Lithium carbonate production line

Our company is equipped with lemica, spodumene and other raw materials for roasting, acidizing production line products have superior performance, stable working conditions and easy to operate, and are actively recognized by users. The kiln body adopts wireless temperature monitoring system and remote intelligent variable kiln condition control system, which is convenient for the production personnel to adjust the kiln condition remotely in real time. The raw material crystal conversion rate is high, and the waste heat recovery from the kiln tail is used to acidize and replenish heat, and the energy consumption of the production line can be reduced a lot. The cooling equipment adopts closed low-temperature circulation technology, and the dust inlet is equipped with a ring air seal device. The production workshop has a certain position in the field of dust reduction and environmental protection, and effectively improves the operating environment.

Main equipment configuration: Acidizing mixer, roasting kiln, single barrel cooling machine, acidizing kiln, cooling kiln for acidizing kiln, raw material mill, bag dust collector, fan, etc

Capacity: 1000-30000 tons/year

Rotary kiln diameter: 1.5-5.5m

Roasting temperature: ~1250℃

Acidizing temperature: ~350℃

Heat source: natural gas, blast furnace gas, coal

Outstanding advantage

The kiln body adopts wireless temperature monitoring system and remote intelligent variable speed kiln condition control system, which is convenient for the production personnel to adjust the kiln condition remotely in real time.

Conversion rate: spodumene calcination transformation of more than 98%, leaching rate of 95%, leucite leaching rate of more than 90%.

The energy consumption of production line can be reduced by about 20% by acidizing heat recovery from kiln tail.

The cooling equipment adopts water-cooled jacket, and the dust inlet is equipped with a ring air seal device. The production workshop has a certain position in the field of dust reduction and environmental protection, and effectively improves the operating environment.

Process flow

Lithium carbonate production technology

I, baking and dipping section

Conversion roasting: Spodumene concentrate is manually sent from the concentrate warehouse to the bucket elevator to the concentrate warehouse, and then the lithium carbonate kiln tail is added to the disk feeder and the spiral feeder. The concentrate is dried by high temperature gas in the preheating section of the kiln tail. The concentrate is then transformed into a crystalline calcination at a temperature of about 1200℃. Density 3150kg/m3) is converted into β-type spodumene (tetragonal system, density 2400kg/m3, that is, baking material), the conversion rate is about 98%.

Acid roasting: After cooling down in the cooling section, the baking material is discharged from the kiln head, then it is naturally cooled and ground by the ball mill to 0.074mm particle size of more than 90%, then transported to the acidizing and roasting kiln tailings warehouse, and then added to the acid mixing machine by the feeder and screw conveyor with concentrated sulfuric acid (more than 98%) in a certain proportion (concentrated sulfuric acid is calculated as 35% of the equivalent lithium in the baking material. After being evenly mixed with concentrated sulfuric acid (0.21t) per ton of baking material, it is added into the acidizing roasting chamber, and the closed acidizing roasting is carried out at a temperature of about 250 ~ 300℃ for 30 ~ 60min. The β-type spodumene in the baking material reacts with sulfuric acid, and the hydrogen ions in the acid replace the lithium ions in the β-type spodumene. The acidified clinker is obtained by combining Li2O with SO42- into Li2SO4 which is soluble in water.

Slurry leaching and washing: the clinker is cooled and slurry, so that the soluble lithium sulfate in the clinker is dissolved into the liquid phase. In order to reduce the corrosion of the solution to the leaching equipment, the residual acid in the clinker is neutralized with limestone slurry, the pH value is adjusted to 6.5 ~ 7.0, and most of the impurities such as iron and aluminum are removed at the same time. The leaching liquid-solid ratio is about 2.5, and the leaching time is about 0.5h. The leached slurry was filtered and separated to obtain the leached liquid, which contained about 100g/L Li2SO4 (Li2O 27g/L), and the filter cake was the leached residue, with a moisture content of about 35%. In order to reduce the loss of lithium, the leaching residue is washed by reverse agitation, and the lotion is returned to the slurry for leaching.

Leaching solution purification: In the process of acidizing roasting, in addition to alkali metal and sulfuric acid can react to produce soluble corresponding sulfate, other iron, aluminum, calcium, magnesium, etc., also react with sulfuric acid to produce corresponding sulfate. In the leaching process, although some impurities in the clinker can be removed, the remaining impurities remain in the leaching solution, and need to continue to purify and remove to ensure the quality of the product. The leaching solution was purified by alkaline calcium removal method, and the pH value was increased to 11 ~ 12 by alkalizing lime milk (containing CaO100 ~ 150g/L), so that magnesium and iron were hydrolyzed into hydroxide precipitation. Then sodium carbonate solution (containing Na2CO3 300g/L) is reacted with calcium sulfate to produce calcium carbonate precipitation, thereby removing calcium in the leaching solution and calcium brought in by the alkalizing agent lime milk. The alkaline calcium removal slurry is separated by liquid-solid, and the obtained solution is the purification liquid, the calcium-lithium ratio is less than 9.6×10-4, and the filter cake is the calcium slag, which is returned to the slurry for leaching.

Purification liquid evaporation and concentration: purification liquid due to the low concentration of lithium sulfate, lithium precipitation rate is low, can not be directly used for lithium precipitation or lithium chloride, need to first use sulfuric acid to adjust the purification liquid to pH6 ~ 6.5, through the three-effect evaporator evaporation concentration, so that the concentration of lithium sulfate in the concentrated liquid up to 200g/L(including Li2O 60g/L). The concentrated liquid is separated by press filtration, the filtrate is used as the finished liquid for the next process, and the filter cake is returned to the pulp after the slag is finished.

II. Lithium carbonate production section

The finished solution and pure lye (containing Na2CO3 300g/L) were added to the evaporation settling lithium tank, and the evaporation settling lithium (2h after boiling) was carried out. Due to the small solubility of lithium carbonate, the precipitation rate of lithium was about 85%. After lithium precipitation, the primary crude lithium carbonate (containing less than 10% filtrate) and the primary submerged lithium mother liquor were separated by centrifuge while hot.

The mother liquor of primary lithium sedimentation contains a large amount of sodium sulfate and high lithium sulfate (about 15% of the total), adding pure lye (containing Na2CO3 300g/L) for secondary lithium sedimentation, to obtain secondary crude product and secondary mother liquor. After the mother liquor is neutralized by acid, and the pH is adjusted by sodium hydroxide, the by-product anhydrous sodium sulfate and mother liquor are separated by evaporation, crystallization and centrifugation. Anhydrous sodium sulfate was dried by air flow and packaged to obtain by-product sodium powder. The mother liquor is returned to the primary mother liquor.

The primary crude lithium carbonate and the secondary crude adhesive liquid contain impurities such as Na2SO4, and then stir with clean water at about 90℃, the lotion is sent to the alkali, and after washing, the wet fine lithium carbonate is separated by centrifuge while it is hot, and then dried by far infrared dryer, magnetic separation removes the debris such as wire chips dropped by the dryer, and then crushed by air flow and packed into the storage.

This project mainly adds battery grade lithium carbonate production capacity. From the perspective of the overall production process, battery grade lithium carbonate and industrial grade lithium carbonate are basically the same, the difference is that the process control conditions of the two sections of evaporation and sedimentation of lithium are different, that is, the specific gravity of the finished liquid is determined by the hydrometer when the purification liquid is evaporated and concentrated, and the concentration of Li2O in the finished liquid is determined by the flame photometer to ensure that the end concentration of the finished liquid is within the process requirements. When settling lithium, the different opening of the adjusting valve is displayed by the electromagnetic flowmeter to control the feeding speed, and the stirring speed of the agitator is controlled by the frequency converter to adjust the motor speed. The above process control conditions are key technologies of the company.

III. Anhydrous lithium chloride section

The finished solution obtained in the baking and leaching section is double-decomposed with calcium chloride solution, and after the reaction is completed, CaSO4·2H2O is separated and sent for processing to produce CaSO4 products. After separation, LiCl dilute solution was obtained, and β-type -active Al2O3, Na2CO3 and NaOH solutions were added successively to remove SO42-, Ca2+, Mg2+ and other impurities in LiCl dilute solution. After evaporation and concentration, LiCl concentration was increased to 400 ~ 500g/L, and solid NaCl was separated by cooling and filtration. LiCl concentrated solution is obtained. The concentrated LiCl solution is transported to the refining tank, and the company's self-produced refined preparation (the company's patented technology, inorganic components, does not contain toxic and harmful heavy metals) is added to Na+ for replacement reaction, and the ratio of Na+/LiCl in the reaction endpoint solution is controlled to be less than 30ppm. After separation, LiCl finishing solution is obtained. The finished liquid is spray-dried to obtain an anhydrous lithium chloride product with uniform particles.

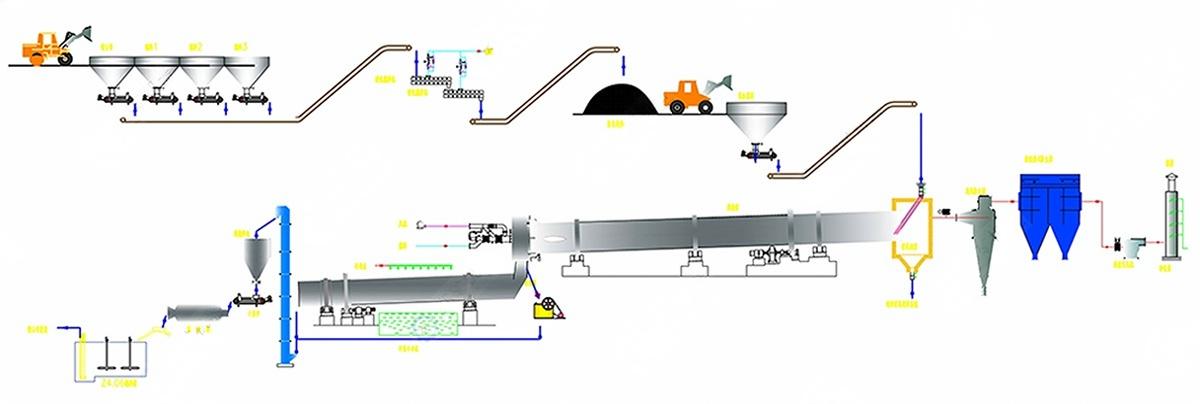

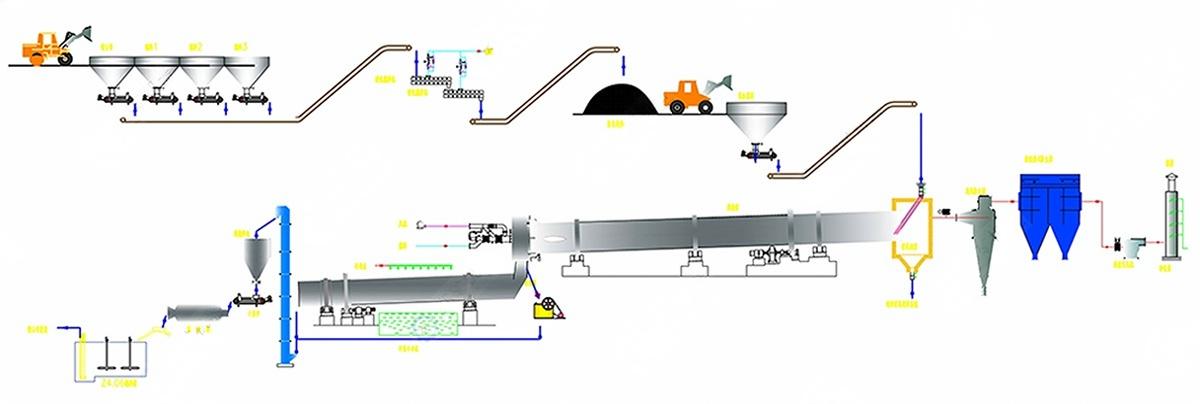

Process flow chart of lithiumite to lithium carbonate

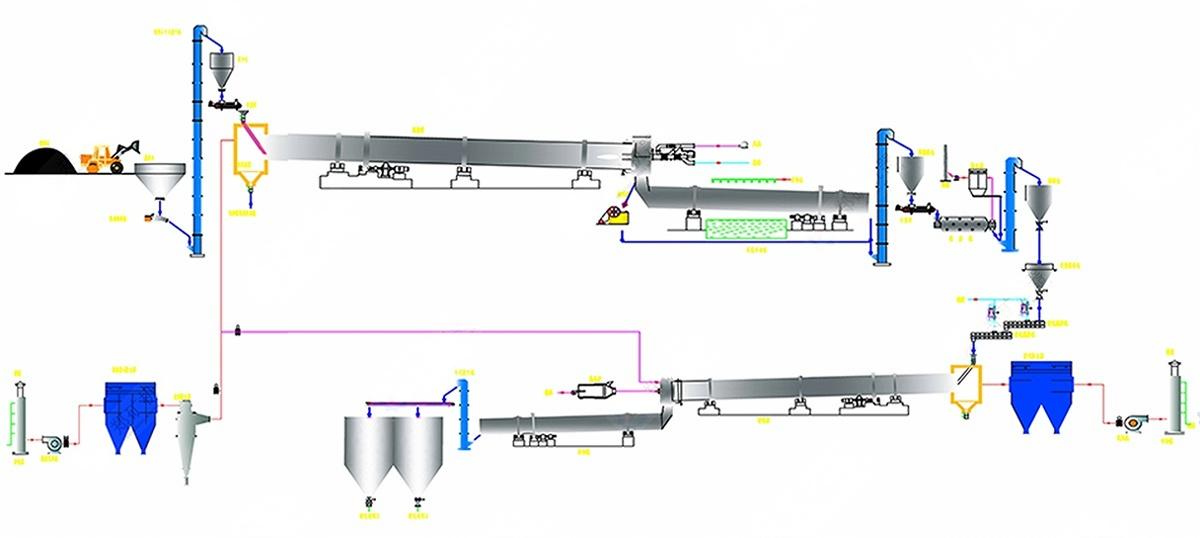

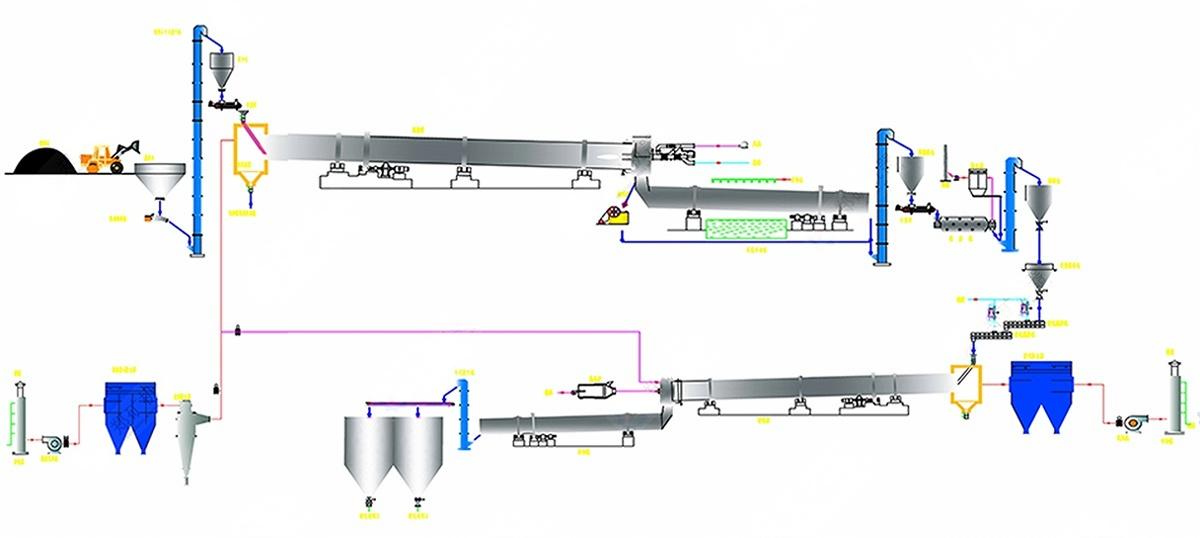

Process flow chart of lithium carbonate from spodumene

Technical parameter

| Spodumene as raw material (no other) |

| Product | Annual production (t/a) | Spodumene content (t/h) | Host equipment type |

| Conversion process | Acidizing process | Ball mill |

| Lithium carbonate | 5000 | 5-6 | Roasting kiln:

Phi 2.8 x 50 m; Cooling machine:

Phi 2.6 x 40 m | Acidizing kiln:

Phi 2.8 x 50 m; Cooling machine:

Phi 2.4 x 35 m | φ1.83×6.4m |

| Lithium carbonate | 10000 | 10-12 | Roasting kiln:

Phi 3.5 x 60 m; Cooling machine:

Phi 2.4 x 40 m | Acidizing kiln:

Phi 3.5 x 50 m; Cooling machine:

Phi 2.4 x 40 m | φ2.4×8m |

| Domestic standard 20,000 tons of lithium carbonate production line (associated with other products) configuration list |

| Product name | Annual production (t/a) | Spodumene content (t/h) | Host equipment type |

| Conversion rotary kiln | Acidizing rotary kiln | Ball mill |

| Battery grade lithium carbonate | 10000 | 23-25(dry base) | Conversion kiln: φ4.3×68m, with three-stage preheater.

Conversion cooling machine: φ3.8×40m(spray water) or grate cooling machine | Acidizing kiln: hot blast furnace with inner jacket φ3.5×50m.

Acidizing material cooling machine: φ3.5×50m(external water) | φ3.2x13m ball mill or

ZKRM19.3 vertical mill |

| Industrial grade lithium carbonate | 1764 |

Anhydrous lithium hydroxide (OH)

Li > = 56.5%) (OH) | 10000 |

| Anhydrous sodium sulfate (Li₂O 0.1%) to take away | 48550 |

| Leaching residue (Li₂O 0.3%) | 210000 |

| Lepidolite is the raw material |

| Product | Annual production of lithium carbonate (t/a) | Mixing volume (about 60% lepidolite)(t/h) | Host equipment type |

| Rotary kiln | Cooling machine | Ball mill |

| Lithium carbonate | 3000 | 15-18 | φ3.5×60m | φ2.5×23m | φ1.83×6.4m |

| Lithium carbonate | 5000 | 25-30 | φ4.2×72m | φ3×45m | φ3.2×13m |