Phosphorus dressing production line

Phosphate ores can be divided into siliceous type, calcareous type, and siliceous (calcium) -calcium (silicon) type. Flotation method is the main mineral processing method of apatite. According to different phosphate rock properties, our company's design process mainly includes: flotation + magnetic separation process, grinding + classification + flotation process, stage grinding + stage separation process, roasting + digestion + classification process.

Outstanding advantage

The grade and recovery rate of phosphorus concentrate were improved by combined beneficiation process.

1, a wide range of applicable ores: can be applied to low-grade phosphate ores, including magmatic apatite and sedimentary metamorphic phosphate limestone ore.

2, energy saving economy: can achieve room temperature flotation, coarser product particle size in the tank is conducive to product post-processing, reduce costs.

3, environmental protection and no pollution: the use of alkali-free process, chemical pollution, will not cause harm to the environment and production.

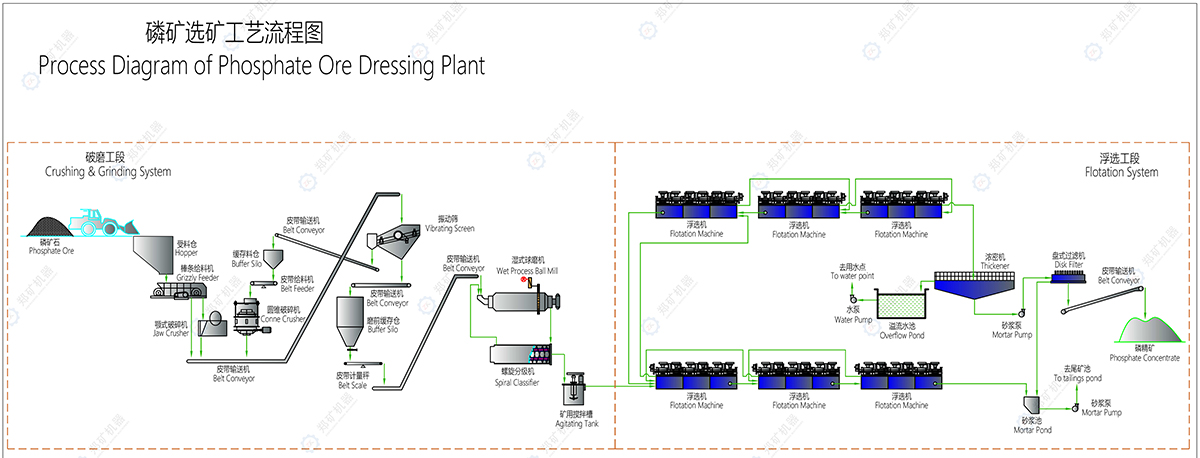

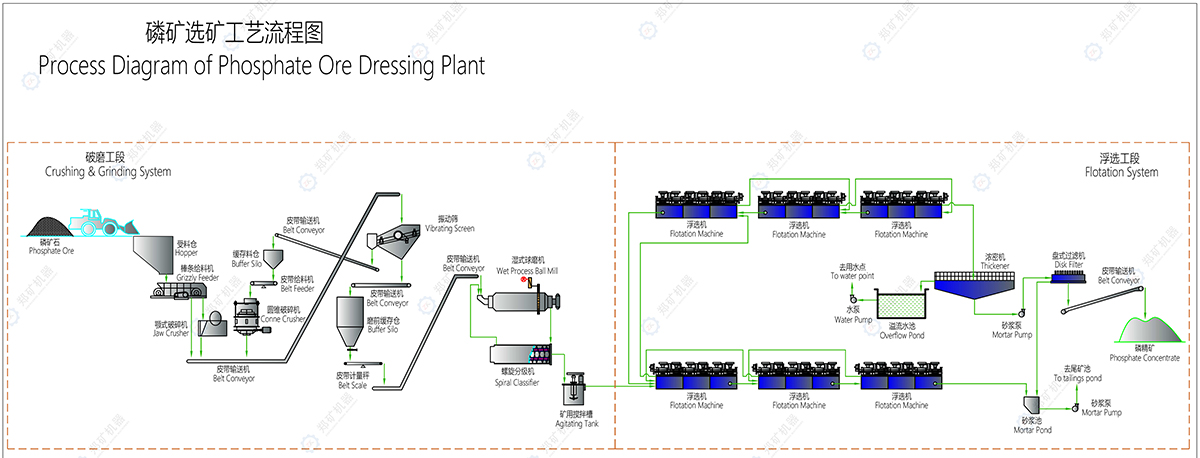

Process flow

In the extraction process of phosphorus, we need to break and grind large pieces of phosphate rock into fine powder, so in the process of mineral processing, you need to use two types of equipment, crusher and ball mill. After pulverizing phosphate rock, due to the relatively high floatability of phosphate rock, it also needs to be sorted by flotation machine, etc. It can be seen that the mineral processing process of phosphate rock mainly includes: crushing and screening, grinding, flotation, dehydration, tailings treatment several stages. Different stages of the processing process is different, the use of equipment is different, the following is to analyze these stages.

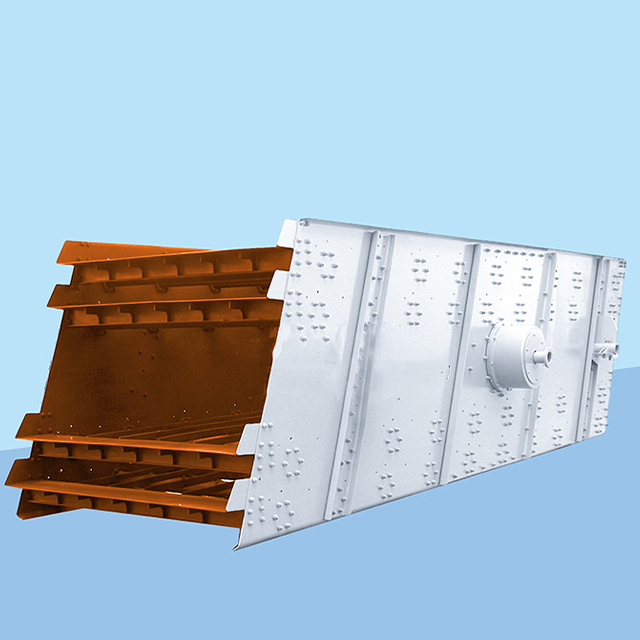

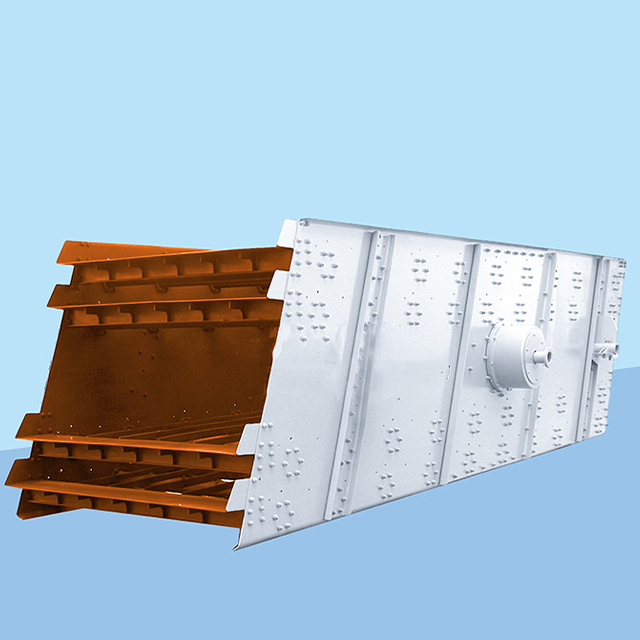

1, crushing and screening stages: This stage is mainly to break the bulk phosphate rock into small pieces, when broken, it is necessary to use two or three closed circuit process to break the bulk phosphate rock of 0-350 mm to small particles below 15 mm, and then to carry out the subsequent grinding operation, this stage of the screening operation, It is mainly to ensure that the crushed phosphate rock particles are uniform and meet the requirements below 15 mm;

2, grinding stage: the equipment used in this stage is mainly a ball mill, the last stage after crushing and screening of small pieces of phosphate rock by the feeder into the ball mill further grinding, this grinding process is also closed circuit grinding. This grinding process can grind small pieces of phosphate rock into a particle size of -200 purpose 75%, in order to enter the next production stage;

3, flotation stage: this stage uses a single reverse flotation process, after a rough selection, three times select, two sweep and ore return closed-circuit process, the obtained concentrate is pumped to the concentrate concentrator. There are three commonly used flotation separation methods at this stage: first, sodium silicate and starch are used to inhibit gangue minerals such as carbonate, and fatty acids are used as collector to flotation phosphate ores; The second is to add sodium hexametaphosphate to inhibit phosphate rock, float carbonate gangue mineral with fatty acid first, then float phosphate rock; Thirdly, selective alkyl sulfate is used as collector to first flotation carbonate minerals and then flotation phosphate minerals with oleic acid.

4, dehydration stage: this stage is mainly after flotation, need to go through two stages of dehydration: a high efficiency thickener dehydration, secondary dehydration using ceramic vacuum filter. These two stages of dehydration can reduce the water content of phosphate concentrate to less than 12%;

5, tailings treatment stage: the phosphate ore flotation process will produce tailings, which will be pumped to the tailings concentrator, and the underflow of the machine will be pumped to the tailings filling station. Then it can be recycled according to demand, which can avoid resource waste and environmental pollution.