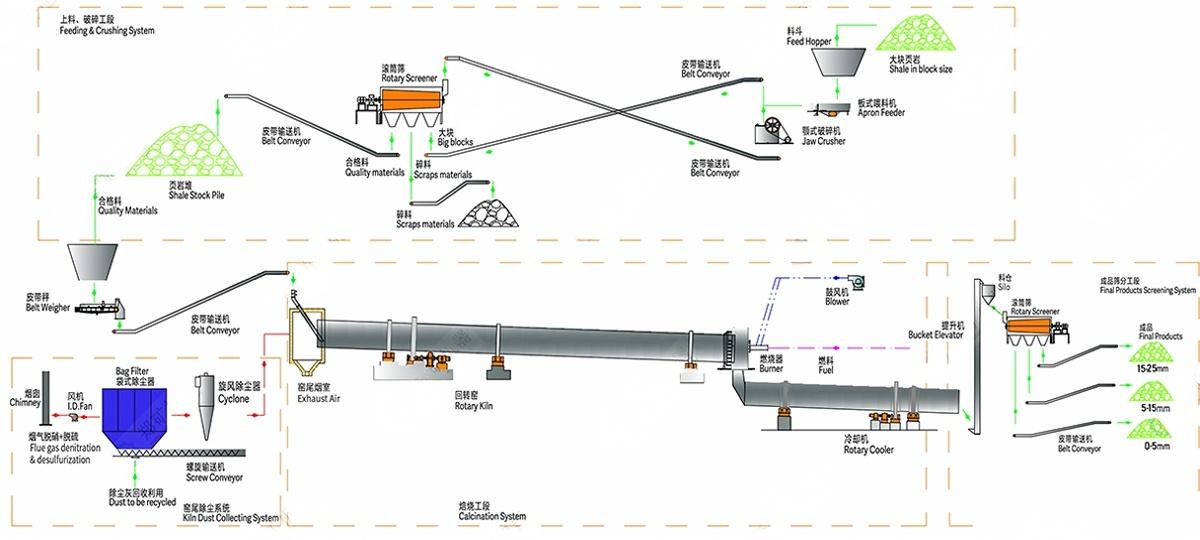

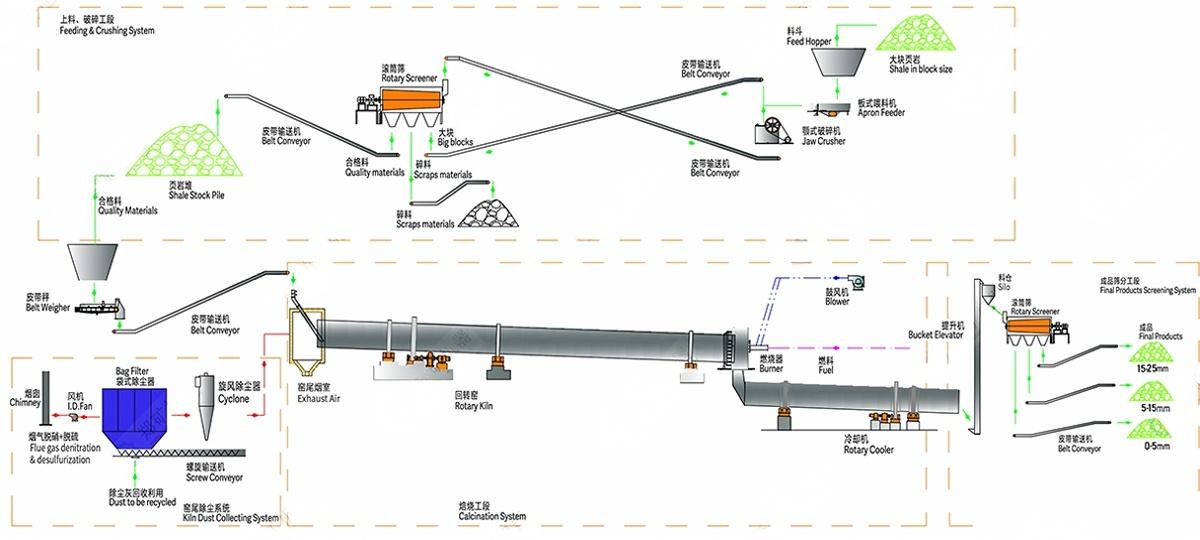

Production process of shale ceramisite production line

Introduction of shale ceramisite production line

Shale ceramisite is made from natural rock shale by crushing, screening, preheating and roasting. Its non-toxic, tasteless, pressure and wear resistance, corrosion resistance, and has good adsorption properties and strength, its material light, pressure resistance, heat preservation, antifreeze, shock-proof, no radiation advantages, suitable for building energy saving materials, but also used for all kinds of water purification treatment and flower bonsai soilless cultivation. After years of research, Zhengkuang Machinery has developed energy saving and environmental protection equipment suitable for the use of ceramite generation line, which opens up a new process route for the construction of new environmental protection and energy saving ceramite.

Production line advantages:

1. Experimental analysis: The company's pilot test line can carry out raw material analysis, formula design, sample preparation, roasting, pilot test and pilot test of various sludge ceramics;

2, conservation and environmental protection: save land, turn waste into treasure, and solidify heavy metals to avoid environmental pollution;

3, advanced process equipment: from the overall project planning to the detailed process formula, process design, equipment design and manufacturing, engineering installation, commissioning, etc. to provide a complete whole industry chain services, with a complete solid and dangerous waste treatment system solutions.

Introduction to the production process: The bulk shale is unloaded into the silo, sent to the jaw crusher by the plate feeder under the silo, and then sent to the rotary screen screening device by the belt conveyor, which is divided into large particles, qualified particles and broken particles. The large particles are returned to the crusher for re-crushing, the broken particles are piled up, and the qualified particles are sent to the pile shed for storage and use. The shale with qualified particle size is sent to the silo by forklift truck, and the belt weigher is set under the silo. After the shale is measured, it is sent to the single-barrel rotary kiln by belt conveyor for calcining. The shale is preheated and calcined in a rotary kiln to produce ceramide. Then the high-temperature ceramic particles fall into the cooling machine after cooling, and then the finished products of different particle sizes are divided by the rotary screen, respectively stored in the storage yard, bagged and shipped. The natural air cooling ceramic particles in the cooling machine is heated into the rotary kiln to assist combustion, which can save fuel. The fuel is sent to the rotary kiln by the high pressure fan through the multi-channel burner for combustion. The high temperature flue gas containing dust at the end of the kiln enters the air cooler to cool down, and then enters the bag dust collector to purify and empty.

Main equipment: ceramic rotary kiln, single barrel cooling machine, crusher, double shaft mixer, roll granulator, bag dust collector, belt machine, etc

Ceramide production capacity: 5-600,000 square meters/year

Specification: preheating kiln Φ 18 (m), Φ 1.55 x 1.25 x 1.8 x 20 (m), Φ 22 (m), 2 x 24 Φ (m), 3 x 20 Φ (m), Φ 2.5 x 12 (m)

Burning kiln specifications: Φ 1.6 x 14 (m), 1.9 x 16 Φ (m), 2.2 x 18 Φ (m), 2.5 x 20 Φ (m), 3 x 22 Φ (m)

Calcination temperature: 1100-1200℃

Shale ceramic production line process flow

| Production capacity and main equipment parameters of shale ceramite production line |

| NO. | Device name | Shale ceramisite production line scale and equipment specifications |

| 25,000 m²/a | 35,000 m³/a | 50,000 m³/a | 65,000 m³/a | 120,000 m³/a |

| 1 | Jaw crusher | PEX150*500 | PEX150*500 | PEX150*750 | PEX250×750 | PEX250×1000 |

| 2 | Single cylinder rotary kiln | Φ1.5*26m | Φ1.8*28m | ①2.2=30m | ①2.4*33m | φ2.6*28m |

| 3 | Single cylinder cooling machine | Φ1.2*12m | φ1.5×15m | φ1.8*18m | Φ2*20m | φ2.2*22m |

| 4 | Vertical cooler | 一 | 一 | LSF26 | LSF36 | LSF36 |

| 5 | Air cooler | 80 m | 120m² | 200 m | 280 m | 500 m |

| 6 | Bag dust collector | PPC32-5 | PPC64-4 | PPC64-5 | PPC64-7 | PPC96-7 |

| 7 | Air blower | 9-19No.9D | 9-19No.12.5D | 9-19No.12.5D | 9-19No.14D | 9-26No.14D |

| 8294m°h 22kW | 12213m°/h 22KW | 16099m²/h 37KW | 22618m²/h 75KW | 42897m²/h 110kW |

| 8 | Rotary screen | φ600=2900mm | φ800×3600mm | φ900×4200mm | Φ1100×4500mm | φ1500×6000mm |

| The main configuration of shale ceramite production lines of different sizes |

| Ceramide productivity host parameters | 25000 m³/a | 35000 m²/a | 50000 m²/a | 65000 m³/a | 120000 m³/a |

| Single cylinder rotary kiln | specification

| Φ1.5*26m | Φ1.8*28m | Φ2.2=30m | φ2.4×33m | Φ2.6*28+φ3*20m |

| yield | 3.21-3.85m²/h | 4.56-5.46m/h | 6.34-7.6m²/h | 8.32-9.99 m³/h | 14.68-17.62m³/h |

| slope |

| 3.5-4.0% |

| Speed (r/min) | 1.2-3.6 | 1.2-3.6 | 1.0-3.0 | 1.0-3.0 | 1.2-3.6 |

| Calcination temperature (℃) | 1100-1200 |

Introduction of finished product of shale ceramisite production line

Shale ceramisite is made from natural rock shale by crushing, screening, preheating and roasting. Its non-toxic, tasteless, pressure and wear resistance, corrosion resistance, and has good adsorption properties and strength, its material light, pressure resistance, heat preservation, antifreeze, shock-proof, no radiation advantages, suitable for building energy saving materials, but also used for all kinds of water purification treatment and flower bonsai soilless cultivation.