Phosphate ore pelletizing production line

As a strategic mineral of restricted exploitation in our country, phosphate rock's ore taste is also decreasing year by year. The reduction of ore taste leads to a significant increase in the cost of electricity consumption in yellow phosphorus production. The machine pelletizing process of Zhengmine will make the powder ore produced in the process of phosphate mining and yellow phosphorus production and the phosphorus concentrate pelletized to meet the pellet strength and particle size required for the production of yellow phosphorus electric furnace, further reduce the comprehensive cost of yellow phosphorus production and improve the utilization rate of phosphate ore.

Capacity: 100,000 t/a, 200,000 t/a

Ball diameter: 10mm~40mm

Strength: 1000N~4000N

Equipment configuration: ball mill, efficient clean strong granulator, pot granulator, drying equipment

Outstanding advantage

1, The phosphate powder and phosphorus concentrate powder are made into pellets, which improves the comprehensive utilization rate of phosphate rock;

2, The diameter of the ball is 10~40mm, the size is convenient to adjust, and the sphericity is good;

3, The pelletizing process only adds water, does not add binder, low production cost;

4, After drying and calcination, the strength of the ball is high, up to 1~4kN, and the transfer is not easy to break.

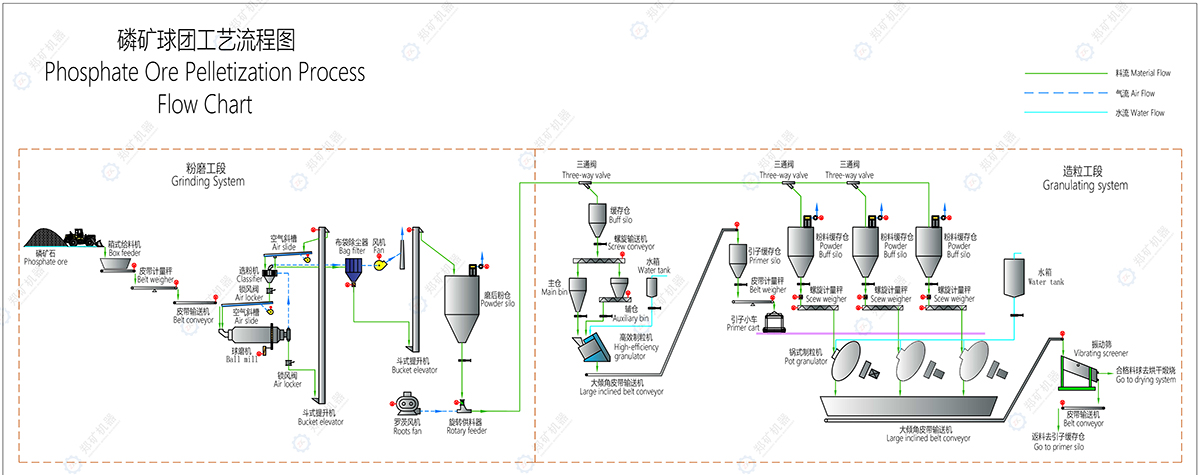

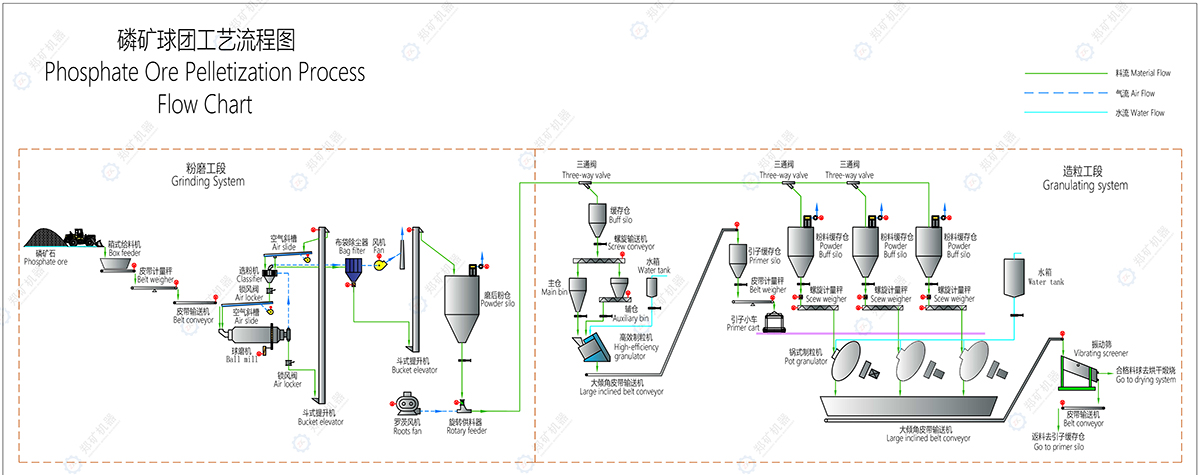

Process flow

1, Grinding system: phosphate rock powder (0~8mm), phosphorus fine powder through the box feeder, belt scale, belt conveyor ball mill grinding to 200~600 mesh, through the air selection of qualified fine powder and bag dust collector collection, qualified fine powder through the elevator into the grinding powder storage, coarse powder returned to the mill and then ground.

2. Pelletizing system: After grinding, the fine powder is sent to the ball making powder bin through the pneumatic conveying device. First, the lead of 2~5mm is made by adding less material water to the high efficiency granulator. Then it is sent to the lead slow storage bin through the high Angle belt conveyor. The raw material ball is sifted through the vibrating screen, the large ball is sent to the material ball drying system, and the ball under the screen returns to the storage bin as a guide to re-enter the pot granulator to make balls.

3, Drying system: the ball is dried by tunnel kiln, the ball is placed in the Saggar, the Saggar loading and unloading vehicles are automatically operated by robots, the drying heat source can use the yellow phosphorus tail gas generated by the electric furnace, and the ball after drying and cooling is transported to the storage yard by the belt machine.

Technical features:

1. High pellet strength, no binder involved in the pelleting process, the pellet strength can be 1000N~4000N according to the project requirements, adapt to various complex yellow phosphorus production conditions, improve the production safety and stability of yellow phosphorus electric furnace;

2, The ball is a round ball, the conventional pellet diameter of 10~40mm(other sizes can also be met), a production line can produce pellets of different sizes, and does not rely on the mold to change the size of the ball, convenient for the user to change the size of the pellet according to the actual production situation, so that the yellow phosphorus production economic benefits to achieve better;

3, Drying and sintering process decomposition of carbonate, further improve the taste of phosphate ore pellets, reduce the cost of yellow phosphorus production power consumption;

4, According to the size of the raw material to choose whether to use the ball mill grinding, grinding phosphate ore powder or phosphorus concentrate, the mineral distribution after the ball is more uniform, help to improve the reduction reaction in the yellow phosphorus furnace, improve labor efficiency.