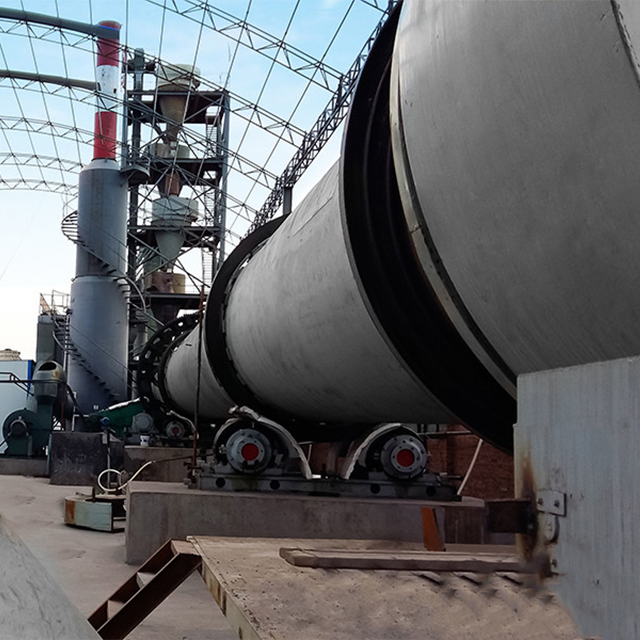

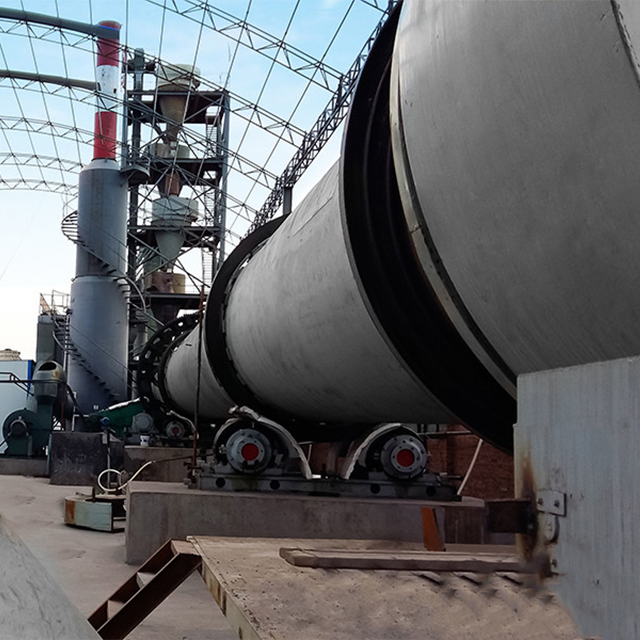

Kaolin rotary kiln

Kaolin has the characteristics of high whiteness, soft quality, easily dispersed suspended in water, and has good plasticity, high cohesiveness, excellent electrical insulation properties, good acid solubility, low cation exchange capacity, good fire resistance and other physical and chemical properties. Therefore, the development of kaolin has increased, and kaolin rotary kiln is the main equipment for the production of kaolin.

Raw materials: coal gangue, etc.

Capacity: 1~ 200,000 tons/year (depending on raw material composition)

Model: Ø1.6×32m-Ø4×80m

Fuel: natural gas, blast furnace gas, coal, etc

Application: Suitable for paint, paper, rubber and plastic products, cable, ceramics and other industries.

Kaolin rotary kiln product introduction

Kaolin rotary kiln is an important equipment in kaolin production and sintering, and the temperature of the rotary kiln is generally required to reach 950℃ or more. Kaolin rotary kiln is also called kaolin calcining kiln, and can also be used for bauxite calcining, magnesium oxide calcining, zinc oxide calcining and so on.

Outstanding advantage

1, kaolin rotary kiln external structure is simple, internal structure is reasonable, easy to install, operation and maintenance;

2, the kiln cylinder operation is very uniform, low heat loss, low power consumption, low failure rate, not only effectively realize the recycling of heat energy, but also reduce the production cost;

3, the sealing in the kiln is more reasonable, effectively prevent the entry of foreign bodies and cold air, but also reduce the spillover of dust, reduce dust pollution, improve the production environment;

4. The equipment is equipped with an automatic cooling device, and the calcined kaolin will automatically enter the cooling device to achieve automatic cooling, which can effectively improve the recovery rate of kaolin materials and increase product output.

Working principle

When the kaolin rotary kiln starts to work, the kaolin raw material enters the cylinder from the kiln tail through the preheater. Due to the inclined installation and slow rotation of the cylinder, the raw material produces a compound movement that rolls along the circumference and moves from the higher end to the lower end along the axis. After the raw materials are decomposed and fired in the kiln, the finished clinker is discharged from the kiln head (low end) and enters the cooling machine.

Technical parameter

| Specifications (m) | Basic parameters (t/h) | Reduction gear | motor | Number of supports (PCS) | Machine weight (t) |

| Rotational speed(r/min) | slope(%) | yield(t/h) | Model number | Model number | Power (kW) |

| φ1.6×32m | 0.58-2.85 | 4 | 2 | ZQ75-50 | YCT250-4A | 18.5 | 3 | 46.8 |

| φ1.6/1.9×36m | 0.53-1.59 | 4 | 2.5-3 | ZQ110-7 | YCTZ50-4B | 22 | 3 | 57 |

| φ1.9×39m | 0.53-1.59 | 4 | 3-3.4 | ZQ125-7 | YCT315-4A | 37 | 3 | 71.79 |

| φ2.2×45m | 0.214-1.64 | 3.5 | 4-5 | The mainZS125-5 | YCT315-4B | 45 | 3 | 142.6 |

| Auxiliary:ZQ40-40 | Y112M-4 | 4 |

| φ2.5×50m | 0.62-1.5 | 3.5 | 5-6 | The main:ZS165-5 | YCT355-4A | 55 | 3 | 180 |

| Auxiliary:ZS50-1 | Y160M-6 | 7.5 |

| φ2.5×55m | 0.62-1.5 | 3.5 | 5-6 | The mainZS165-5 | YCT355-4A | 55 | 3 | 185 |

| Auxiliary:ZS50-1 | Y160M-6 | 7.5 |

| φ2.8×55m | 0.62-1.5 | 3.5 | 6-7 | The mainZS165-5 | YCT355-4B | 75 | 3 | 215.6 |

| Auxiliary:ZS50-1 | Y160L-6 | 11 |

| φ3.0×60m | 0.5-1.5 | 3.5 | 7-9 | The main:ZS165-3 | ZSN-280-11B | 125 | 4 | 310.9 |

| Auxiliary:ZS50-1 | Y160L-6 | 11 |

| φ3.2×64m | 0.4-1.5 | 3.5 | 8-10 | The main:ZS130-16 | ZSN-280-11B | 190 | 4 | 337.8 |

| Auxiliary:ZI50-1 | Y180L-4 | 22 |

| φ3.5×70m | 0.4-1.5 | 3.5 | 12-14 | The main:ZSY500-40 | ZSN-315-082 | 280 | 4 | 394.6 |

| Auxiliary:ZI50-14 | Y180L-4 | 22 |

| φ4.0×80m | 0.4-1.5 | 3.5 | 16-20 | The main:ZLY630-35.5 | ZSN-315-12 | 355 | 4 | 564.8 |

| Auxiliary:ZSY280-35.5 | Y200L-4 | 30 |