Lime production Line _ Complete equipment for lime production

Active lime is mainly made of limestone, dolomite, chalk and other minerals with high calcium carbonate content, calcined at 1100±50℃. There are many kinds of process methods for lime production, mainly: "preheater - rotary kiln - vertical cooling" energy-saving lime production process; Traditional "long rotary kiln" lime production technology; Mixed firing shaft kiln lime production technology; Gas fired or oil fired shaft kiln lime production technology.

The choice of active lime production process is determined by a variety of factors: investment cost, lime activity requirements, fuel selection, raw material granularity, system capacity requirements, environmental requirements. We will determine the production process according to the specific situation and requirements of customers.

Capacity: 100-1200 tons/day

Calcination temperature: 1100±50℃

Fuel: natural gas, gas, coal, oil, etc

Outstanding advantage

Lime can be divided into ordinary lime and active lime two kinds, ordinary lime is mostly fired by earth kiln and ordinary shaft kiln, its activity is generally less than 200ml, mainly for construction and road repair use; Active lime is mainly fired by mechanical shaft kiln and rotary kiln, and its activity can reach 300~420ml. The quality of lime fired by rotary kilns is better, and they are mainly used in iron and steel smelting, chemical industry and power plant desulfurization.

In all the active lime production process, the current use of more or rotary kiln production process, the main feature of the process is the accumulation of shaft kiln preheating effect is good, low heat consumption, rotary kiln temperature field uniform activity of the advantages of high, the use of rotary kiln with vertical preheater and vertical cooler calcined limestone, to achieve energy saving, environmental protection, good activity of the production requirements.

1. Environmental protection: The flue gas discharged by the vertical preheater at the end of the kiln has low temperature and low dust content, which makes the configuration of subsequent flue gas treatment simple and efficient, and meets the requirements of environmental protection.

2, lime activity: the rotary kiln is open calcination, the kiln body structure is simple, the air flow is smooth, the sulfur-containing gas can be discharged in time, the sulfur in the fuel is not easy to adhere, so the product sulfur content is low, meet the requirements of steelmaking. At the same time, the material rolls forward evenly in the kiln, is heated evenly, the product quality is stable, the production and burning rate is very low, and the steel lime with high activity can be calcined.

3. Energy saving and high efficiency: the vertical preheater at the end of the kiln can make full use of the high temperature flue gas produced by calcination in the rotary kiln to preheat the limestone from normal temperature to the initial decomposition state. This can not only greatly improve the output of rotary kiln, but also fully reduce the heat consumption per unit product.

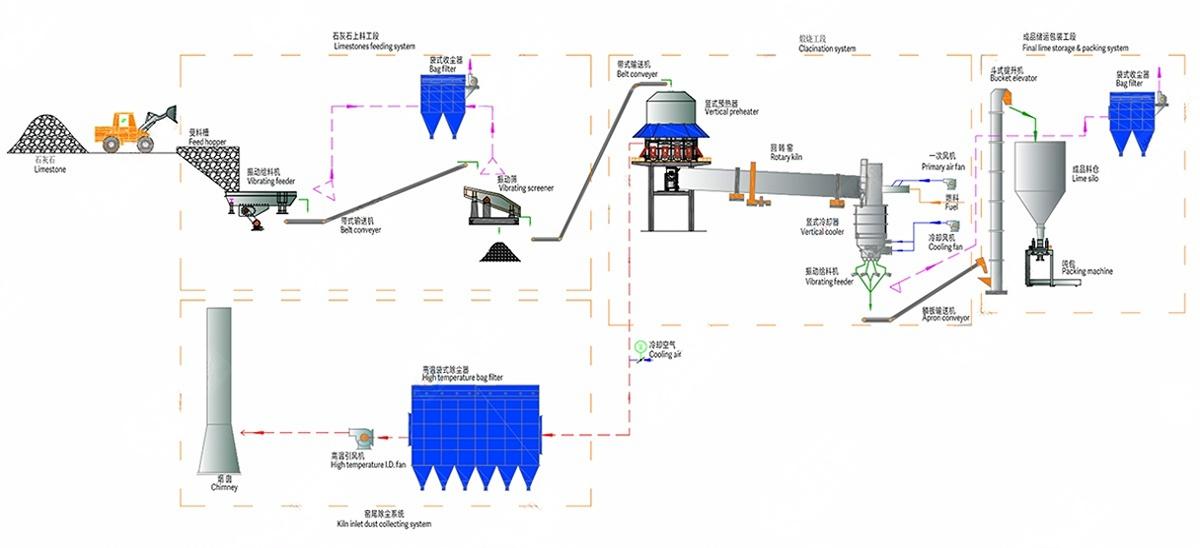

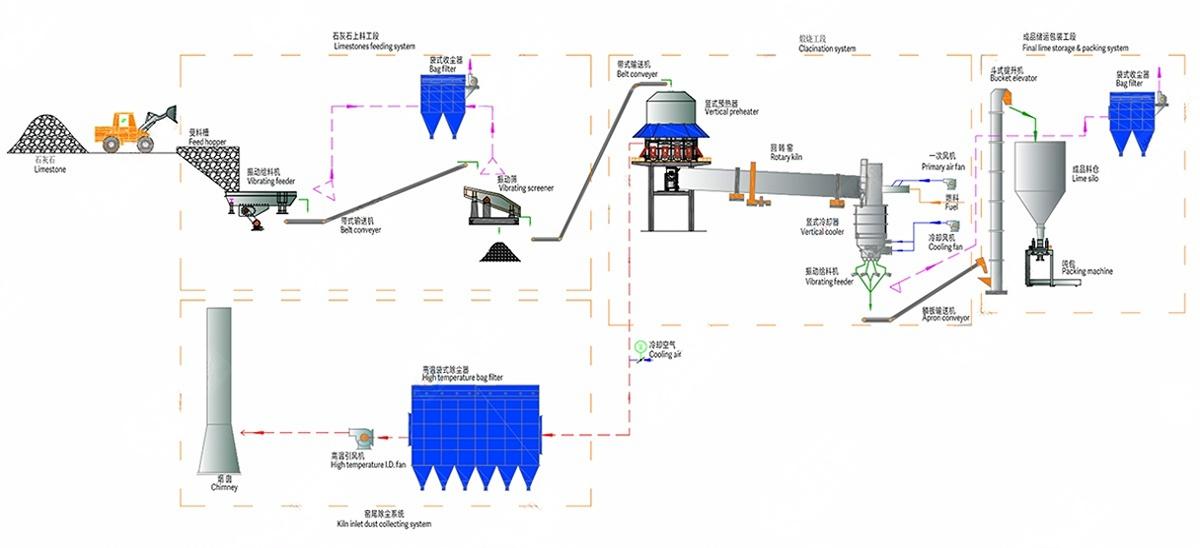

Process flow

(1) Raw material storage and transportation

The limestone with particle size of 10 ~ 50mm is transported to the factory and stacked in the material yard, and the material yard is operated by loaders. The material with qualified particle size is loaded into the receiving trough set up in the material yard by the loader, the receiving trough is fed quantitatively by the feeder, the stone is fed to the high Angle conveyor, and then sent to the screening building. After the qualified particle size of the limestone is screened, it is weighed by the high Angle conveyor and sent to the top silo of the preheater. The powder under the screen is sent to the storage yard by the 3# conveyor and is regularly transported by the forklift truck.

(2) Calcination of limestone

Limestone calcining is composed of vertical preheater + rotary kiln + vertical cooler, the output is 150~1200t/d, the material from the top of the preheater bin through the feed chute into the preheater body, at the same time, the high temperature flue gas from the rotary kiln will preheat the material to more than 1000℃, so that the limestone partial decomposition, and then pushed into the tail of the rotary kiln by the hydraulic push rod. After high temperature calcination in rotary kiln, it is discharged into the cooler, cooled by the cold air blown into the fan, and cooled to the ambient temperature of +60℃ below the cooler. The air blown in by the cooler enters the rotary kiln as secondary air to participate in combustion.

(3) Finished product transportation

After the finished lime is discharged from the cooler, it is transported to each finished lime warehouse by chain conveyor, bucket elevator and belt conveyor. The discharge valve under the lime storage bin is used to load the lime in the bin into the car and the tank car before being transported out. Set up different size silos according to customer reserve requirements.

The finished product silo adopts circular silo, with 2 finished products silos of 5~50mm and 1 finished product silo of <5mm. The quantity of each silo is about 800t.

(4) Flue gas treatment

After heat exchange with limestone in the preheater, the temperature of the high temperature flue gas produced by the combustion of rotary kiln is reduced to below 250℃, and then the cyclone dust collector is carried out for the first stage of dust collection, the large particles of dust are captured, and then into the bag dust collector. After dust removal, the high temperature fan is discharged into the atmosphere, and the dust concentration of the discharged gas is less than 30mg/m3. A cold risk control system is installed at the inlet of the dust collector to protect the dust collector.

Technical parameter

| Capacity (t/d) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 800 | 1000 | 1200 |

| Main equipment | Main supporting equipment models and technical and economic indicators |

| Vertical preheater | YRQ04 | YRQ06 | YRQ06 | YRQ08 | YRQ08 | YRQ10 | YRQ12 | YRQ12 | YRQ14 | YRQ18 | YRQ20 |

| Rotary kiln | φ2.5×40m | φ2.8×43m | φ3.0×48m | φ3.2×50m | φ3.3×52m | φ3.6×55m | φ3.8×58m | φ4.0×60m | φ4.3×65m | φ4.9×70m | φ5.1×72m |

| Vertical cooler | LSF36 | LSF44 | LSF56 | LSF80 | LSF112 |

| Calcination temperature /℃ | 1100±50 |

| Energy Consumption index /(kCal/kg) | 1200±100 | ≤1150 | ≤1100 |

| Power Consumption index /(kW ·h/t) | 40±5 |

| Limestone: lime | 1.7~1.78:1 |

| Lime burning rate /% | ≤5 |

| Lime activity /ml | ≥340(depending on the composition of the limestone) |

| Ash discharge temperature /℃ | Ambient temperature +60 |

| Limestone into kiln particle size /mm | 10~20/20~40 |

| Emission concentration /(mg/Nm3) | ≤10 |

| Number of working days per year/day | ≥340 |

| Overhaul cycle/year | 1~3 |

| Number of operators /(person/shift) | 2~3 |

| Suitable fuel | Pulverized coal, coke oven gas, charcoal furnace gas, converter gas, blast furnace gas, calcium carbide furnace gas, natural gas, diesel oil, heavy oil, liquefied petroleum gas, biomass fuel |