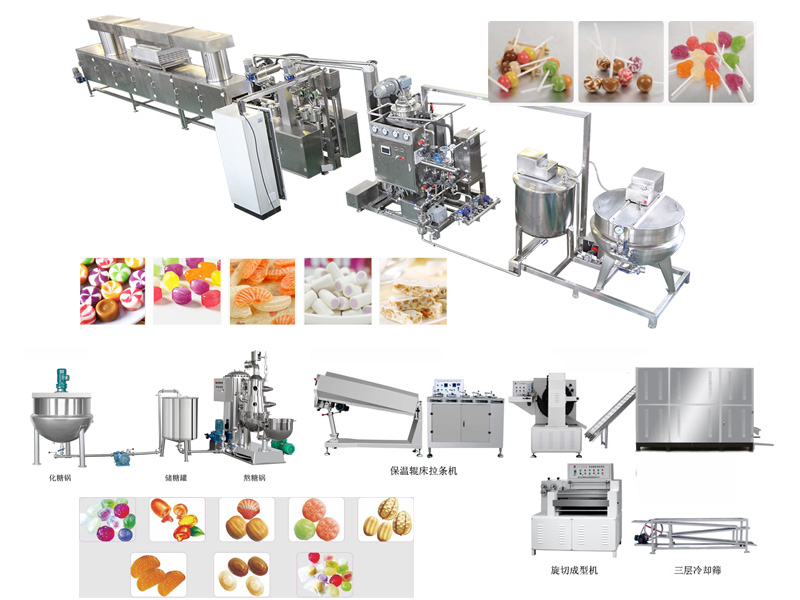

5. Working Principle of Hard Candy Machine

6. Installation of the hard candy production line

7. Sales and prices of hard candy production lines

Casting hard candy production line

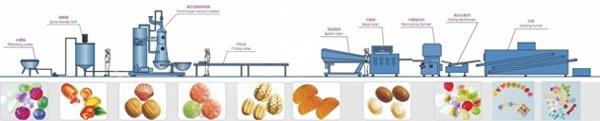

The hard candy casting production line is a continuous vacuum film hard candy production line. This equipment integrates mechanical, electrical and control systems, featuring easy operation, compact structure and high degree of automation. The continuous vacuum film casting production line can not only produce transparent crystal candies, two-color candies, double-layer and double-flavor candies, and filled candies, but also produce spiral-shaped spray-flower candies and other colorful and multi-flavored candies.

- Sanitary structure design and manufacturing, meeting GMP production requirements;

- The vacuum sugar boiling temperature, time, pouring temperature and pouring speed are automatically programmed and controlled by PLC.

- The LED touch screen displays the process flow, which is easy to operate.

- Complete the quantitative injection and mixing of flavorings, pigments and acid solutions online;

- The conveyor chain belt, cooling system and double demolding mechanism ensure demolding.

- Candies of various shapes can be produced according to different molds.

- The optional chocolate quantitative filling system can produce chocolate core candies.

- The production capacity of the series of products can range from 50 kilograms per hour to 1,200 kilograms per hour.

- Variable frequency speed regulation controls the flow of sugar liquid, ensuring accurate flow and stable quality of sugar paste.

- The dynamic mixer completes the quantitative addition and mixing of essence, pigment and acid solution online.

- By replacing some devices and molds, this production line can produce spherical, flat and three-dimensional rods

- The process flow of the hard sugar casting production line: sugar dissolving - conveying, filtering, temporary storage, quantitative conveying, syrup - preheating, film vacuum boiling, unloading, online mixing of flavoring, pigment and sugar paste - content - casting - cooling - demolding - conveying - packaging - finished product

Some main equipment

Some main equipment

Vacuum continuous boiling machine

- Main components: Syrup pump, heater, syrup inlet, secondary steam discharge system, needle valve, vacuum steam chamber, unloading control system, rotary pot, vacuum system

It features automatic sugar boiling and automatic temperature control functions. The sugar boiling speed is fast, and the syrup produced has high transparency.

Working principle:

The purpose of boiling sugar is to remove most of the water in the sugar solution after dissolving sugar, so that the sugar paste can reach a very high concentration and retain less water. To turn the sugar solution into a thick sugar paste, the increase in concentration must be achieved through a boiling and evaporation process with an increasing temperature gradient. This process is achieved through continuous boiling and processing, thus it is called boiling sugar. The water in the sugar liquid needs to escape from the liquid surface and enter the space to be discharged. The faster the escape speed, the faster the boiling speed. Under vacuum conditions, sugar solution can boil and evaporate at a relatively low temperature, with a fast evaporation rate and good product quality. Operating procedures: The vacuum sugar boiling process is generally divided into three stages: preheating, evaporation and vacuum concentration. The preheating stage is to increase the temperature and concentration of the sugar solution and shorten the cycle of vacuum sugar boiling. During the evaporation stage, the remaining water in the sugar solution is removed.

Sugar boiling equipment is actually a set of evaporation and concentration equipment. The function of the heater is to provide an appropriate heat source and sufficient heat transfer area to heat the sugar liquid to the boiling state. The evaporator enables the sugar solution to quickly remove water in a boiling state, and the transfer pump stably transcribe the sugar solution throughout the entire process to achieve continuous and balanced production.

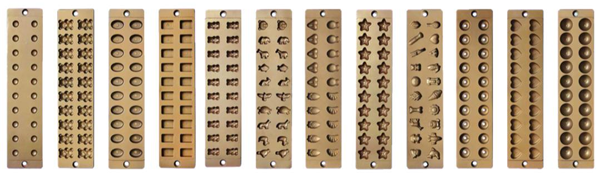

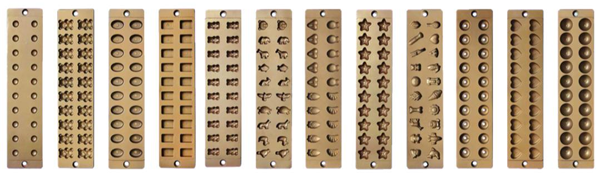

Mold

Customers can put forward their own design concepts, and we will complete the mold drawings. During the operation of the machine, just by changing different molds, candies of different shapes can be produced.

Casting mold forming machine

Main components: conveyor belt, model tray, sugar injection nozzle, sugar pouring pump, storage tank, cooling device.

This machine is controlled by a PLC system, and parameters such as temperature and pouring speed can all be controlled on the touch screen. Meanwhile, variable frequency speed regulation is adopted to control the accurate flow rate of the sugar liquid, ensuring the stability of the sugar paste quality.

Casting mold forming can produce hard candies, soft candies and soft candies. It has a wide range of applications and the equipment required is roughly the same. During the mold casting process, when the boiled sugar paste is still in a flowing state, the liquid sugar paste is quantitatively injected into the continuously running model tray, then rapidly cooled and shaped. After that, it is separated from the model tray and sent to the packaging machine along the conveyor belt for packaging.

Working principle: The function of the sugar pump is to push the sugar paste into the sugar injection nozzle. It is composed of two cylinders assembled together. The outer cylinder is a fixed cylinder, with a tank channel on the side that is connected to the storage trough, and a small hole at the bottom that is connected to the sugar injection nozzle. The inner cylinder is an opening and closing cylinder. There is a connecting handle in the middle of the inner and outer periphery of the cylinder, which is connected to the lever that swings left and right. There is a small hole on the side and a small hole at the bottom of the cylinder. When swinging, the small hole at the bottom closes with the small hole at the bottom of the outer cylinder, and the small hole on the side connects with the channel of the storage trough. When the small hole on the side closes with the empty opening on the side of the outer cylinder, the sugar filling nozzle of the wine barrel is connected with the small hole at the bottom. Inside the opening and closing cylinder, there is a piston. When the piston moves up and down, it can draw in air and press the sugar paste against the sugar injection nozzle. The size of the piston's movement distance determines the amount of sugar paste discharged. The piston's movement distance can be adjusted according to the size of the sugar block. At the bottom of each sugar pump, there is a sugar injection nozzle, which equates the number of sugar models.

Fully automatic PLC-controlled hard candy casting production line

Model ZY1200- Casting Hard Candy Production Line

Output :1200kg/h

Candy weight: According to the size specified by the customer

Pouring speed :55-65n/min

Steam demand :650kg/h,0.5-0.8MPa

Compressed air demand :0.45m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%.

Overall power :48kw/380v

The overall length of the machine is 22 meters

Total weight of the whole machine: 7,500 kg

Model ZY600- Casting hard Candy Production Line

Output :600kg/h

Candy weight: According to the size specified by the customer

Pouring speed :55-65n/min

Steam requirement :500kg/h,0.5-0.8MPa

Compressed air demand :0.3m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%.

Overall power :40kw/380v

The overall length of the machine is 20m

Total weight of the whole machine :5000kg

Model ZY450- Casting Hard Candy Production Line

Output :450kg/h

Candy weight: According to the size specified by the customer

Pouring speed :55-65n/min

Steam demand :400kg/h,0.5-0.8MPa

Compressed air demand :0.25m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%.

The overall length of the machine is 17 meters

Total weight of the whole machine: 4,500 kg

Model ZY300- Casting Hard Candy Production Line

Output :300kg/h

Candy weight: According to the size specified by the customer

Pouring speed :55-65n/min

Steam requirement :300kg/h,0.5-0.8MPa

Compressed air demand :0.2m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%

Overall power :27kw/380v

The overall length of the machine is 17 meters

Total weight of the whole machine :4000kg

Model ZY150- Casting Hard Candy Production Line

Output :150kg/h

Candy weight: According to the size specified by the customer

Pouring speed :55-65n/min

Steam demand :250kg/h,0.5-0.8MPa

Compressed air demand :0.2m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%

Overall power :18kw/380v

The overall length of the machine is 15 meters

Total weight of the whole machine: 3,500 kg

The process flow of the hard candy casting production line

Sugar dissolving - conveying - filtering - temporary storage - Quantitative conveying of syrup - preheating film vacuum boiling and unloading, online mixing of flavoring, pigment and sugar paste - content - pouring - cooling - demolding - conveying - packaging - finished product

Advantage

The vacuum sugar boiling temperature, time, pouring temperature and pouring speed are controlled by computer

The 10.7-inch touch screen displays the process flow chart, the working status of each part, as well as parameters such as temperature and pouring speed

Variable frequency speed regulation controls the accurate flow rate of sugar liquid, ensuring stable quality of sugar paste

Candies of various shapes can be produced according to different molds

By replacing some devices and molds, this production line can produce spherical, flat and three-dimensional lollipops

Easy to operate and maintain

Non-standard machines can be customized according to the site requirements of customers

Fully automatic servo-controlled hard candy casting production line

This casting production line is a hard candy production equipment. It is composed of an automatic weighing system, a pressure dissolution system, a film sugar boiling unit, a pouring unit and a cooling system. It is an improved model of the hard sugar pouring unit, and the pouring unit is driven and controlled by a servo system.

Model ZY1200-S servo casting hard candy production line

Output :1200kg/h

Candy weight: According to the size specified by the customer

Pouring speed :55-65n/min

Steam demand :650kg/h,0.5-0.8MPa

Compressed air demand :0.45m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%

Overall power :48kw/380v

The overall length of the machine is 22 meters

Total weight of the whole machine: 7,500 kg

Model ZY600-S servo casting hard candy production line

Output :600kg/h

Candy weight: According to the size specified by the customer

Pouring speed :55-65n/min

Steam requirement :500kg/h,0.5-0.8MPa

Compressed air demand :0.3m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%

Overall power :38kw/380v

The overall length of the machine is 20m

Total weight of the whole machine :5000kg

Model ZY450-S servo casting hard candy production line

Output :450kg/h

Candy weight: According to the size specified by the customer

Pouring speed :55-65n/min

Steam demand :400kg/h,0.5-0.8MPa

Compressed air demand :0.25m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%

Overall power :34kw/380v

The overall length of the machine is 17 meters

Total weight of the whole machine: 4,500 kg

Model ZY300-S servo casting hard candy production line

Output :300kg/h

Candy weight: According to the size specified by the customer

Pouring speed :55-65n/min

Steam requirement :300kg/h,0.5-0.8MPa

Compressed air demand :0.2m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%

Overall power :27kw/380v

The overall length of the machine is 17 meters

Total weight of the whole machine :4000kg

Model ZY150-S servo casting hard candy production line

Output :150kg/h

Candy weight: According to the size specified by the customer

Pouring speed :55-65n/min

Steam demand :250kg/h,0.5-0.8MPa

Compressed air demand :0.2m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%

Overall power :18kw/380v

The overall length of the machine is 15 meters

Total weight of the whole machine: 3,500 kg

The process flow of the servo hard candy casting production line

Automatic weighing supporting system - Sugar dissolving - storage tank - Vacuum film boiling machine - servo casting machine - cooling tunnel - demolding - conveying - packaging - finished product

Servo-controlled hard sugar pouring machine production line

The sugar pouring machine production line is a fully automatic candy production line that adopts a double film boiling system and double pouring machine heads to achieve high output. Under the premise of highly centralized automatic control, this equipment reduces manual control, thereby lowering labor costs. The casting machine in this production line adopts a new type of long strip mold, which further improves the production efficiency without increasing the cost.

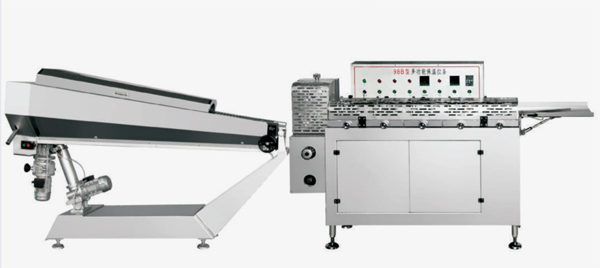

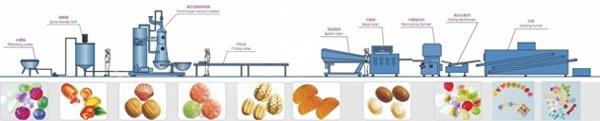

Fully automatic hard candy die stamping production line

Fully automatic hard candy die stamping production line

-This production line can produce various types of die-cut hard candies.

-The fully automatic hard candy die production line can produce various solid hard candies, sandwich hard candies, irregular-shaped hard candies, colored hard candies and other kinds of hard candies

-Vacuum continuous sugar blanking ensures the quality of sugar paste. The unique forming method ensures a good filling effect.

-The production capacity can reach 200 to 1,000 kilograms per hour. Synchronous automatic control, including filling, uniform shaping and forming. Changing the molds can produce candies of different shapes.

-The conveying and cooling system ensures the cooling effect of the candies. When equipped with an automatic lollipop forming machine, spherical lollipops can be produced.

The process flow of the fully automatic hard sugar die stamping production line

Sugar dissolving - storage tank - Vacuum boiling pot - cooling table - Conveyor - Insulated rolling bed - Pulling machine - Candy forming machine - cooling screen - packaging machine

Main equipment

Vacuum continuous boiling pot

It has the functions of automatic sugar boiling and automatic temperature control, with high output, fast sugar boiling speed, and the syrup produced has high transparency

①. Sugar dissolving pot

Capacity :300L

Weight (kg):280

Overall dimensions (mm):1100*1100*1700

②. Sugar storage tank

Capacity (L):300

Weight (kg):220

Overall dimensions (mm):740*740*1250

③. Technical parameters

Production capacity (kg/h):350-400

Heating area (m³):2.45

Steam pressure (MPa):0.7-1.0

Steam consumption (kg/h): approximately 100

Sugar solution entry temperature (°C):110-115

Discharge temperature (°C):135-145

Power - fixed displacement pump (kw):0.75

Matching power - Vacuum pump (kw):5.5

Overall dimensions (mm):1900*1700*2300

Overall weight (kg):800

Insulated roller bed drawing machine

Usage: Suitable for keeping sugar paste warm and pulling it into strips.

Features: Simple operation, labor-saving, and high efficiency.

Technical parameters

The maximum capacity of the roller bed (m³) : 0.20

Extrusion speed (m/min):≤40

Total power (kw):7

Weight (kg):850

Overall dimensions (mm): Four wheels :4270*890*1700

Overall dimensions (mm): Five wheels :4525*890*1700

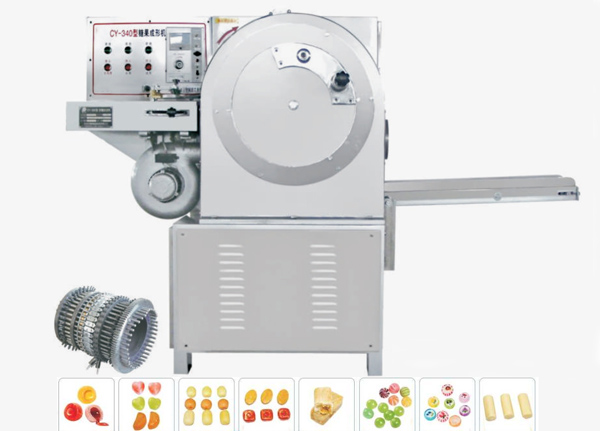

Multi-functional candy forming machine

Usage: It is suitable for the production of hard candies, sandy milk candies, toffee and filled candies, and can also be used in the production of crispy candies (the shape of the candies can be customized according to customer requirements), such as spherical, flat round, oval and various irregular shapes.

Features: Stamping forming, smooth operation, and high output.

Technical parameters

Production capacity: w250kg/h

Total power r: 2.4kw

Weight: 800kg

Overall dimensions: 2000 x 1100 x1300mm

Irregular-shaped candy forming machine

Application: It is suitable for the production of irregular-shaped lollies, such as flat round, oval, large foot board and cartoon irregular-shaped lollies (shapes can be customized according to customer requirements).

Features: It adopts top pressure stamping forming, which is simple to operate, highly efficient and labor-saving.

Technical parameters

Production capacity: 150-250pcs/min

Finished product weight: 10-20g per piece

Total power: 2.5kw

Weight: 1550kg

Overall dimensions: 1950x860x1640mm

Extruder

Technical parameters

Production capacity (kg/h):200-300

Total power (kw):11

The dimensions of the Xibo shape are 1380x500x1480

Machine weight (kg):1100

The extrusion molding machine is suitable for the extrusion of various sugar bars such as hard candies and nougat. The shapes of the sugar strips it extrudes can be divided into colored strip shapes and sandwich shapes. The production of sandwich sugar strips requires a filling machine. This machine is equipped with different types of extrusion heads (double die heads and triple die heads), which can respectively extrude sugar strips of different forms. The products can be classified as sandwich, colored strip, or colored strip sandwich type. This machine can continuously extrude and is used in conjunction with stamping forming equipment. It is a key device for producing colored strip-shaped stamped candies

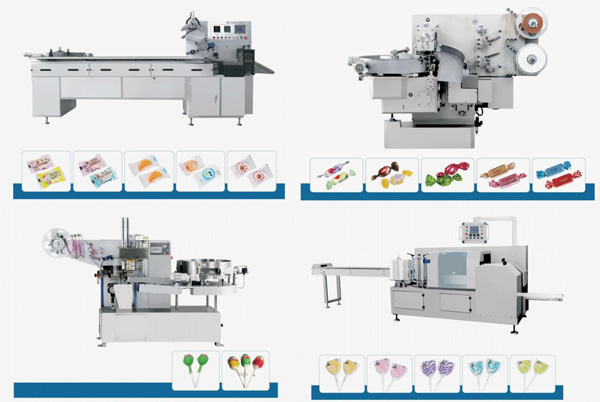

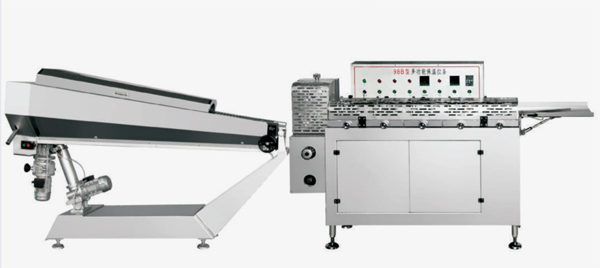

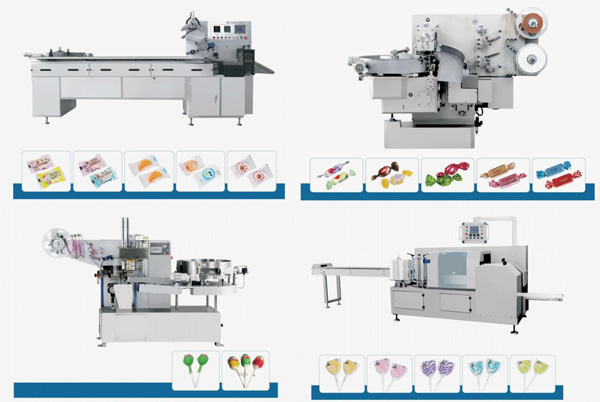

Computerized multi-functional pillow packaging machine

It is suitable for the granular packaging of regular candies and some irregular-shaped candies, such as: rectangular, square, round, spherical, cylindrical, oval, etc.

Characteristics

Variable frequency speed regulation photoelectric tracking, simple operation, smooth running, high speed and high output

Purpose

Suitable for granular packaging of candies and other solid regular items, such as: rectangular,

Technical parameters

High-speed fully automatic double twist packaging machine

Characteristics

It is easy to operate, saves labor, runs smoothly, has low noise and is convenient for maintenance.

The main components adopt imported precision wheels for intermittent segmentation and CAM transmission mechanisms, ensuring that each action is accurate and in place.

The AC motor is equipped with a frequency converter to achieve stepless speed control and can be dynamically adjusted during operation.

- Fully automatic PLC computer controller, photoelectric sensor detection, photoelectric detection, bidirectional tracking.

It has functions such as overload protection, leakage protection and membrane-free alarm.

The food contact parts are made of stainless steel, which has a good smoothness and is easy to clean.

Single-layer or double-layer packaging film can be used, and an automatic hopper can be configured.

Fully automatic spherical candy twisting packaging machine

Purpose

Suitable for twisted packaging of spherical lollipops.

Characteristics

The automatic sugar processing feeding device is aesthetically pleasing, low-noise, stable in operation and easy to maintain.

The AC motor is equipped with a frequency converter to achieve variable speed control

- Fully automatic computer control, photoelectric color mark tracking.

The photoelectric sensor detection, bidirectional tracking, features fast tracking, accurate patterns, and can effectively eliminate packaging errors.

The food contact components are made of stainless steel, which is easy to clean and meets hygiene requirements.

Irregular-shaped candy twisting packaging machine

Uses and Characteristics

It adopts a numerical control display screen, which is convenient and intuitive to operate. The system control is stable and any parameters can be adjusted without stopping the machine. It adopts an electronic film pulling system for smoother speed and an independent temperature control system. Material sorting, tape making, sealing and cutting, knotting and packaging are completed. The machine comes into direct contact with the stick

Sandwich hard candy production line

Sandwich hard candy production line

The process flow of the fully automatic hard candy die filling hard candy production line

Sugar dissolving - storage tank - Vacuum boiling pot - cooling table - Conveyor - Insulated rolling bed - Pulling machine - Candy forming machine - cooling screen - packaging machine

Cylindrical, spherical and fancy hard candy production lines

The process flow of cylindrical, spherical and fancy hard candy production lines

Sugar dissolving - storage tank - Vacuum boiling pot - cooling table - insulated rolling bed - drawing machine - Rotary cutting machine - cooling screen - packaging machine

Spherical lollipop production line

The production process of spherical lollipops

Sugar dissolving - storage tank - Vacuum boiling pot - cooling table - Insulated rolling bed - Pulling machine - Spherical lollipop forming machine - Cooling cabinet - packaging machine

Special-shaped lollipop production line

The process flow of the special-shaped lollipop production line

Sugar dissolving - storage tank - Vacuum boiling pot - cooling table - Insulated rolling bed - Pulling machine - Irregular lollipop forming machine - Conveyor belt - packaging machine

Wavy candy/cane candy production line

The process flow of the special-shaped lollipop production line

Sugar dissolving - storage tank - Vacuum boiling pot - cooling table - Insulated rolling bed - Stretching machine - Creasing machine - New type of special-shaped lollipop forming machine - Cane candy machine - Conveyor belt - packaging machine

Nougat/Block milk candy production line

The production process flow of nougat/block milk candy production line

Sugar dissolving - storage tank - Vacuum gas-filled stirring milk candy boiling machine - cooling table - nougat machine - packaging machine

Milk candy production line

Sandwich milk candy production line

The process flow of the sandwich milk candy production line

Sugar dissolving (electric heating sugar boiling pot) - Storage tank - Vacuum gas-filled stirring milk candy sugar boiling machine (mixer) - cooling table - Slurry conveying machine - insulated rolling bed - drawing machine - conveyor belt - candy forming machine - cooling screen - packaging machine

Cylindrical milk candy production line

The process flow of the cylindrical milk candy production line

Sugar dissolving (electric heating sugar boiling pot) - Storage tank - Vacuum gas-filled stirring milk candy sugar boiling machine (mixer) - cooling table - insulated rolling bed - pulling machine - conveyor belt - rotary cutting and forming machine - cooling screen - packaging machine

Large cylindrical milk candy production line

The process flow of a large cylindrical milk candy production line

Sugar dissolving - storage tank - Vacuum gas-filled stirring milk candy boiling machine - cooling table - Large cylindrical milk candy production line - packaging machine

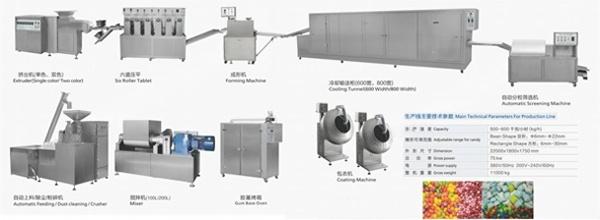

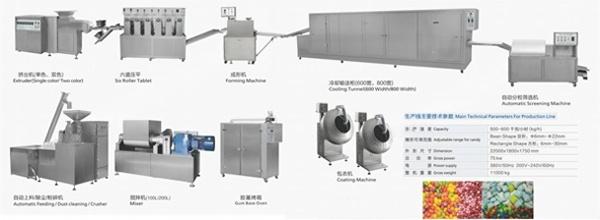

Xylitol chewing gum crispy milk candy production line

This production line is suitable for the production of xylitol chewing gum and milk candy crisps. This equipment is composed of a mixer, an extruder, six flattening machines, a forming machine, a cooling and conveying cabinet, an automatic granulator, a gum base oven and a coating machine, forming a fully automatic production line. It can produce candies of various shapes (such as square, rectangular, sheet, etc.). The whole machine is reliable in production, flexible and easy to operate, and has a high degree of automation. It is a device for producing xylitol chewing gum and crispy milk candies.

The production process flow of xylitol chewing gum and crispy milk candy

Mixer - Extruder - six-pass flattening - Forming machine - Cooling conveying cabinet - Automatic granulator - Adhesive base - Oven - Coating machine - Packaging machine

Main technical parameters of the production line

Production speed :500-600 kilograms per hour (kg/h)

Adjustable range of sugar shape: Bean shape: 6mm-22mm; Square: 6mm-30mm

Overall dimensions: 22000x1800x1750mm

Total power efficiency :75 kw

Power supply :380V/50HZ, 200V-240V/60HZ

The total weight of the machine is 11,000 kg

Main technical parameters of the single machine

Automatic feeding/dust removal crusher: Power :17kw, Dimensions :3500x1300x2200 mm, Weight :400 kg

Rubber-based oven: Power :18kw, Dimensions :1600x600x1700mm, Weight :300kg

Mixer -100L: Power: 20 kw, Dimensions :2300x860x1550 mm, Weight t:1500 kg

Mixer -200L: Power: 24kw, Dimensions: 2650x1000x1650mm, Weight: 2000kg

Extruder - Single color: Power: 15kw, Dimensions: 2500x900x1500mm, Weight: 1000kg

Extruder - Two-color: Power:22 kw, Dimensions :2600x1150x1500 mm, Weight :2200 kg

Six-channel flattening: Power :5 kw, Dimensions :5100x950x1880 mm, Weight :2000 kg

Forming machine: Power: 2.2kw, External dimensions: 1800x780x1650mm, Weight :800 kg

Cooling conveyor cabinet -600 width: Power :20 kw, external dimensions :8850x1900x1850 mm, weight :2500 kg

Cooling conveyor cabinet -800 width: Power :22 kw, external dimensions :8850x2100x1850 mm, Weight :2700 kg

Automatic bud separation and screening machine: Power :3 kw, external dimensions :2200x1000x1400 mm, Weight :350 kg

Sugar coating machine: Power :2 kw, Dimensions :1050x1050x1600 mm, Weight :350 kg

Irregular-shaped milk candy and bubble gum forming production line

This machine is suitable for the formation and production of various shaped milk candies and bubble gum candies. The entire production line consists of a mixer, an extruder, a cooling conveyor cabinet, a three-layer conveyor belt, six forming machines, a sugar coating machine, two square sauce forming machines, and a gummy oven. It can produce hollow candies with powder and paste in shapes such as spherical, strawberry, olive, and cylindrical.

The process flow of the irregular-shaped milk candy and bubble gum forming production line

Mixer - Extruder - Cooling conveyor cabinet - Three-layer conveyor belt - Forming machine - Sugar coating machine - Square sauce filling forming machine - Gum base oven

Main technical parameters of the production line

Production speed :400-650 kilograms per hour (kg/h)

Sugar shape diameter :10-25 mm

Dimensions :15000x4000x1500 mm

Total power :82 kw

Power supply :380V

The total weight of the machine is 8,850 kg

Main technical parameters of the single machine

Automatic feeding/dust removal crusher: Power :17kw, Dimensions :3500x1300x2200 mm, Weight :400 kg

Rubber-based oven: Power :18kw, Dimensions :1600x600x1700mm, Weight :300kg

Mixer -100L: Power :20 kw, Dimensions :2300x860x1550 mm, Weight :1500 kg

Mixer -200L: Power: 24kw, Dimensions: 2650x1000x1650mm, Weight: 2000kg

Extruder - Single color: Power :15 kw, Dimensions :2500x900x1500 mm, Weight :1000 kg

Extruder - Two-color r: Power :22 kw, Dimensions :2600x1150x1500 mm, Weight :2200 kg

Sandwich pump: Power :3 kw, Dimensions :1600x550x1650 mm, Weight :300 kg

Cooling conveyor cabinet l-600 width: Power :20 kw, external dimensions :8850x1900x1850 mm, weight :2500 kg

Cooling conveyor cabinet -800 width: Power :22 kw, external dimensions :8850x2100x1850 mm, Weight :2700 kg

Three-layer conveyor belt: Power: 2.3kw, Dimensions: 10500x900x1450mm, Weight: 300kg

Forming machine: Power: 1.5kw, External dimensions :1320x950x1600 mm, Weight :400 kg

Square sauce filling machine: Power: 2.2kw, external dimensions :1200x1200x1300 mm, Weight :650 kg

Sugar coating machine: Power :2kw, Dimensions :1050x1050x1600 mm, Weight :350 kg

Milk candy bubble gum production line

Main performance

This machine is an automatic production line integrating shaping, cutting and packaging. It is suitable for the shaping, cutting and packaging of milk candies, bubble gum and toffee. It has the advantages of high production efficiency and low sugar content. Products of various shapes and specifications can be produced according to the requirements of customers. Such as chewing gum, sheet shapes of Swiss sugar, rectangular and round fillings, color fillings, fillings, etc.

The process flow of the milk candy and bubble gum production line

Automatic feeding/dust removal/pulverizer - mixer - extruder - cooling conveyor cabinet - block pillow packaging machine - low-temperature double vacuum gas-filled mixing pot - glue-based oven

Main technical parameters of the production line

Production speed :750-850 kilograms per hour

Power supply :380V

Total power efficiency r:143 kw

Overall dimensions :17300X5500X1800 mm

Adjustable range of sugar shape :18-80 mm

The total weight of the machine is 15,000 kg

Main technical parameters of the single machine

Automatic feeding/dust removal/pulverizer: Power :17 kw, External dimensions :3500x1300x2200 mm, Weight :400 kg.

Mixer 100L: Power: 20kw, Dimensions: 2300x860x1550mm, Weight: 1500kg

Mixer -200L: Power: 24kw, Dimensions: 2650x1000x1650mm, Weight: 2000kg

Extruder - Single color: Power :15kw, Dimensions: 2500x900x1500mm, Weight: 1000kg

Extruder - Two-color: Power: 22 kw, Dimensions :2600x1150x1500 mm, Weight: 2200 kg

Sandwich pump: Power :3 kw, Dimensions :1600x550x1650 mm, Weight :300 kg

Cooling conveyor cabinet -600 width: Power :20 kw, external dimensions :8850x1900x1850 mm, weight: 2500 kg

Cooling conveyor cabinet -800 width Power :22 kw, external dimensions :8850x2100x1850 mm, Weight :2700 kg

Block pillow packaging machine (unit): Power :4 kw, External dimensions :2150x900x1500 mm, Weight :980 kg

Low-temperature double vacuum gas-filled stirring pot: Power: 29 kw, Dimensions: 3300x1600x3200 mm, Weight: 2500 kg

Rubber-based oven: Power :18kw, Dimensions :1600x600x1700mm, Weight: 300kg

Tablet sugar production line

This production line, from material crushing, raw material mixing, granulation, dehumidification to tablet forming, can customize square, round, oval and various shaped tablet products for food and medicine according to customer needs.

The process flow of the tablet sugar production line

Crusher - Trough type tilting mixer - Trough type vertical mixer - Swing type granulator - Rotary granulator - Rotary tablet Press - Whistle Candy Bonding machine - Dehumidifier

Technical parameters of rotary tablet press

Model :ZY-17

Die number r:17 pairs

Power supply :380V/50Hz

Power :2.2kw

Production speed: 25,000-110,000 pieces per hour (pc/h)

Maximum tablet pressing pressure (Max.):40kn

Maximum tablet diameter (Max.):25mm

Maximum filling depth (Max.):15mm

Maximum tablet thickness (Max.):6mm

Turntable speed :11-28(r/min)

Dimensions :900*850*1600mm

The total weight of the machine is 850kg

Model :ZY-31

Number of dies :31 pairs

Power supply :380V/50Hz

Power :5.5kw

Production speed: 45,000-130,000 pieces per hour (pc/h)

Maximum tablet pressing pressure (Max.):80kn

Maximum tablet diameter (Max.):21mm

Maximum filling depth (Max.):15mm

Maximum tablet thickness (Max.):6mm

Turntable speed :14-36(r/min)

Overall dimensions :1180*11500*1650mm

The total weight of the machine is 1800kg

Model :ZY-33

Number of dies :33 pairs

Power supply :380V/50Hz

Power :5.5kw

Production speed: 45,000-145,000 pieces per hour (pc/h)

Maximum tablet pressing pressure (Max.):80kn

Maximum tablet diameter (Max.):18mm

Maximum filling depth (Max.):15mm

Maximum tablet thickness (Max.):6mm

Turntable speed :14-36(r/min)

Overall dimensions :1180*11500*1650mm

The total weight of the machine is 1800kg

Main technical parameters of the single machine

Powder crusher: Power :15kw, Dimensions: 980x780x1430mm, Weight: 300kg

Trough type tilting mixer: Power :4 kw, Dimensions :1700x590x1130 mm, Weight :300 kg

Trough type vertical mixer: Power: 2.2kw, external dimensions: 1820x720x1450mm, Weight: 350kg

Swing granulator: Power :3 kw, Dimensions :950x700x1160 mm, Weight :250 kg

Rotary granulator: Power :3kw, Dimensions: 1220x540x1350mm, Weight: 250kg

Whistle candy bonding machine: Power: 0.75kw, Dimensions: 1350x750x1650mm, Weight :350 kg

Dehumidifier: Power: 3.7kw, Dimensions :950x440x1860 mm, Weight :200 kg

Chocolate forming production line

Main performance

This machine is a dedicated equipment for chocolate casting and shaping, integrating mechanical and electrical control. The entire production process includes automatic working procedures such as casting, vibrating the mold, cooling, demolding, conveying, and drying the mold.

This machine can produce pure chocolate, filled chocolate, soft-filled granular cast chocolate, left and right two-color chocolate, four-color chocolate, and chocolate production equipment

Main technical parameters of the production line

Power supply :380V/50HZ

Total power :300-500 kilograms per hour (kg/h)

Overall dimensions :18000x1200x2200 mm

Template specification :470 x 200 x 30 mm

Template quantity :280 pieces (PCS)

Weight: 6,200 kg

Chocolate bean production line

Main performance

There are two different processing methods for chocolate beans. One is formed from chocolate powder, and the other is formed from chocolate liquid. The complete chocolate production line, composed of fine grinding cylinders, insulated buckets, crushers, vibrating screens, forming machines, chillers and pelletizers, etc., is suitable for the production of high-quality chocolates of various shapes (such as round chips, bean-shaped, olive-shaped, etc.).

Main technical parameters of the production line

Power supply :380V/50HZ

Total power :35kw

Production speed :350-500 dry grams per hour

Overall dimensions :6200x1350x1900 mm

Hard candy types (candy shapes) and applications

It is suitable for casting and punching out hard candies, sandy milk candies, toffee, filled candies, irregularly shaped lollipops, flat lollipops and threaded flower candies of different shapes. Cylindrical and spherical candies, milk candies, cane candies, nougat candies, etc

The working principle of the hard candy machine

1. Components of the hard sugar casting forming machine: conveyor belt, mold tray, sugar injection nozzle, sugar pouring pump, storage tank, cooling device. Casting mold forming can produce hard candies, soft candies and soft candies. It has a wide range of applications and the equipment required is roughly the same. During the mold casting process, when the boiled sugar paste is still in an active state, the liquid sugar paste is quantitatively injected into the continuously running model tray, then rapidly cooled and shaped. After that, it is separated from the model tray and sent to the packaging machine along the conveyor belt for packaging.

2. Continuous stamping forming: When the sugar dough cools to an appropriate temperature, stamping forming can be carried out. If the temperature is too high, the sugar body will be too soft and difficult to shape. Even if sugar blocks are formed, they are prone to sticking together or deforming. If the temperature is too low, the sugar dough will be too hard, and the formed sugar grains are prone to fuzz, darkening, and missing edges and corners. The suitable temperature for stamping forming is 80-70℃. At this temperature, the sugar dough is malleable. Stamping forming takes advantage of the characteristics of the sugar dough at this temperature range. The sugar dough is stretched into strips by a drawing machine or manually and then sent into the forming machine for stamping forming.

When performing stamping forming, it is necessary to pay attention to the temperature and relative humidity in the forming workshop as well as the temperature of the die surface of the forming machine; otherwise, it is easy to cause broken bars or adhesion of the machine tools. The temperature in the molding chamber should not be lower than 25℃ and the relative humidity should not exceed 70%.

3. Extruded hard candies: This production line is composed of a mixer, an extruder, a forming machine, a cooling and conveying cabinet, an automatic granulator, a gum base oven and a coating machine, forming a fully automatic production line. It can produce candies of various shapes (such as square, rectangular, sheet, etc.). The whole machine is productive and reliable, easy and flexible to operate, and has a high degree of automation.

Installation of the hard candy production line

We will send engineers to help you install the machine

Some main equipment

Some main equipment