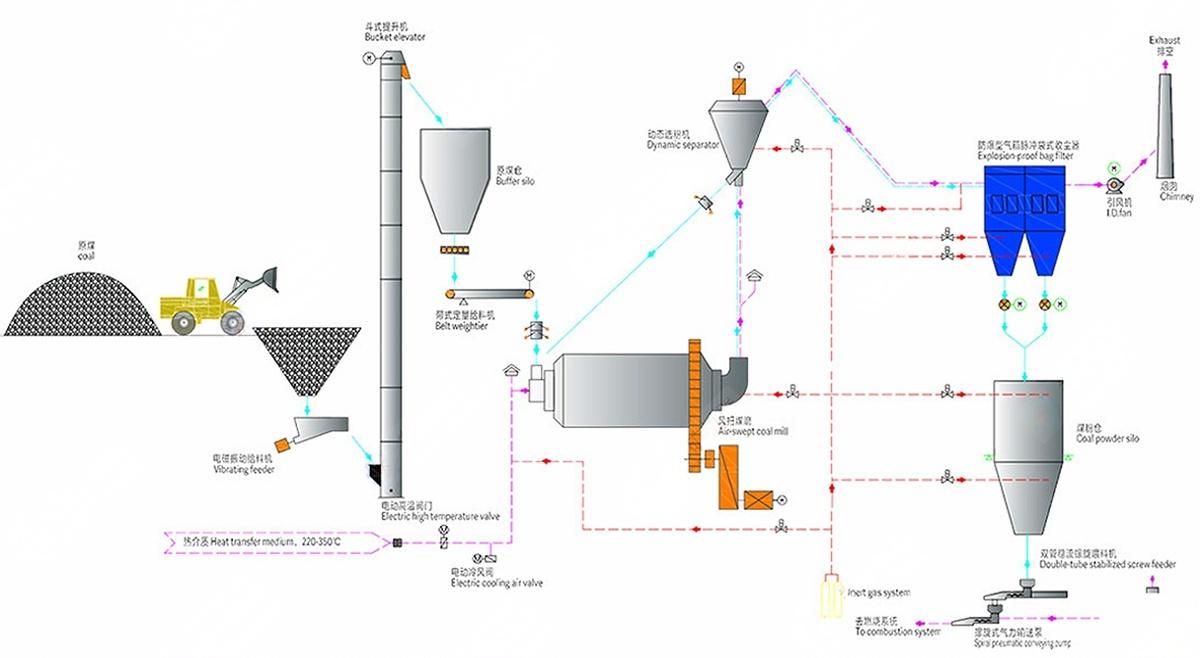

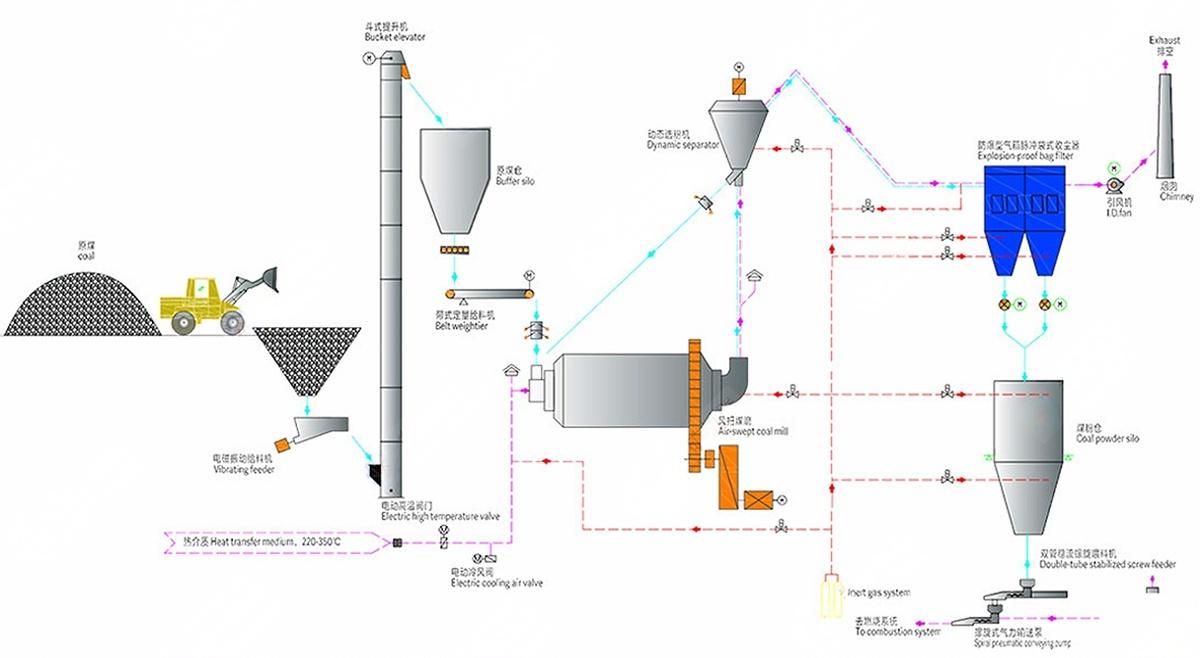

Pulverized coal preparation system

The project of our company's wind-swept pulverized coal preparation station is composed of raw coal storage and transportation system, pulverizing system, pulverizing system, electrical and instrument automation system. Blast relief valve and nitrogen protection interface are provided in the hot air inlet pipe and the coal air outlet pipe to protect the safety of equipment and system. The separator equipment adopts frequency conversion motor to speed regulation, and the fineness of powder can be controlled remotely by adjusting the frequency converter.

Capacity: 1-300,000 tons/year

Main equipment: air sweep mill, dynamic separator, explosion-proof dust collector

Equipment services: from raw material storage and transportation, pre-drying, grinding, powder selection, cooling to finished product storage and transportation system, environmental dust collection system, electrical automation control system process design, plant planning, equipment supply, equipment installation and commissioning, after-sales training and a series of technical services

Outstanding advantage

1, the auxiliary equipment is stable, reliable, energy saving as the principle, to ensure the normal production of high yield and low energy consumption;

2, fully combined with the local natural conditions, in order to meet the process production conditions, optimize the design scheme, as far as possible to reduce the project cost;

3. Strictly control environmental pollution, reduce pollutant emissions, protect and improve the environment, and achieve safe and civilized production.

Process flow

I, raw coal storage and transportation system

1. The raw coal with particle size < 35mm and water content < 15% is transported to the raw coal shed by the dump truck, the raw coal stored in the coal shed is loaded into the coal hopper by the loader, and the raw coal in the coal hopper is uniformly fed to the bucket elevator by the speed feeding belt machine, and the raw coal is discharged after the elevator is lifted to the required height, and enters the pulverizing system through the double lock air valve.

2. A bar valve is arranged between the receiving hopper and the vibrating feeder. The bar valve can be closed during the maintenance of the speed feeding belt conveyor, which is conducive to the maintenance operation. Speed feeding belt machine can realize speed control function, which is conducive to generating operation and management. The adjustable speed feeding belt is equipped with an iron remover, which can remove the iron filings doped in the raw coal and avoid the threat of iron filings to the system.

II, powder system

1, the raw coal storage and transportation system into the wind-swept coal mill, after grinding, coal and 200℃ ~ 350℃ hot air for mass and heat transfer, water from the coal into the flue gas, coal powder is dried by the hot air, and then, coal powder with the air into the sorting machine, the selected coarse powder back to the mill grinding, fine powder continues to flow through the coal air pipe into the powder collection system.

2, air sweep coal mill hot air inlet pipe and coal air outlet pipe are set with explosion valve and nitrogen protection interface, to protect the safety of equipment and system. By adjusting the frequency converter, the fineness of the powder can be controlled remotely.

III. Powder collection system

Under the negative pressure of the induced draft fan of explosion-proof bag dust collector, the qualified fineness of the pulverized coal discharged by the separator enters the explosion-proof bag dust collector through the coal air pipe. The pulverized coal is captured and falls into the pulverized coal bucket at the lower part of the dust collector. The filtered and purified flue gas is discharged to the atmosphere by the chimney of the induced draft fan. The pulverized coal stored in the pulverized coal hopper is sent to the pulverized coal bin by the star discharger and the screw conveyor.

Technical parameter

| Main equipment \ capacity (t/h) | 3 | 6 | 10 | 14 | 16 | 20 | 25 | 30 |

| Main supporting equipment models and technical and economic indicators |

|

| Belt dosing feeder | DEL-500 | DEL-500 | DEL-650 | DEL-650 | DEL-800 | DEL-800 | DEL-800 | DEL-1000 |

| Air swept coal mill (m) | φ1.7×2.5 | φφ2.2×3 | φ2.4×4.75 | φ2.6×5.25 | φ2.9×4.7 | φ3.2×4.7 | φ3.2×5.8 | φ3.5×6.0 |

| Barrel volume /m3 | 5.7 | 9.7 | 19.25 | 24.5 | 31 | 37.8 | 46.6 | 57.7 |

| Ball load /t | 7.5 | 13 | 22 | 30 | 35 | 44 | 55 | 64 |

| Power of air swept coal mill /kW | 95 | 180 | 280 | 400 | 560 | 710 | 900 | 1000 |

| Dynamic powder separator | MD200AP | MD200AP | MD350AP | MD500AP | MD700AP | MD700AP | MD850AP | MD1000AP |

| Separator power /kW | 11 | 11 | 18.5 | 18.5 | 22 | 22 | 30 | 45 |

| Fineness of pulverized coal R90 | ≤8% |

| Moisture content of pulverized coal | s2% |

| Hot air inlet temperature / ° C | 220-350 |

| Mill outlet air temperature /℃ | 60-70 |

| Emission concentration /(mg/Nm3) | 30 |

| Number of working days per year/day | 300 |

| Number of operators /(person/shift) |

|