Rotary single drum dryer

Rotary single cylinder dryer is the material through the cylinder rotation and the lifting plate set to drive the material and high temperature flue gas for full heat exchange, so that the material drying equipment, with good drying effect, large production capacity, high operating rate, energy saving and environmental protection, easy operation and maintenance and long service life of the whole machine.

Applicable materials: clay, shale, block ore, slag, fly ash, coal and so on

Application: Rotary single cylinder dryer is widely used in bauxite, clay, shale, block ore, slag, fly ash and other drying use.

Rotary single cylinder dryer product introduction

The rotary single cylinder dryer is equipped with a variety of angles of the circular lifting plate combination device in the cylinder, which can greatly improve the heat exchange rate and shorten the drying time, and can be widely used in the drying of coal slime, bauxite, clay, slag, fly ash, shale and other materials.

Outstanding advantage

1, compact structure, smooth operation, easy operation and maintenance, good drying effect, large production capacity, high operating rate;

2, the cylinder is equipped with different forms of lifting plate according to the material situation, and the circumferential lifting plate combination device of various angles can greatly improve the heat exchange rate and shorten the drying time;

3, the support wheel support device and the support wheel support device frame overall welding is completed, vibration aging treatment, eliminate welding stress, with a large vertical lathe and boring and milling machine for integrated processing and manufacturing, to ensure the processing of each part of the precision and form tolerance, effectively improve the installation accuracy and reliability of the whole machine.

Working principle

The material enters the dryer through the feeding device. Since the cylinder is in the inclined state for slow rotation, the material moves from high end to low end in the axial direction. In the process of movement, the material is continuously lifted, scattered and moved downward in the circumference of the lifting plate, so that the material and the high-temperature flue gas can fully exchange heat until the drying reaches the specified requirements. The dried material is discharged from the discharge device.

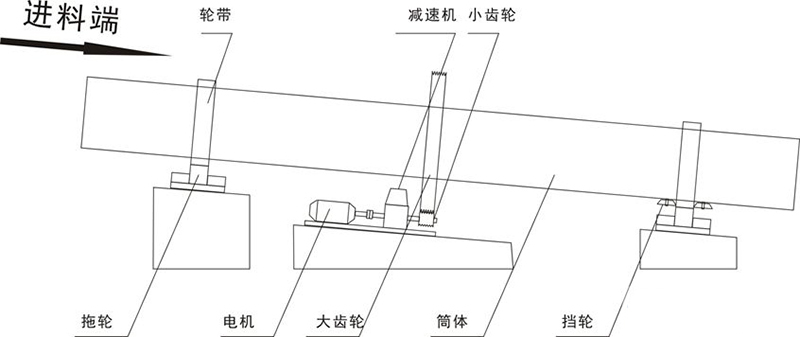

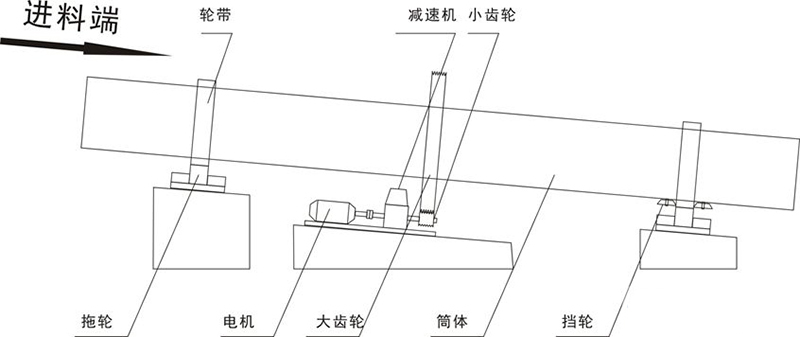

Structural composition

Rotary single drum dryer is mainly composed of transmission device, supporting device, supporting device of supporting wheel, cylinder, etc. The main structural characteristics are:

1, the single cylinder dryer has 2 to 4 fulcrum (most of the 3 fulcrum), easy to ensure that the support wheel and the cylinder pulley contact surface parallel to the axis of the cylinder;

2, the supporting device adopts rolling bearings, which greatly simplifies the supporting structure of the supporting wheel, which can reduce the loss of idle work during the operation of the dryer, and also make maintenance and overhaul more convenient;

3, there is a certain gap between the wheel belt and the cylinder, to ensure that the cylinder in the normal working state of the wheel belt tight hoop on the cylinder to strengthen the cylinder;

4, the transmission system uses a new type of AC frequency conversion speed regulation technology, compared with the traditional electromagnetic speed regulation, DC speed regulation, it is more energy saving and environmental protection, and the speed range is large, high efficiency, high precision speed regulation, smooth operation.

Technical parameter

| Specifications (m) | barrel | Production capacity (t/h) | Model | Power (kW) | Reduction gear |

| Inner diameter (mm) | Length (mm) | Dip Angle () | Speed (rpm) | Motor Model |

| φ1.2X12 | 1200 | 12000 | 1.8 | 5 | 2-5 | Y160LM-6 | 11 | ZQ500 |

| φ1.5X15 | 1500 | 15000 | 1.8 | 4.28 | 4-5 | Y160L-6 | 18.5 | ZQ650 |

| φ1.8X18 | 1800 | 18000 | 1.8 | 5 | 6-8 | Y200LI-6 | 22 | ZQ650 |

| φ2.0X20 | 2000 | 20000 | 2 | 3.38 | 7-10 | Y200L2-6 | 30 | ZQ650 |

| φ2.2X22 | 2200 | 22000 | 1.8 | 2.8 | 9-14 | Y250M-6 | 45 | ZQ650 |

| φ2.4X24 | 2400 | 24000 | 2.5 | 2.82 | 14-16 | Y280S-6 | 55 | ZQ750 |

| φ2.8X28 | 2800 | 28000 | 2.5 | 2.55 | 20-22 | Y315S-6 | 90 | ZL115 |

| φ3.0X30 | 3000 | 30000 | 2.5 | 2.69 | 22-24 | Y315LI-6 | 132 | ZL130 |

| φ3.2X32 | 3200 | 32000 | 2.5 | 2.6 | 24-26 | Y315M-4 | 200 | ZSY450 |

| φ3.6X36 | 3600 | 36000 | 2.5 | 2.51 | 30-40 | Y315L2-4 | 315 | ZL130 |

| φ4.0X40 | 4000 | 40000 | 2.5 | 2.09 | 40-45 | YKK4003-4 | 400 | ZSY630 |

| φ4.2X42 | 4200 | 42000 | 2.5 | 2.09 | 45-46 | YKK4005-4 | 400 | ZSY630 |

| φ4.5X45 | 4500 | 45000 | 2.5 | 1.92 | 46-50 | YKK4502-4 | 500 | MH3S230 |

| φ4.8X48 | 4800 | 48000 | 2.5 | 1.92 | 50-55 | YKK4504-4 | 630 | MH3S250 |

| φ5.0X 50 | 5000 | 50000 | 2.5 | 1.92 | 55-60 | YKK4505-4 | 710 | MH3S260 |