Hollow board production machinery

This production line has high output and excellent automatic control.The hollow board production line manufactured by our company is currently the world's leading model. This production line has high output and excellent automatic control. It can produce various ordinary hollow boards, conductive hollow boards, as well as various packaging boxes, turnover boxes, partition plates, box lining plates, luggage lining plates, sunshades, etc. of hollow boards. The materials used are PE and PP. It can produce various ordinary hollow boards, conductive hollow boards, as well as various packaging boxes, turnover boxes, partition plates, box lining plates, luggage lining plates, sunshades, etc. of hollow boards. The materials used are PE and PP. The width ranges from 1200mm to 2700mm, and the thickness is from 2mm to 8mm. The width ranges from 1200mm to 2700mm, and the thickness is from 2mm to 8mm. The products are widely applied in electronic light industry, food machinery, post and telecommunications, aquatic appliances, advertising decoration, building materials, etc. The products are widely applied in electronic and light industry, food machinery, post and telecommunications, aquatic appliances, advertising decoration, building materials, etc.

The configuration list of the plastic sheet extrusion production line includes:

- Single screw extruder

- Non-stop hydraulic screen changer

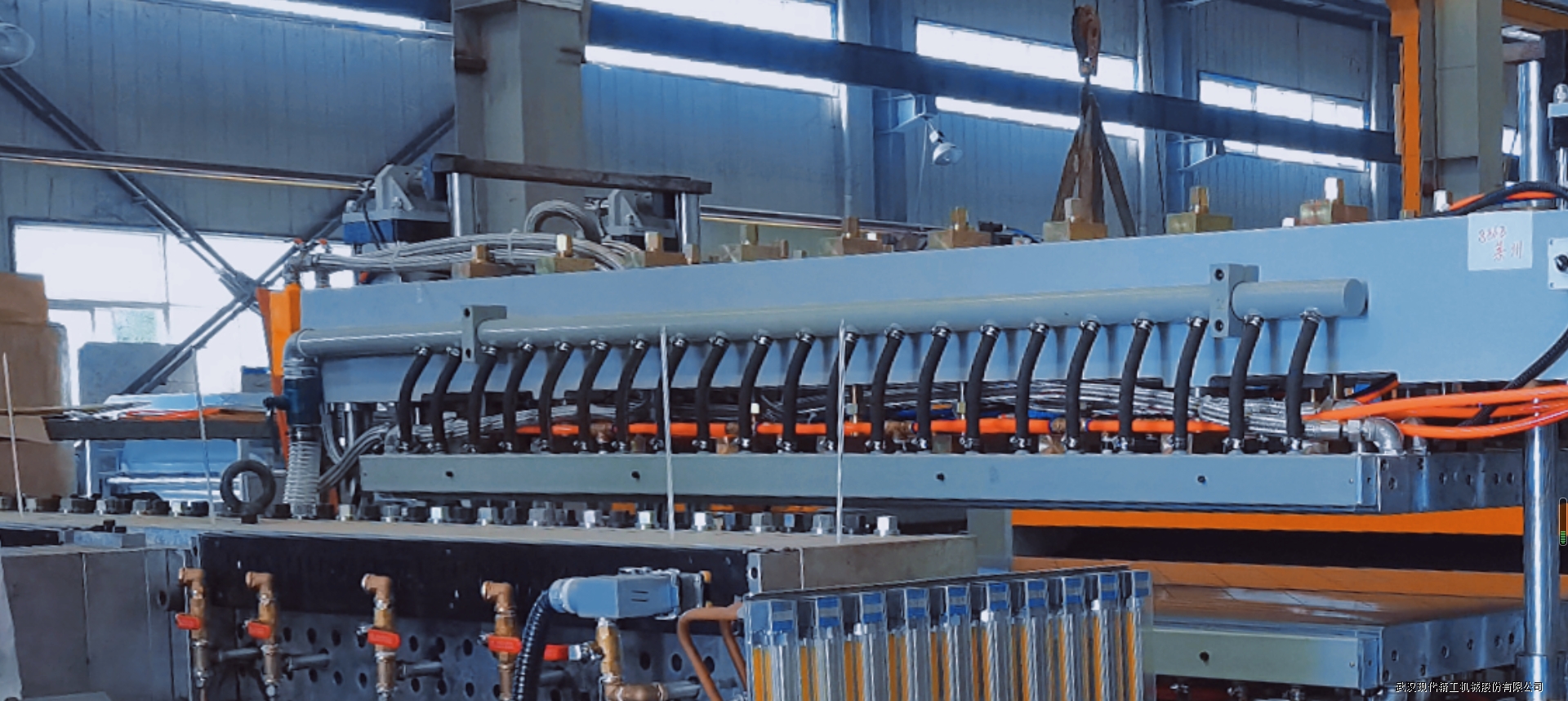

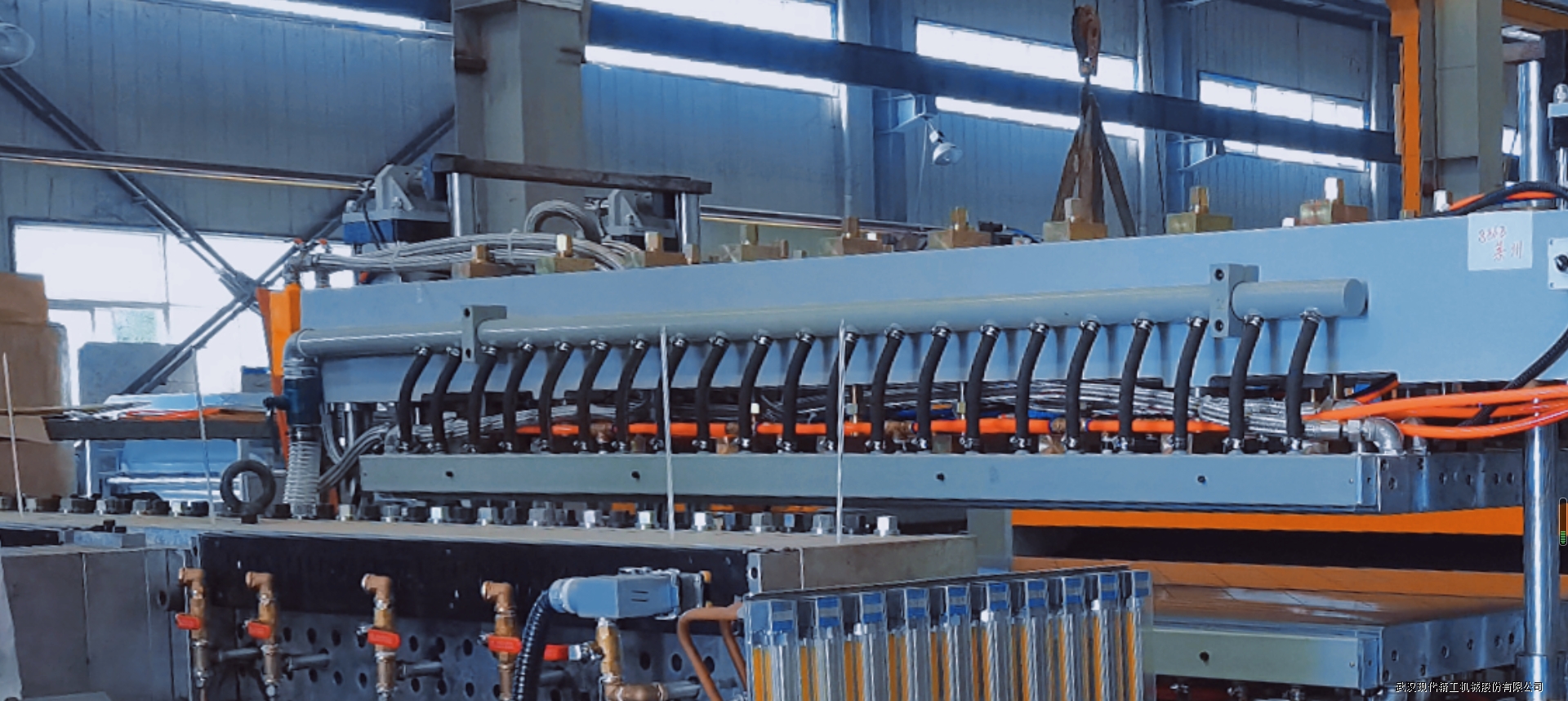

- Mold

- Stabilization table

- First traction

- Oven

- Cooling section

- Second traction

- Shearing section

- Electrical control cabinet

- Storage table

- Spiral feeder

The entire set of hollow board production line manufactured by our company features all key components such as feeding system, extruder, molds, shaping machine, tensioning and cutting equipment, which are all designed and manufactured by our company. This ensures the stability of the mechanical product quality.

Extruder: Unique design of the screw, outstanding temperature control system, ensuring stable plasticizing performance and extrusion efficiency. The outstanding feature of our company is high energy efficiency. For the same output, the motor power is saved by 20%.

Mold: Superior alloy mold lip and adjustable flow-blocking block, providing uniform pressure

Vacuum calibrator: The array interlacing of the thermal convection system ensures calibration. The calibration of the vacuum system. The vacuum system consists of two separate subsystems, equipped with a large number of closed-loop vacuum lines.

Electrical control system: Utilizes the microprocessor unit PLC to control parameters and has optimized the operation characteristics.

Our company's solution for producing hollow boards includes the following main advantages:

The PP hollow plastic building formwork has high strength, good impact resistance, wear resistance, and a long service life. It can be reused up to 30 times.

2. The PP hollow plastic building formwork has excellent processing properties. It can be sawed, planed, and nailed, and can be used concurrently with wooden formwork.

3. The two surfaces (smooth surface or patterned surface) of the PP hollow plastic building formwork have different functions. For example, when using the smooth surface, after the concrete pouring is completed and the formwork is removed, the surface of the compacted concrete will be flat and smooth, meeting the requirements for decoration and clean appearance. No additional plastering is needed, which saves materials and time, reduces cleaning and maintenance costs, and ensures stable concrete quality and shortens the construction period. It is suitable for use in damp environments such as basement projects, roads, railways, and bridge piers; if using the patterned surface, it will be combined with the plastering layer. When used on bridge piers, the patterned surface can meet the requirements for decoration and clean appearance, and due to the light diffusion reflection effect of the patterned surface, it does not have strong light reflection that affects the driver's vision, thus providing protection.

4. This new type of hollow plastic building formwork is lightweight, easy to assemble and dismantle, has low labor intensity during transportation and operation, high construction efficiency, does not absorb moisture, is corrosion-resistant, resistant to acids and alkalis, and has a smooth and glossy surface. It does not require the application of release agents.

5. The waste boards and leftover materials from this new type of hollow plastic building formwork can be recycled in an environmentally friendly manner, which not only saves costs but also reduces pollution.

6. The overall cost of using this new type of hollow plastic building formwork is more than 30% lower than that of traditional wooden formwork.

7. High efficiency (Production efficiency can be negotiated in a contract. The full payment will be made upon achieving the desired results.)

8. Production (The controllability of product thickness and quality. The same equipment and the same mold can produce products ranging from 2 to 6 millimeters in thickness.)

9. Reliability and stability (There are over 300 Wuhan Modern Precision Engineering's hollow board production lines in operation)

10. Strong adaptability (Our equipment can directly produce products using recycled materials, scraps, and crushed materials, saving production costs by 30%)