Production process of pulverized coal ash ceramite production line

Fly ash is the waste discharged from thermal power plants, sludge can be the waste discharged from urban water treatment plants, or it can be the sludge at the bottom of rivers and lakes. After mixing and aging of fly ash, sludge and clay, building ceramics can be granulated and fired.

Introduction to production line of pulverized coal ash ceramite

1, the use of solid waste production of ceramics, not only can replace clay burning pottery, save land, waste into treasure, while high temperature sterilization, solidification of heavy metals, to avoid environmental pollution.

2, from the overall project planning to the detailed process formula, process design, equipment design and manufacturing, engineering installation, commissioning, etc. to provide a complete whole industry chain services, with a complete solid and dangerous waste treatment system solutions.

3. The company's pilot test line can carry out raw material analysis, formulation design, sample preparation, roasting, pilot test and pilot test of various sludge ceramics.

Main equipment: plug-in rotary kiln, single barrel cooling machine, double shaft mixer, granulator, bag dust collector, belt machine, etc

Ceramide production capacity: 5-600,000 square meters/year

Specification: preheating kiln Φ 18 (m), Φ 1.55 x 1.25 x 1.8 x 20 (m), Φ 22 (m), 2 x 24 Φ (m), 3 x 20 Φ (m), Φ 2.5 x 12 (m)

Burning kiln specifications: Φ 1.6 x 14 (m), 1.9 x 16 Φ (m), 2.2 x 18 Φ (m), 2.5 x 20 Φ (m), 3 x 22 Φ (m)

Calcination temperature: 1100-1200℃

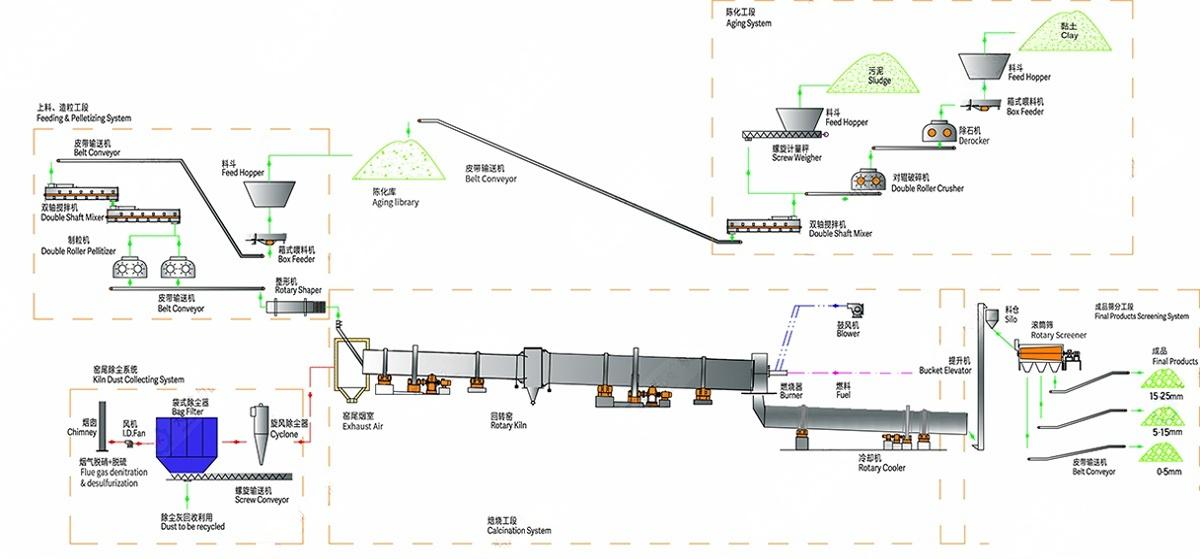

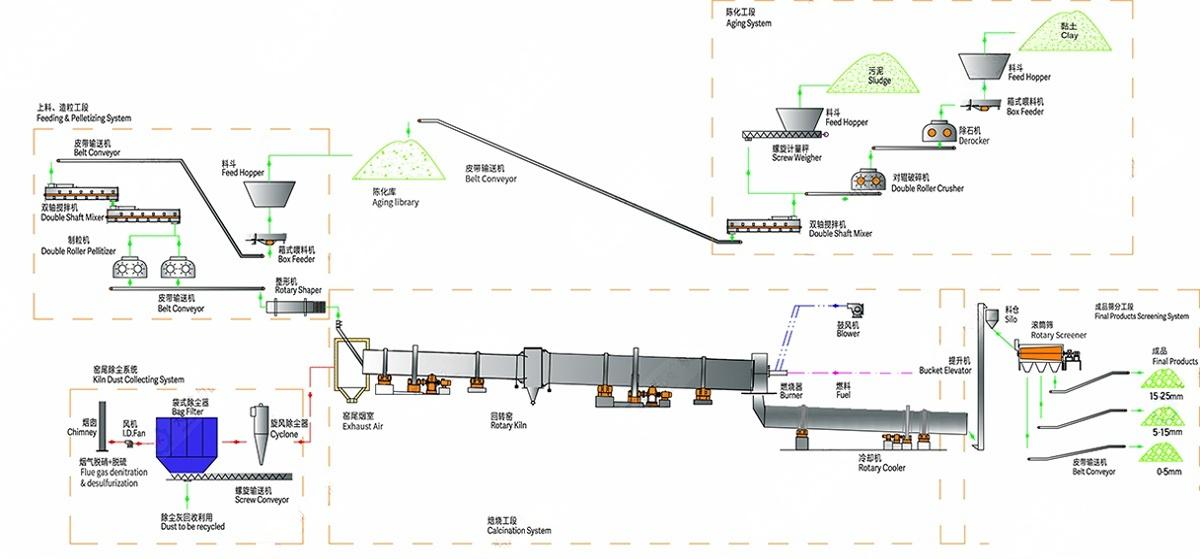

Process flow

Fly ash sludge ceramisite using fly ash, sludge and clay ingredients. The fly ash is stored in the round bin, discharged by the rigid impeller feeder under the bin, measured by the belt weigher, and fed into the double-shaft mixer; The sludge into the plant is piled in the awning, stored for a period of time to evaporate part of the water, is sent to the sludge bin by the forklift, and is also sent to the double-shaft mixer through the screw conveyor under the bin. The incoming clay is fed to the roller crusher through the box feeder and, after crushing, into the double-shaft mixer. Fly ash, sludge and clay are fully stirred in a double-shaft mixer, mixed evenly, and sent to the aging yard. The aging time is 7 ~ 15 days, and then the forklift is sent to the double-shaft mixer for dispersing and mixing, and then it is sent to the roller granulator. The granular material balls created are sent to the shaping screen machine by the belt conveyor. After the round treatment, the small particles are screened out, and the qualified pellet balls are sent to the double-barrel insert rotary kiln for preheating and roasting. After the fired ceramic products fall into the cooling machine to cool, the finished products of different particle sizes are divided by the rotary screen, respectively stored in the storage yard, bagged and shipped. The high temperature secondary air generated by the cooling machine enters the rotary kiln to assist combustion, which can save fuel. The fuel is sent to the rotary kiln by the high pressure fan through the multi-channel burner for combustion. The high temperature flue gas containing dust at the end of the kiln enters the air cooler to cool down, and then enters the bag dust collector to purify and empty.

Coal ash ceramic production line process flow

| Production capacity and host equipment parameters of sludge ceramite production line |

No.

| Device name | Sludge ceramide production line scale and equipment specifications |

| 15000 m²/a | 25000 m²/a | 35000 m/a | 50000 m³/a | 100000 m³/a |

| 1 | Roll crusher | 2PGC450*500 | 2PGC450*500 | 2PGC600×750 | 2PGC600×750 | 2PGC900*900 |

| 2 | Double shaft mixer | ZJ300 | ZJ400 | ZJ500 | ZJ600 | ZJ650 |

| 3 | Roller granulator | GL600×500 | GL700*600 | GL800*700 | GL800*7002台 | GL800×7004台 |

| 4 | Plug rotary kiln | Preheating kiln Φ1.25*18m | Preheating kiln

Φ1.55-20m | Preheating kiln

Φ1.8-22m | Preheating kiln

φ2*24m | Preheating kiln

φ3*20m/φ2.5*12m |

| Roasting kiln φ1.6*14m | Calcining kiln

Φ1.9×16m | Calcining kiln

φ22*18m | Calcining kiln

①2.5*20m | Calcining kiln

φ3*22m |

| 5 | Single cylinder cooling machine | φ1.2*12m | φ1.5*15m | φ1.8×18m | φ2*20m | φ2.2*22m |

| 6 | Vertical cooler | 一 | 一 | LSF26 | LSF36 | LSF36 |

| 7 | Air cooler | 50m² | 80m² | 120m² | 200m² | 400m² |

| 8 | Bag dust collector | PPC32-3 | PPC32-5 | PPC64-4 | PPC64-5 | PPC96-5 |

| 9 | Air blower | 5633m°/h 15kW | 8294m²/h 22kW | 12213m³/h 22kW | 16099m²/h 37kW | 33309m³/h 75kW |

| 10 | Rotary screen | φ600=2900mm | φ800=3600mm | ①900*4200mm | φ1100*4500mm | φ1500*6000mm |

| 11 | Belt conveyor | More than B500 |

| The main configuration of different scale sludge ceramite production lines |

Ceramide productivity host parameters | Annual output | 15000m³/a | 25000m²/a | 35000m²/a | 50000m³/a | 100000m³/a |

| Plug-in rotary kiln | Specification | Preheating kiln | φ1.25*18m | φ1.55*20m | φ1.8*22m | φ2=24m | ①3×20m/φ2.5×12m |

| Calcining kiln | Φ1.6*14m | φ1.9×16m | φ2.2*18m | φ2.5*20m | φ3*22m |

| Output (m²/h) | 2.21-2.96 | 3.27-4.36 | 4.42-5.9 | 5.57-7.41 | 9.85-13.13 |

| Slope (%) | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 |

| Speed (r/min) | Preheating kiln | 1-5 | 1-5 | 1-5 | 1-3 | 1-5 |

| Calcining kiln | 1-5 | 1-5 | 1-5 | 1.2-3.6 | 0.9-2.7 |

| Calcination temperature (℃) | 1100-1200 |

Introduction of finished product of pulverized coal ash ceramite production line

Fly ash is the waste from thermal power plant. Sludge can be the waste discharged from urban water treatment plants, or it can be the sludge at the bottom of rivers and lakes. Fly ash and sludge, clay mixed after aging, can be pelleted and fired into building ceramics, so that solid waste can be effectively used, clay is only used as a binder, saving a lot of land, turning waste into treasure, solidifying heavy metals, to avoid pollution.