The lollipop production line includes the casting lollipop production line and the stamping lollipop production line

1.Lollipop die production line

Fully automatic punching and die lollipop production line

Spherical lollipop production line

Special-shaped lollipop production line

Wavy candy/cane candy production line

2. Lollipop casting production line

Fully automatic lollipop casting production line

Fully automatic servo-controlled stick candy pouring production line

Fully automatic servo-controlled flat lollipop casting production line

Fully automatic servo planet lollipop casting production line

3. Lollipop types (candy shapes) and applications

4. Working Principle of Lollipop Machine

5. Installation of the lollipop production line

1. Fully automatic lollipop die production line

This production line can produce various types of die-cut hard candies.

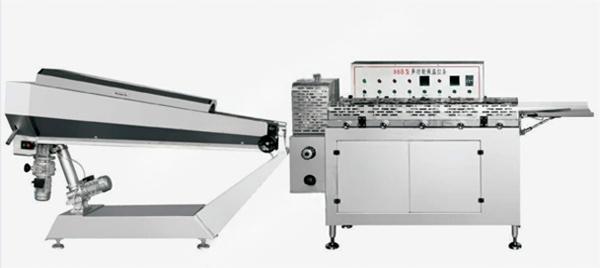

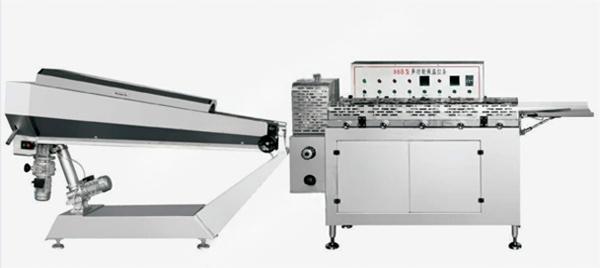

Fully automatic lollipop die production line

Technical parameters

Output :150-1200kg/h

Speed :120-1800Pc/min

Maximum sugar weight :16g

Minimum sugar weight :2g

Steam pressure :0.5-0.8Mpa

Steam consumption :150-600kg/h

Working environment requirements: Room temperature :20-25℃, Humidity :55%

Power :12-60KW/380V

Length :16m-26

Weight :4000kg-11000kg

The lollipop die production line can produce lollipops of different shapes by changing molds, with a production capacity of 50-1200kg/h. If your factory needs to produce a large number of lollipops of different shapes, then the lollipop die production line is your choice. The lollipop die production line adopts an electrically heated boiling pot, with PLC controlling the heating time and temperature, ensuring the transparency and taste of the sugar. Equipped with a lollipop punching machine, it can reduce the generation of waste materials and save you more costs. We have rich experience in manufacturing candy production lines. We can not only customize candy production lines according to your needs, but also provide you with corresponding molds.

The processing flow of the fully automatic lollipop die stamping production line

Sugar dissolving pot - Sugar storage tank - Vacuum continuous sugar boiling pot - cooling table - Heat preservation roller bed - Homogenizing machine - Die forming machine - shaking head distributor - Cold cabinet - packaging machine

Machine characteristics

The vacuum sugar boiling temperature, time, pouring temperature and pouring speed are controlled by computer

The 10.7-inch touch screen displays the process flow chart, the working status of each part, as well as parameters such as temperature and pouring speed

Variable frequency speed regulation controls the accurate flow rate of sugar liquid, ensuring stable quality of sugar paste

Candies of various shapes can be produced according to different molds

By replacing some devices and molds, this production line can produce spherical, flat and three-dimensional lollipops

Easy to operate and maintain

Non-standard machines can be customized according to the site requirements of customers

Spherical lollipop production line

The production process of spherical lollipops

Sugar dissolving - storage tank - Vacuum boiling pot - cooling table - Insulated rolling bed - Pulling machine - Spherical lollipop forming machine - Cooling cabinet - packaging machine

Special-shaped lollipop production line

The process flow of the special-shaped lollipop production line

Sugar dissolving - storage tank - Vacuum boiling pot - cooling table - Insulated rolling bed - Pulling machine - Irregular lollipop forming machine - Conveyor belt - packaging machine

Wavy candy/cane candy production line

The process flow of the special-shaped lollipop production line

Sugar dissolving - storage tank - Vacuum boiling pot - cooling table - Insulated rolling bed - Stretching machine - Creasing machine - New type of special-shaped lollipop forming machine - Cane candy machine - Conveyor belt - packaging machine

Main equipment

Vacuum continuous boiling pot

It has the functions of automatic sugar boiling and automatic temperature control, with high output, fast sugar boiling speed, and the syrup produced has high transparency

①. Sugar dissolving pot

Capacity (L):300

Weight (kg):280

Overall dimensions (mm):1100*1100*1700

②. Sugar storage tank

Capacity (L):300

Weight (kg):220

Overall dimensions (mm):740*740*1250

③. Technical parameters

Production capacity (kg/h):350-400

Heating area (m³):2.45

Steam pressure (MPa):0.7-1.0

Steam consumption (kg/h): approximately 100

Sugar solution entry temperature (°C):110-115

Discharge temperature (°C):135-145

Power - fixed displacement pump (kw):0.75

Matching power - Vacuum pump (kw):5.5

Overall dimensions (mm):1900*1700*2300

Overall weight (kg):800

Insulated roller bed drawing machine

Usage: Suitable for keeping sugar paste warm and pulling it into strips.

Features: Simple operation, labor-saving, and high efficiency.

Technical parameters

The maximum capacity of the roller bed (m³) : 0.20

Extrusion speed (m/min):≤40

Total power (kw):7

Weight (kg):850

Overall dimensions (mm): Four wheels :4270*890*1700

Overall dimensions (mm): Five wheels :4525*890*1700

Candy forming machine

Application: It is suitable for the production of irregular-shaped lollies, such as flat round, oval, large foot board and cartoon irregular-shaped lollies (shapes can be customized according to customer requirements).

Features: It adopts top pressure stamping forming, which is simple to operate, highly efficient and labor-saving.

Technical parameters

Production capacity: 150-250pcs/min

Finished product weight: 10-20g per piece

Total power: 2.5kw

Weight: 1550kg

Overall dimensions: 1950x860x1640mm

Extruder

Technical parameters

Production capacity (kg/h):200-300

Total power (kw):11

Overall dimensions (mm):1380x500x1480

Machine weight (kg):1100

Lollipop cooler

The candy cooling tunnel is a highly efficient and energy-saving rapid cooling equipment specially designed for candy cooling. It has the characteristics of good cooling effect, high speed and low noise. This type of candy cooling equipment cools and conveys candies by the vibration mode of the CAM crank arm swinging left and right. Therefore, during the cooling and conveying process, it provides a more uniform cooling effect for the candies, preventing them from changing and cracking during the cooling process. Meanwhile, the swinging vibration mode effectively prevents the candies from adhering to each other and sticking to the swinging disc. The closed and silent design complies with environmental protection standards and is a cooling equipment suitable for the production line of candy stamping.

Fully automatic spherical candy twisting packaging machine

Purpose

Suitable for twisted packaging of spherical lollipops.

Characteristics

The automatic sugar processing feeding device is aesthetically pleasing in style, low in noise, stable in operation and convenient for maintenance.

An AC motor is equipped with a frequency converter to achieve variable speed control

Fully automatic computer control, photoelectric color mark tracking.

Photoelectric sensor detection, bidirectional tracking, featuring fast tracking, accurate patterns, and effective elimination of packaging errors.

Food contact components are made of stainless steel, which is easy to clean and meets hygiene requirements.

Irregular-shaped candy twisting packaging machine

Uses and Characteristics

It adopts a numerical control display screen, which is convenient and intuitive to operate. The system control is stable and any parameters can be adjusted without stopping the machine. It adopts an electronic film pulling system for smoother speed and an independent temperature control system. Material sorting, tape making, sealing and cutting, knotting and packaging are completed.

2. Lollipop casting production line

Fully automatic lollipop casting production line

The lollipop casting production line can produce lollipops in various colors and can offer layering and striped options for spherical and bicolor spherical shapes. Compared with the die production line, the candy produced by the casting production line has a smoother surface and saves more labor. It is suitable for manufacturers that need to produce lollipops in large quantities. The continuous candy casting production line is mainly used for the casting production equipment of candy. This equipment integrates mechanics, electricity, steam and automatic control. It features high-quality candies, a wide variety of types, simple operation, compact structure and high degree of automation. The continuous lollipop casting production line can not only produce single-color lollipops, spray-painted lollipops, and filled lollipops, but also, by adding casting heads, produce a variety of colored and flavored products such as double-ball connected lollipops.

Technical parameters:

Output (10g) : 150kg-1200/h

Power :16kw-58kw

Compressed air consumption :0.5m ³ /min

Compressed air pressure :0.4-0.6Mpa

Steam consumption :250-1200kg/h

Steam pressure :0.6-0.8Mpa

Water consumption :2200L/h

The overall length of the machine is 17-50mm

Weight :4000-12000kgs

Because the lollipops produced by this unit have the characteristics of clear spray stripes, accurate filling amount and filling position, and good taste, they are popular among many users.

Technical parameters:

Output (10g) : 150kg-1200/h

Power :16kw-58kw

Compressed air consumption :0.5m ³ /min

Compressed air pressure :0.4-0.6Mpa

Steam consumption :250-1200kg/h

Steam pressure :0.6-0.8Mpa

Water consumption :2200L/h

The overall length of the machine is 17-50mm

Weight :4000-12000kgs

This production line is composed of sugar boiling POTS, sugar storage tanks, vacuum film sugar boiling machines, pouring machines, molds, cold storage cabinets and other parts. This production line can produce two-color spray-painted, two-color double-layer, single-color, and sandwich lollipops. Customers can produce various cast lollipops by changing the molds.

This production line is programmed by PLC to control the vacuum sugar boiling, conveying and pouring programs. It can complete the quantitative injection of liquid flavors, pigments and acid solutions online. This machine is equipped with a stable and reliable automatic rod insertion and placement device. The entire production line is finely designed with a compact structure and reliable performance.

Features:

1. It adopts Mitsubishi's PLC system to automatically control the time, temperature, pouring speed and pouring temperature of sugar boiling

2. The 10.7-inch touch screen can display the working status, temperature, pouring speed and other parameters of each part of the production line

3. Variable frequency speed regulation is adopted to control the flow rate of the syrup to ensure the quality of the produced products

4. Lollipops of various shapes can be produced according to different molds

5. The optional chocolate quantitative filling system can produce chocolate filled lollipops

6. By replacing some devices and molds, this production line can produce hard candies

7. Non-standard machines can be customized according to the customer's site requirements

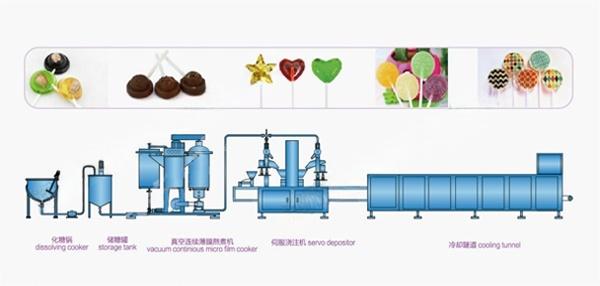

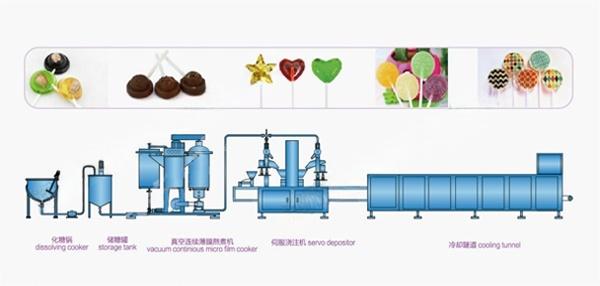

The process flow of the fully automatic lollipop casting production line

Fully automatic servo-controlled stick candy pouring production line

The fully automatic PLC-controlled vacuum film continuous sugar boiling and candy casting forming production line is a production equipment for casting candy. This machine integrates mechanical, electrical and pneumatic control. It has a reasonable and compact structure and a high degree of automation. It features high production efficiency and is capable of manufacturing single-color, double-flavor and double-color spray-painted, double-flavor and double-color double-layer, three-flavor and three-color spray-painted, four-color and four-flavor products, as well as crystal candies, filled candies, striped candies, sugar-free xylitol sticks and thinking magic sticks, etc.

This machine is equipped with an automatic stick insertion system, which enables the entire line to operate automatically, making the operation simpler and more convenient. In addition, this production line also has the same characteristics as the hard candy casting production line; The lollipop casting production line and the hard candy casting production line can be interchanged by replacing the molds and some devices.

Model :ZY1200B-S

Output :1200kg/h

Candy weight: According to the size specified by the customer

Pouring speed :30-60n/min

Steam demand :1200kg/h,0.5-0.8MPa

Compressed air demand :0.6m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%.

Overall power :56kw/380v

The overall length of the machine is 40 meters

Total weight of the whole machine: 12,000 kg

Model :ZY600B-S

Output :600kg/h

Candy weight: According to the size specified by the customer

Pouring speed :25-35n/min

Steam requirement :500kg/h,0.5-0.8MPa

Compressed air demand :0.3m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%.

Overall power :38kw/380v

The overall length of the machine is 22 meters

Total weight of the whole machine :7000kg

Model :ZY450B-S

Output :450kg/h

Candy weight: According to the size specified by the customer

Pouring speed :25-35n/min

Steam demand :400kg/h,0.5-0.8MPa

Compressed air demand :0.25m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%.

Overall power :34kw/380v

The overall length of the machine is 19 meters

Total weight of the whole machine :6000kg

Model :ZY300B-S

Output :300kg/h

Candy weight: According to the size specified by the customer

Pouring speed :25-35n/min

Steam requirement :300kg/h,0.5-0.8MPa

Compressed air demand :0.2m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%.

Overall power :27kw/380v

The overall length of the machine is 19 meters

Total weight of the whole machine :5000kg

Model :ZY150B-S

Output :150kg/h

Candy weight: According to the size specified by the customer

Pouring speed :25-35n/min

Steam demand :250kg/h,0.5-0.8MPa

Compressed air demand :0.2m³/min,0.4-0.6MPa

Working environment requirements: Temperature 20-25°C; Humidity: 45-55%.

Overall power :18kw/380v

The overall length of the machine is 17 meters

Total weight of the whole machine :4000kg

The process flow of the servo hard candy casting production line

Automatic weighing supporting system - Sugar dissolving - storage tank - Vacuum film boiling machine - servo casting machine - cooling tunnel - demolding - conveying - packaging - finished product

Fully automatic servo-controlled flat lollipop casting production line

Fully automatic servo-controlled flat lollipop casting production line

Model :ZY150P

Output :150kg/h

The weight of the lollipop: Depending on the size of the sugar shape

Pouring speed :25-55n/min

Steam requirement :250kg/h, 0.5-0.8MPa

Demand for concentrated air :0.2m ³ /min, 0.4-0.6MPa

Overall power :18kW/380V

The total length of the line :17 meters

The total weight of the machine is 4000kg

Model :ZY300P

Output :300kg/h

The weight of the lollipop: Depending on the size of the sugar shape

Pouring speed :25-55n/min

Steam requirement :300kg/h, 0.5-0.8MPa

Demand for concentrated air :0.3m ³ /min, 0.4-0.6MPa

Overall power :27kW/380V

The total length of the line :19 meters

The total weight of the machine is 5000kg

Fully automatic servo planet lollipop casting production lineb

Fully automatic servo planet Lollipop casting production line (three-dimensional lollipop production line)

Model :ZY150H

Production capacity :120-750kg/h

Sugar grain weight :5-40g per grain

Gas consumption :0.3m ³ /min,0.4-0.6mpa

Steam consumption :450kg/h

The external dimensions of the machine are 21*0.9*2.6m

The total weight of the machine is 4000kg

The ZY150H three-dimensional candy production line is a process-oriented candy production equipment. It is suitable for large-grained candies and can not only produce semi-three-dimensional and fully three-dimensional shaped candies, but also hand-molded candies. It can produce single-color, top-bottom, left-right dual-color and dual-flavor stick candies, as well as spray-painted stick candies. This machine integrates mechanics, electricity and pneumatics. It eliminates the CAM structure, has a compact structure and is equipped with an automated candy production device.

Machines are the components of the production line

Vacuum continuous film boiling machine

It has the functions of automatic sugar boiling and automatic temperature control, with high output, fast sugar boiling speed, and the syrup produced has high transparency

Mold

Customers can put forward their own design concepts, and we will complete the mold drawings. During the operation of the machine, just by changing different molds, the required lollipops can be produced

Pouring machine

This machine is composed of three parts: the pouring head, the mold and the cold cabinet. A standard pouring head is equipped with a double hopper. Customers only need to replace the distribution plate and nozzle to produce filled lollipops and two-color lollipops.

This machine is controlled by a PLC system, and parameters such as temperature and pouring speed can all be controlled on the touch screen. Meanwhile, variable frequency speed regulation is adopted to control the accurate flow rate of the sugar liquid, ensuring the stability of the sugar paste quality.

Chocolate filling device

Adding this device can produce lollipops with chocolate fillings. The storage cylinder is double-layered, and the insulation layer in the middle can ensure that the chocolate does not solidify

Packaging system

Candies are a type of candy with low water content and can easily absorb external moisture. After absorbing moisture, the product breaks up and becomes sandy again. Thus, the value of the commodity is reduced or lost. Therefore, packaging serves as a protective measure for candies, and its role lies in preventing or delaying the phenomenon of qualitative change. A reasonable approach is to seal the boiled candies. When the hard candies are isolated from the outside air, even after being stored for several years, it is not easy to notice any changes in quality.

3. Lollipop types (candy shapes) and applications

It is suitable for casting and punching out lollipops of different shapes

4. Working Principle of Lollipop Machine

Lollipop casting molding: conveyor belt, model tray, sugar injection nozzle, sugar pouring pump, storage tank, cooling device. Casting mold forming can produce lollipops. During the casting mold forming process, when the boiled sugar paste is still in an active state, the liquid sugar paste is quantitatively injected into the continuously running lollipop mold tray, then rapidly cooled and set, and then separated from the mold tray and sent to the packaging machine along the conveyor belt for packaging.

Stamping lollipop forming: When the sugar dough cools to an appropriate temperature, stamping forming can be carried out. If the temperature is too high, the sugar body will be too soft and difficult to shape. Even if sugar blocks are formed, they are prone to sticking together or deforming. If the temperature is too low, the sugar dough will be too hard, and the formed sugar grains are prone to fuzz, darkening, and missing edges and corners. The suitable temperature for stamping forming is 80-70℃. At this temperature, the sugar dough is malleable. Stamping forming takes advantage of the characteristics of the sugar dough at this temperature range. The sugar dough is stretched into strips by a drawing machine or manually and then sent into the forming machine for stamping forming.

5. Installation of the lollipop production line

We will send engineers to help you install the machine