Rotary kiln for lime

Product introduction: Lime rotary kiln is a new type of active lime special rotary kiln developed on the basis of absorbing and learning from the same type of rotary kiln at home and abroad for calcining characteristics of limestone.

Capacity: 150-1200t/d

Model: φ2.5×40-φ5.1×72m

Calcination temperature: 1100±50℃

Calcination heat sources: pulverized coal, coke oven gas, charcoal furnace gas, converter gas, blast furnace gas, calcium carbide furnace gas, natural gas, diesel oil, heavy oil, liquefied petroleum gas, biomass fuel.

Application industry: Suitable for calcined limestone in metallurgy, chemical industry and building materials industry.

Lime rotary kiln product introduction

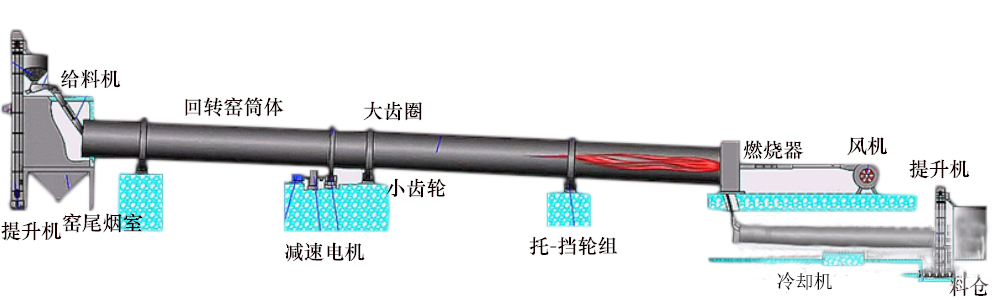

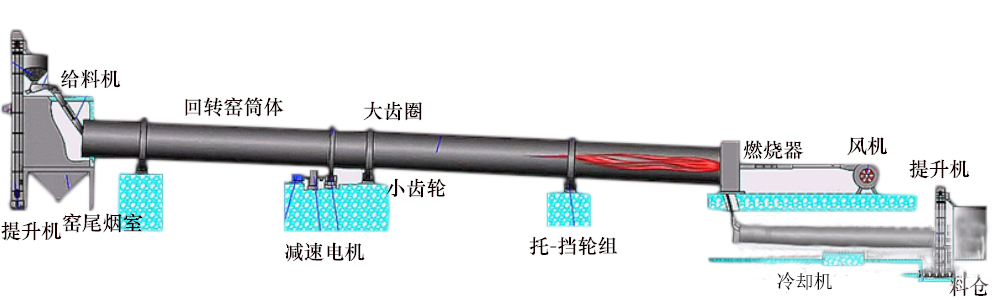

Lime rotary kiln is a new active lime special rotary kiln developed on the basis of absorbing and learning from the same type of rotary kiln at home and abroad for the calcining characteristics of limestone. This type of rotary kiln (vertical preheater and vertical cooler can be selected to compose energy-saving rotary kiln calcining system) has the characteristics of high utilization rate of raw materials, complete calcining, uniform quality, good quality, large production capacity, high operating rate, energy saving and environmental protection, easy operation and long machine life.

Outstanding advantage

1, the output of rotary kiln is stable, suitable for large, medium and small active lime production lines;

2, rotary kiln is open calcining, kiln body structure is simple, uniform heating, product quality is stable, low rate of production and overburning;

3. The vertical preheater at the end of the kiln can make full use of the high temperature flue gas produced by calcination in the rotary kiln and improve the output of the rotary kiln;

4. The vertical cooler at the kiln head can not only make the high-temperature lime quench, improve the product activity, but also facilitate transportation and storage.

Working principle

Limestone with qualified particle size is slipped into the body of the preheater through the feed chute from the top bin of the preheater. In the body of the preheater, the limestone is preheated to more than 800℃ with the high temperature flue gas from the tail of the rotary kiln, and the limestone is partially decomposed, and then pushed into the transfer chute by the hydraulic push rod, and then enters the rotary kiln for high temperature calcination. The high-temperature flue gas at the end of the rotary kiln is cooled to below 250 ° C and enters the flue gas treatment system. The high temperature calcined lime falls into the vertical cooler, and the high temperature lime is cooled by the cold air pumped into the cooling fan, and the lime is cooled to the ambient temperature below +60℃ and discharged into the vertical cooler. The secondary air cooling the lime is heated into high temperature combustion air and enters the rotary kiln to participate in combustion.

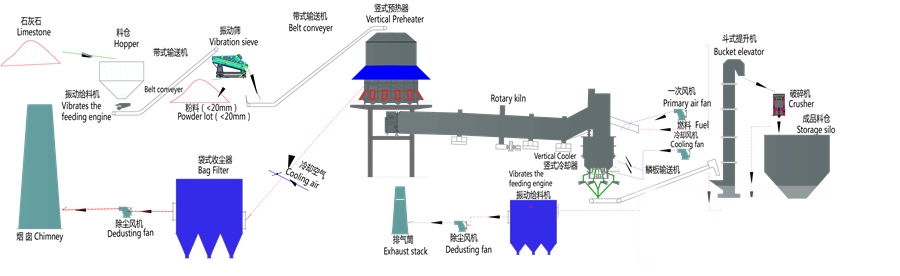

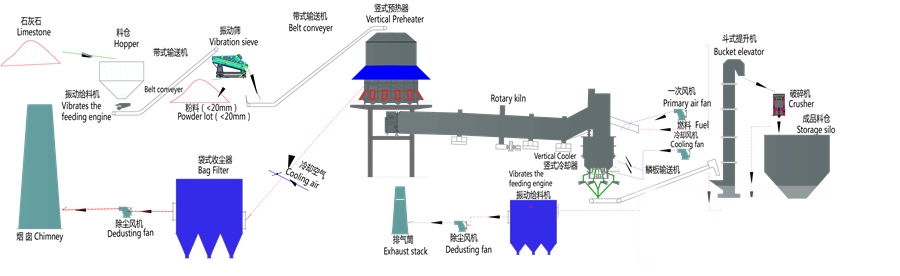

Process flow

(1) Raw material storage and transportation

The limestone with particle size of 10 ~ 50mm is transported to the factory and stacked in the material yard, and the material yard is operated by loaders. The material with qualified particle size is loaded into the receiving trough set up in the material yard by the loader, the receiving trough is fed quantitatively by the feeder, the stone is fed to the high Angle conveyor, and then sent to the screening building. After the qualified particle size of the limestone is screened, it is weighed by the high Angle conveyor and sent to the top silo of the preheater. The powder under the screen is sent to the storage yard by the 3# conveyor and is regularly transported by the forklift truck.

(2) Calcination of limestone

Limestone calcining is composed of vertical preheater + rotary kiln + vertical cooler, the output is 100~1000t/d, the material from the top of the preheater bin through the feed chute into the preheater body, at the same time, the high temperature flue gas from the rotary kiln will preheat the material to more than 1000℃, so that the limestone partial decomposition occurs, and then pushed into the tail of the rotary kiln by the hydraulic push rod. After high temperature calcination in rotary kiln, it is discharged into the cooler, cooled by the cold air blown into the fan, and cooled to the ambient temperature of +60℃ below the cooler. The air blown in by the cooler enters the rotary kiln as secondary air to participate in combustion.

(3) Finished product transportation

After the finished lime is discharged from the cooler, it is transported to each finished lime warehouse by chain conveyor, bucket elevator and belt conveyor. The discharge valve under the lime storage bin is used to load the lime in the bin into the car and the tank car before being transported out. Set up different size silos according to customer reserve requirements.

The finished product silo adopts circular silo, with 2 finished products silos of 5~50mm and 1 finished product silo of <5mm. The quantity of each silo is about 800t.

(4) Flue gas treatment

After heat exchange with limestone in the preheater, the temperature of the high temperature flue gas produced by the combustion of rotary kiln is reduced to below 250℃, and then the cyclone dust collector is carried out for the first stage of dust collection, the large particles of dust are captured, and then into the bag dust collector. After dust removal, the high temperature fan is discharged into the atmosphere, and the dust concentration of the discharged gas is less than 30mg/m3. A cold risk control system is installed at the inlet of the dust collector to protect the dust collector.

Technical parameter

| Capacity (t/d) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 800 | 1000 | 1200 |

| Main equipment | Main supporting equipment models and technical and economic indicators |

| Vertical preheater | YRQ04 | YRQ06 | YRQ06 | YRQ08 | YRQ08 | YRQ10 | YRQ12 | YRQ12 | YRQ14 | YRQ18 | YRQ20 |

| Rotary kiln | φ2.5×

40m | φ2.8×43m | φ3.0×48m | φ3.2×50m | φ3.3×52m | φ3.6×55m | φ3.8×58m | φ4.0×60m | φ4.3×65m | φ4.9×70m | φ5.1×72m |

| Vertical cooler | LSF36 | LSF44 | LSF56 | LSF80 | LSF112 |

| Calcination temperature /℃ | 1100±50 |

| Energy consumption index /(kCal/kg) | 1200±100 | ≤1150 | ≤1100 |

| Power consumption index /(kW ·h/t) | 40±5 |

| Limestone: lime | 1.7~1.78:1 |

| Lime burning rate /% | ≤5 |

|

| Lime activity /ml | ≥340(depending on the composition of the limestone) |

| Ash discharge temperature /℃ | Ambient temperature +60 |

| Limestone into kiln particle size /mm | 10~20/20~40 |

| Emission concentration /(mg/Nm3) | ≤10 |

| Number of working days per year/day | ≥340 |

| Overhaul cycle/year | 1~3 |

| Number of operators /(person/shift) | 2~3 |

| Suitable fuel | Pulverized coal, coke oven gas, charcoal furnace gas, converter gas, blast furnace gas, calcium carbide furnace gas, natural gas, diesel oil, heavy oil, liquefied petroleum gas, biomass fuel |