Phosphogypsum disposal resources

Phosphogypsum is an industrial by-product produced in the process of wet phosphoric acid production. Due to its high free phosphorus, fluorine and other impurities, direct discharge or accumulation will cause serious pollution to the environment. Our company R & D phosphogypsum resource comprehensive utilization technology, has a complete set of process technology and core equipment R & D and manufacturing capabilities, the entire production line advanced technology, can efficiently and environmentally friendly disposal of phosphogypsum, to achieve resource reuse, promote the development of green circular economy.

Annual output: 5-500,000 tons

Main equipment: phosphogypsum calcining kiln, gypsum mill, granulator, bag dust collector, bucket elevator, belt conveyor, etc

Calcination temperature: according to the process to determine

Outstanding advantage

1, environmental protection: phosphogypsum disposal can reduce the solubility of heavy metals and toxic substances in phosphogypsum, reduce environmental pollution.

2, Solid waste resources: phosphogypsum disposal can be used as building or roadbed materials, cement retarder, etc., has a wide range of application prospects.

3. Economic benefits: The implementation of phosphogypsum disposal process reduces the cost of raw materials and improves the added value and competitiveness of products.

4. Development opportunities: The support of environmental protection policies provides more development opportunities for enterprises.

5, pilot test support: After many research and development and experiments, our company has made technical research on phosphogypsum solid waste grinding, granulation, drying, calcination, etc., and is equipped with a pilot production workshop, which can be used for incoming material experiments and successfully put into production again.

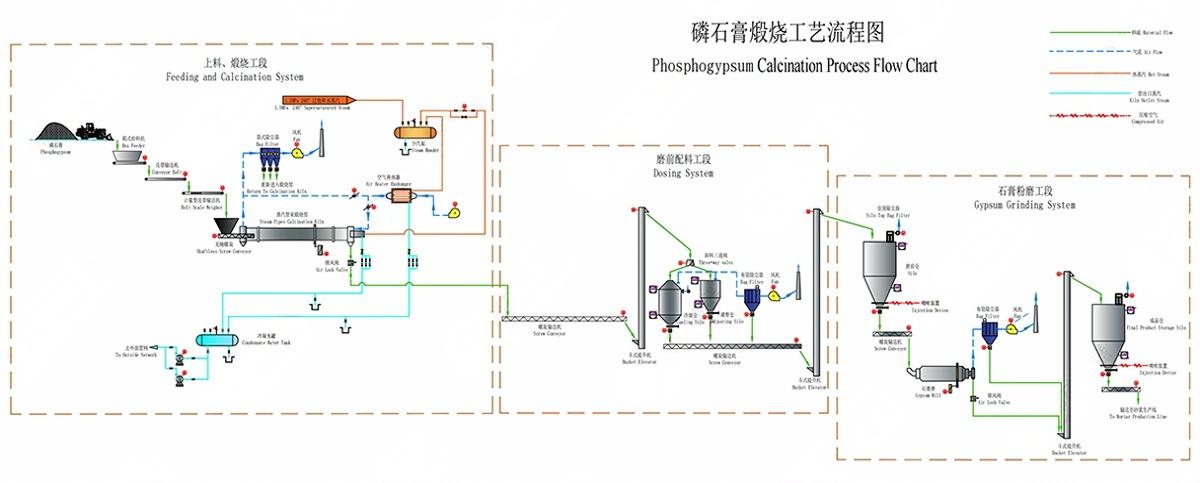

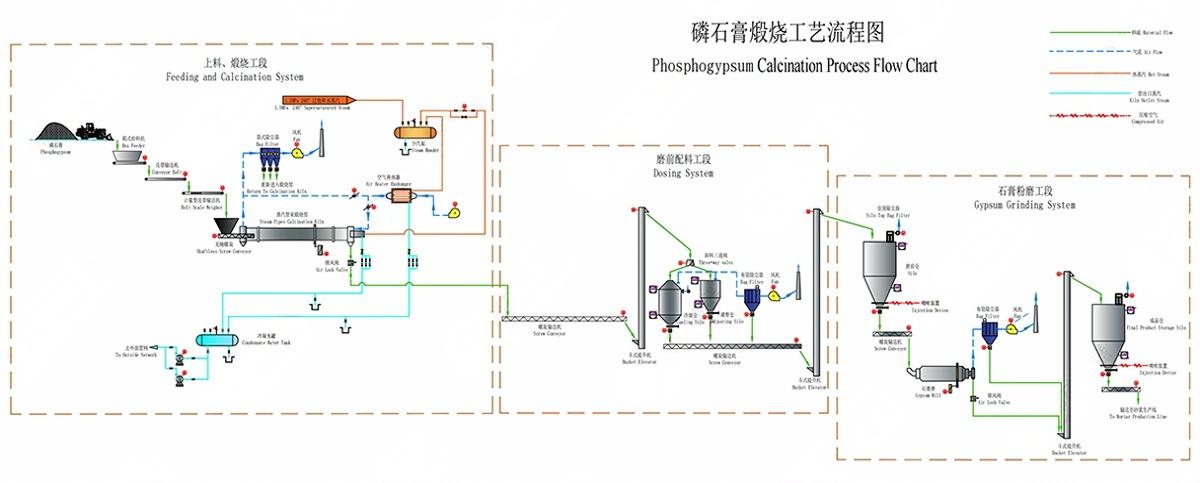

Process flow

(1) Charging calcining system

Phosphogypsum is fed by forklift to box feeder, and then transported to steam tube bundle calcining kiln by belt conveyor, metering belt and shafless screw, and calcined by 240℃ susaturated water steam. The calcined finished products go to grinding system, and the exhaust gas is discharged into the atmosphere by the exhaust fan chimney after dusting by the bag dust collector.

(2) pre-grinding batching system

The calcined material is sent into the cooling bin and adjusting bin through the screw conveyor and bucket elevator. The variable frequency feeding equipment is set under the bin. After adjusting the ratio, the material is sent into the pre-grinding bin through the screw conveyor and bucket elevator.

(3) Gypsum grinding system

Before grinding, there is a frequency conversion feeding device under the silo, and the gypsum powder is sent to the gypsum mill by screw conveyor. The ground material is sent to the finished silo by bucket elevator, and the discharge screw is set under the finished silo. Then, a packaging machine can be set up for packaging and selling or the powder material can be transported by bulk truck for export.

Technical parameter

| Typical production capacity main equipment configuration table |

| Annual production (tons) | 5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

| Main equipment | Main supporting equipment models and technical and economic indicators |

| Phosphorite has a rotary kiln | φ2.0×24m | D2.4×24m | D2.8×26m | φ3.0×26m | φ3.2×26m | φ3.4×28m | φ3.6×28m | ①4.0×28m |

| Phosphorite has a mill | φ1.2×4.5 | φ1.5×5.7 | Φ1.83×5.5 | φ2.1×6.5 | φ2.2×6.5 | φ2.4× 7 | φ2.4×8 | φ2.6×8 |

| Bag type dust collector | PPC96-6 | PPC96-8 | PPC128-6 | PPC128-9 | PPC96-2X9 | PPC128-2X7 | PPC128-2X9 | PPC128-2X12 |

| Raw material requirement | Calcium sulfate dihydrate content (dry base)≥90%,

Adhesion water content ≤15%

Water-soluble magnesium oxide (dry base)≤0.5%,

PH 6-8,

Chloride ion content (dry base)≤500mg/kg |

| Stage firing temperature /℃ | 150 |

| Steam energy consumption index /(kg/t stone powder) | 500±50 |

| Power consumption index /(kW h/t stone powder) | 25±5 |

| Phosphorus stone has: stone has powder | 1.4:1 |

| Setting time | Initial setting ≥8min,

Final setting ≤30 minutes |

| fineness | ≤5% |

| Strength (MPa) | 2-hour bending resistance ≥3.0MPa;

Compressive strength ≥6.5MPa; |

| Three-phase control | Dihydrite is less than 3%,

Hemihydrite is greater than 84%,

Soluble anhydrous stone is less than 3%; |

| Emission concentration /(mg/m) | ≤30 |

| Number of working days per year/day | ≥300 |

| Overhaul cycle/year | 3 |

| Suitable for heat source or fuel | Steam, natural gas, pulverized coal |