I、Basic situation

1.1 .The raw material of this project is purchased synzygous gold, the gold content of synzygous gold is 95%-96%, and the processing scale is ***kg per day.

II、Raw materials and products

2.1 Raw Materials

The raw material is purchased synzygous gold, and the gold content of synzygous gold is 95%-96%.

2.2 Products

(1) Gold ingots

The gold ingots of the project meet the national standard (GB/T4134-2015) IC-Au 99.99% requirements.

Chemical composition of gold ingot

No. | Chemical composition (mass fraction) /% |

Au≥ | Impurity content ≤ |

Ag | Cu | Fe | Pd | Bi | Sb | Pd | Mg | Sn | Cr | Ni | Mn | Total impurity sum |

IC-AU99.99 | 99.99 | 0.005 | 0.002 | 0.002 | 0.001 | 0.002 | 0.001 | 0.005 | 0.003 | - | 0.0003 | 0.0003 | 0.0003 | 0.001 |

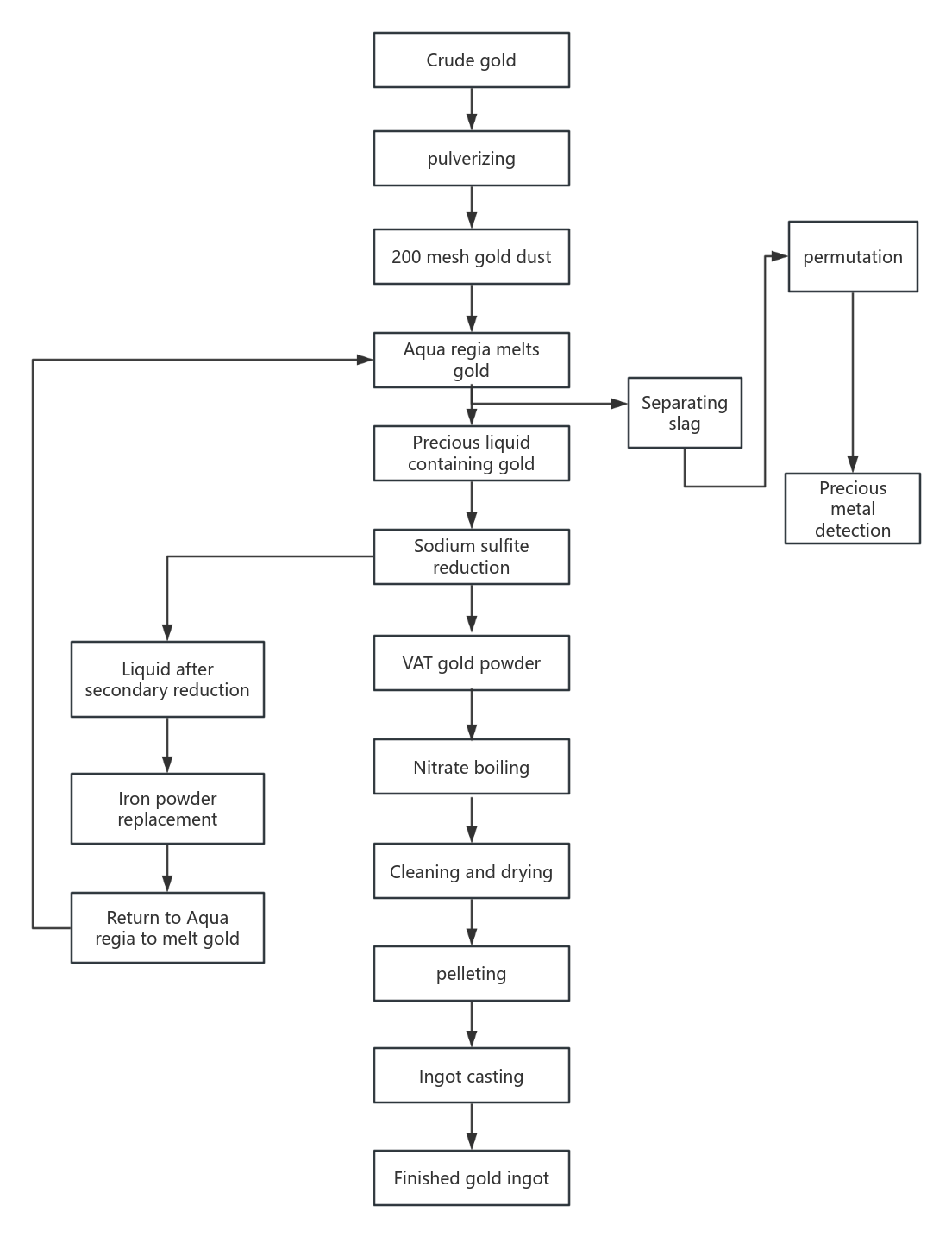

III、Process scheme

The raw material of this project is synthetic gold, due to the high purity of synthetic gold. The main process flow is - pulverizing - aqua regia dissolving - sodium sulfite reduction - acid boiling -99.99% gold - cleaning and drying - melting ingots - marking and warehousing.

3.1 Process flow chart

3.2 Gold assay refining process

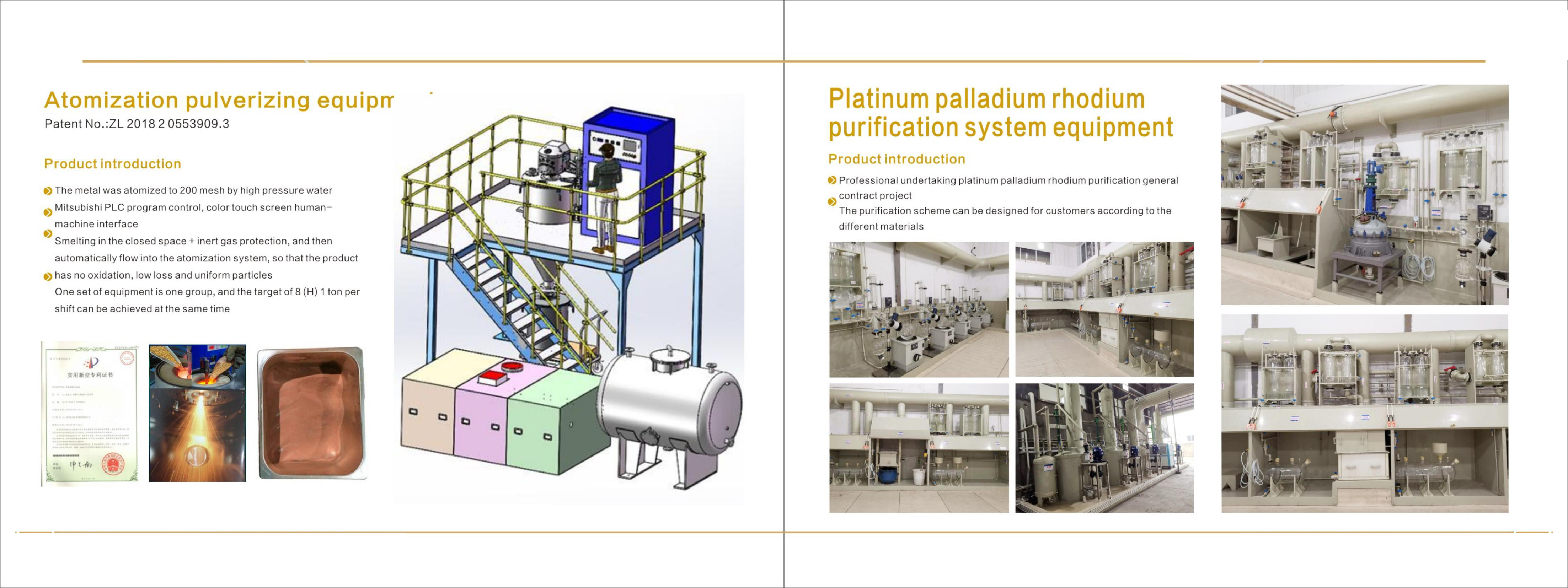

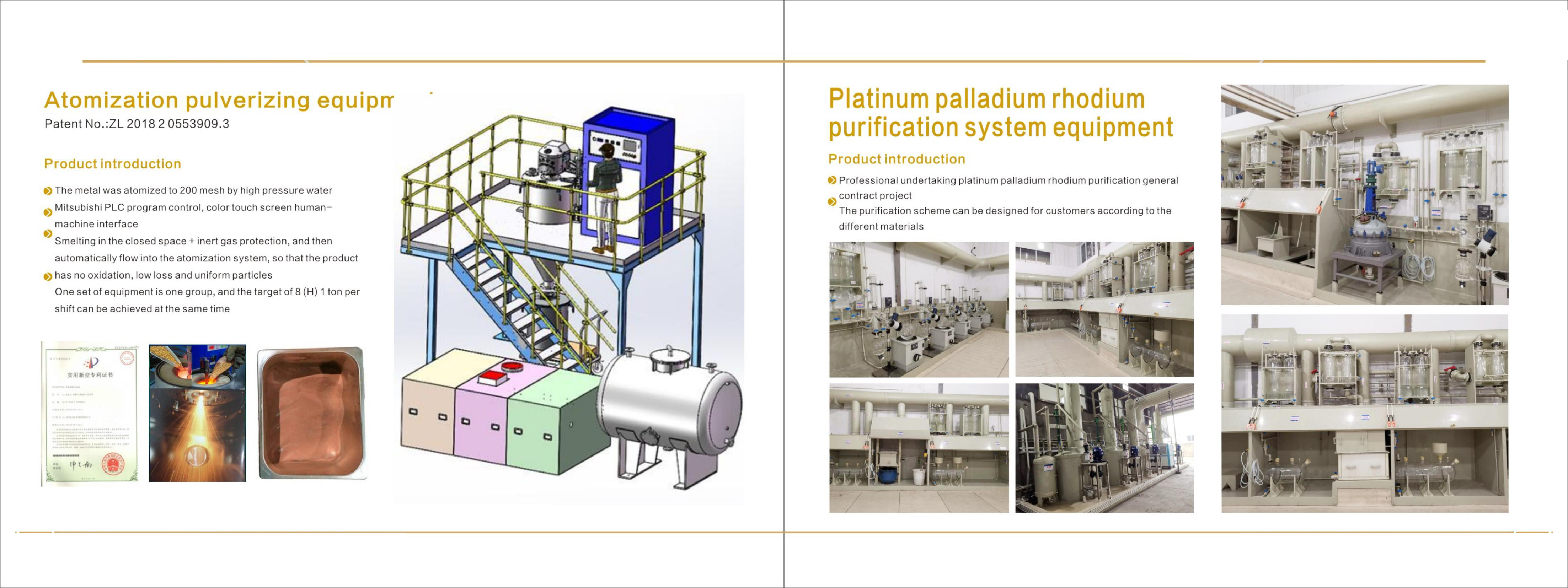

3.2.1 Milling

Since the raw material is synthetic gold, it is difficult to dissolve if it is directly put into the reaction kettle for treatment, and the silver in the raw material will form silver chloride wrapped on the surface of the raw material during the dissolution process, resulting in incomplete gold dissolution. Therefore, we designed to powder the raw material first, treat it into 200 mesh fine powder, and then enter the process of aqua Regis dissolution.

3.2.2 King's water-soluble gold

Aqua regia is added to the treated raw material, the gold reacts with the aqua regia into the solution, and filtration separates the gold from other impurities.

Au+HNO3+4HCl = HAuCl4+NO↑+2H2O

Pd+4HCl+2HNO3→H2PdCl4+2H2O+2NO2↑

Through this reaction, gold is transferred from the solid phase to the liquid phase, while impurities in the material that are insoluble in aqua regia remain in the solid phase.

3.2.3 Sodium sulfite reduction

Sodium sulfite is added into the gold-containing noble liquid to control the amount of reducing agent added, pH value, temperature and temperature rise, and control the reduction reaction speed to make gold fully reduced. This part of the gold powder contains some impurities, need to boil in nitric acid.

The reduced liquid needs to be tested to see if it contains precious metals. If it does, this part of the solution needs to be transferred to the precious metals recovery device, and iron powder is added to precipitate the precious metals. After precipitation, the liquid is transferred to the waste liquid treatment system.

Na2SO3 + 2HCl = 2NaCl + H2O + SO2↑

2HAuCl4+3SO2+6H2O = 2Au↓+ 8HCl + 3H2SO4

3.2.3 Acid cooking

The reduced gold powder contains a small amount of impurities, nitric acid can react with most metals except gold, so we use nitric acid to treat the material, impurities and nitric acid reaction into the solution, and gold is not dissolved, filtration will separate its impurities from gold. The impurity removal solution was replaced by tailing solution.

3.2.4 Drying

After cleaning the acid cooking powder, put it into the titanium tray, put it into the high temperature furnace, dry it at 200 degrees, and weigh it for use

3.2.5 pelleting

After drying the qualified sponge gold, put the sponge gold into the pelletizer to turn on the cooling circulating water to turn on the power supply of the pelletizer to wait for the metal to completely melt, and sample with a glass vacuum tube (you can also take gold particles as samples after pelletizing).

Small metal balls of 2~5mm are melted by pelletizing machine, and then loaded into a high temperature furnace at 400 degrees to dry again, which is conducive to counterweight and vacuum melting.

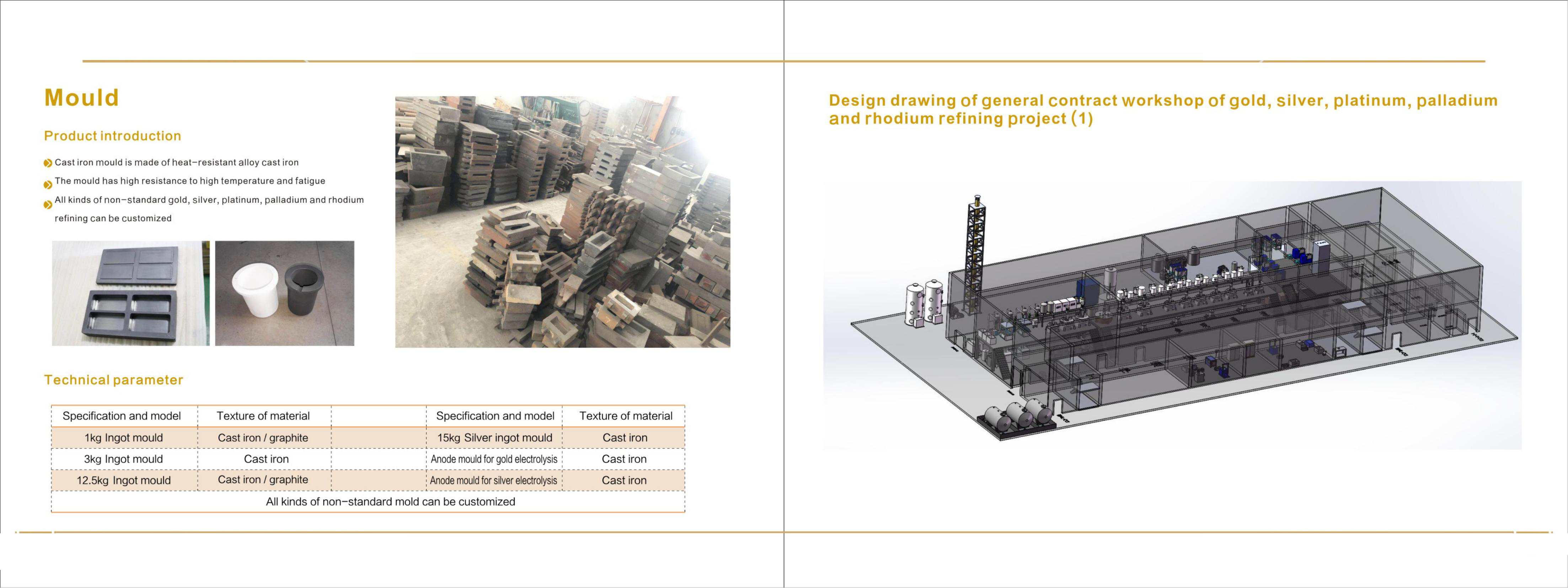

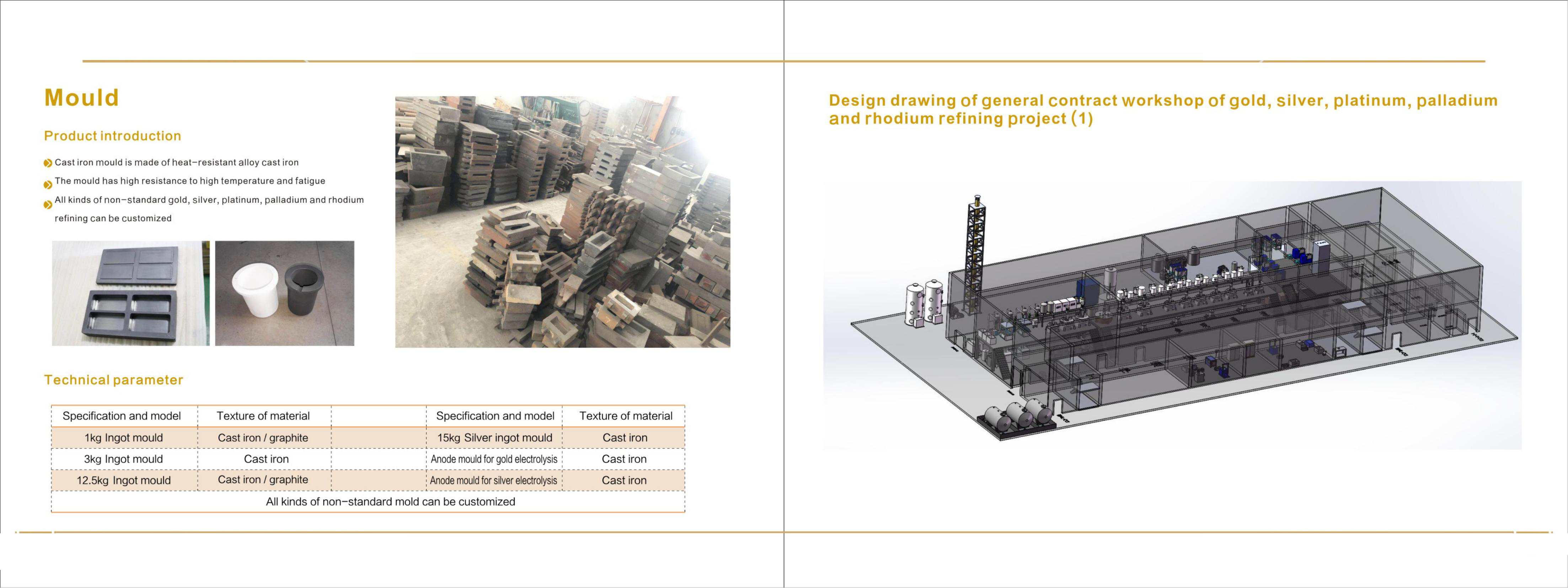

3.2.6 Gold grain counterweight

According to the weight requirements of 50g-1kg gold ingots, the dried gold grains are weighed to the required weight, put into a small stainless steel bowl for reserve, and then the gold grains are poured into a high-purity graphite mold.

3.2.7 Vacuum ingot

The gold grains with good weight are added to the high purity graphite mold and put into the vacuum automatic ingot casting machine. After setting the temperature and time, the mirror gold ingots with gold grains can be cast automatically.

3.2.8 Marking

Use pneumatic marking machine (laser marking or hydraulic marking) to print trademarks.

Gold ingot after marking

3.3 Waste gas treatment technology

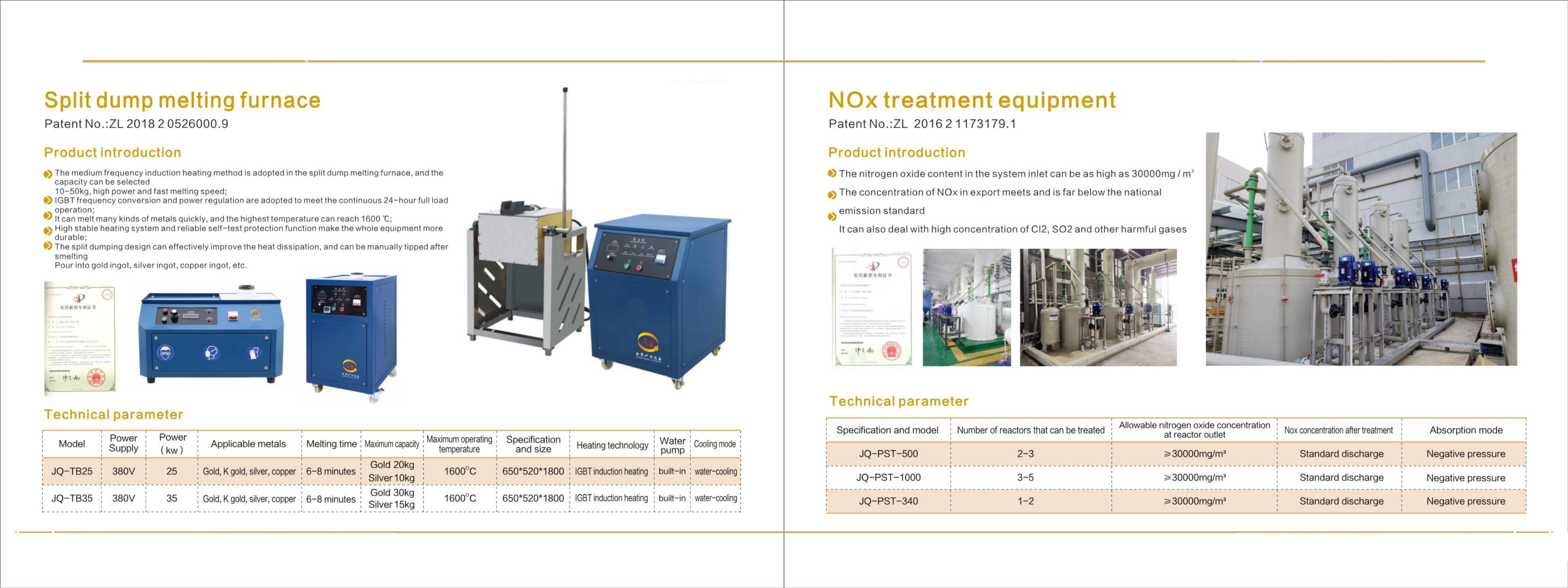

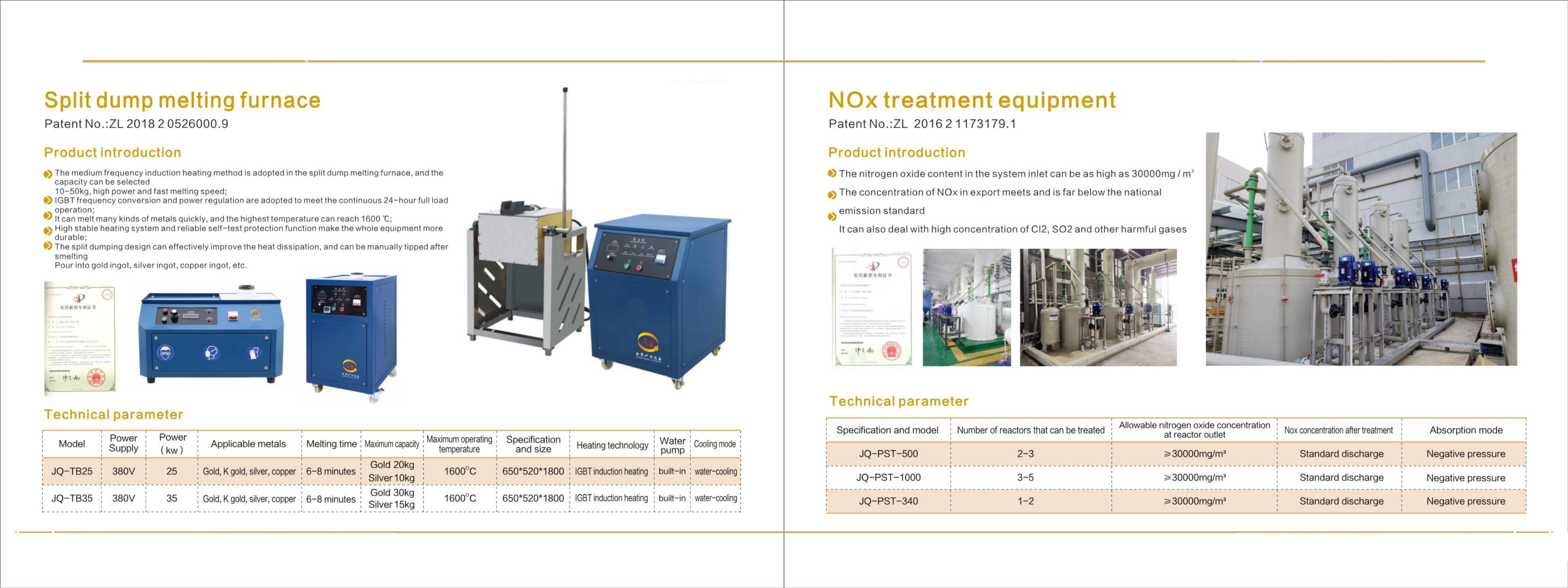

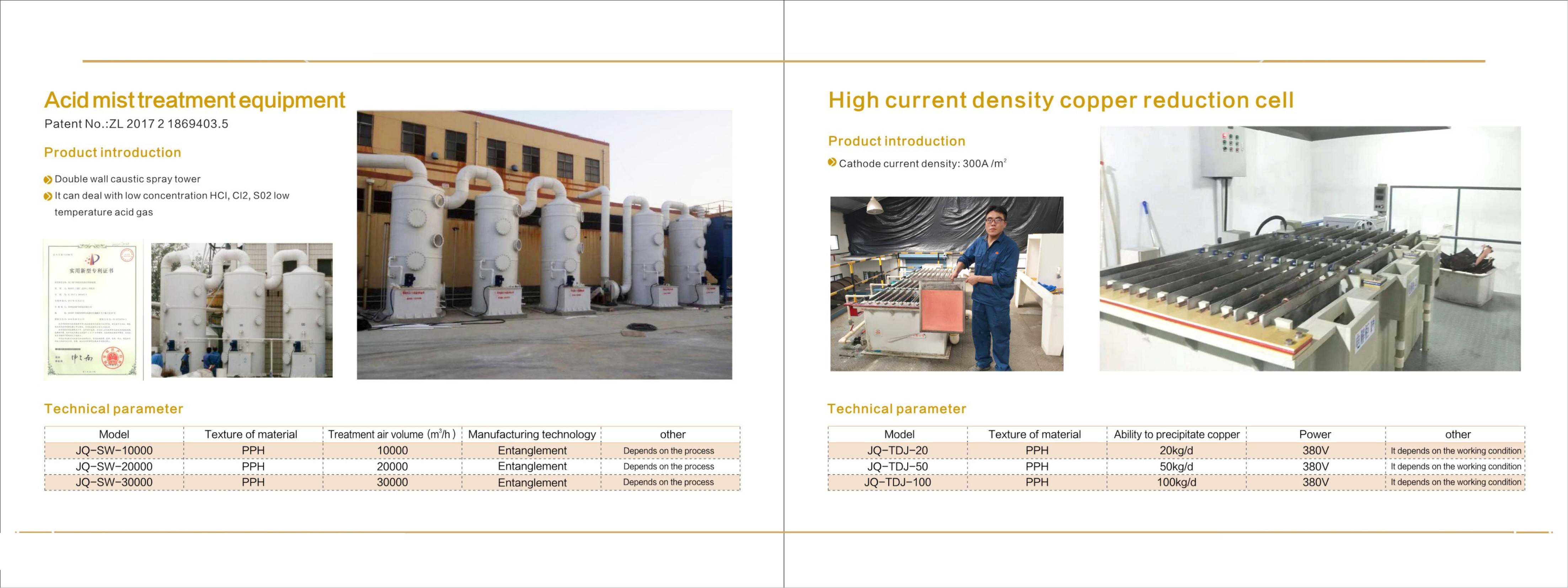

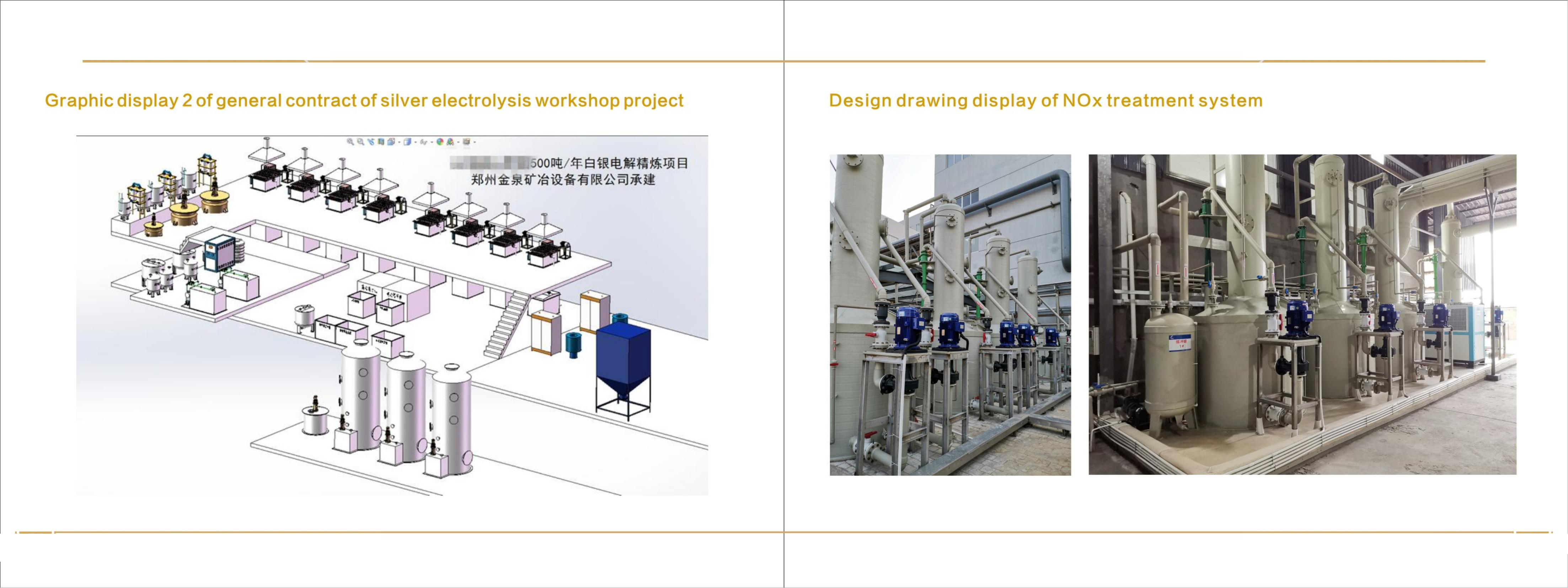

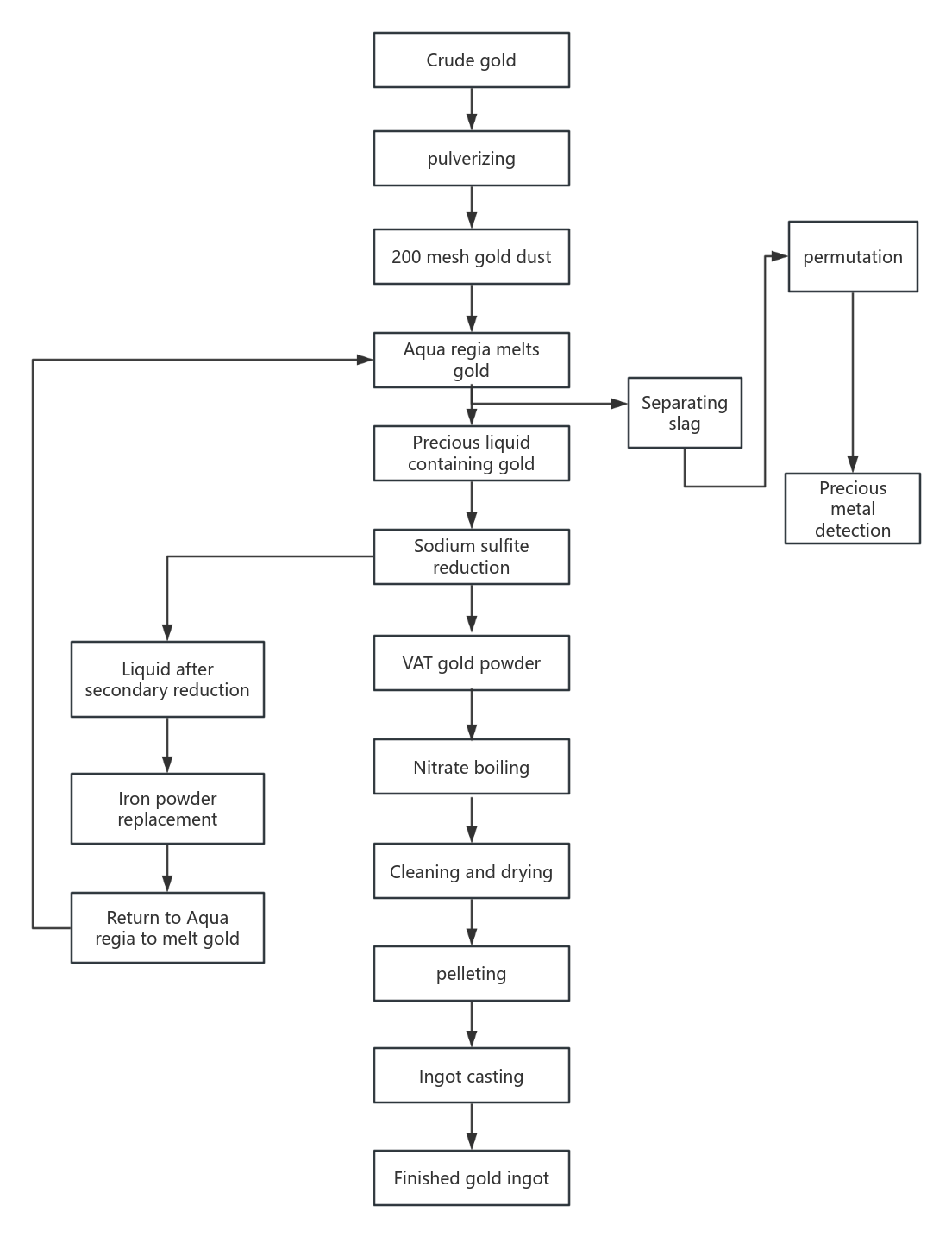

Waste gas absorption mainly adopts the separate treatment process of high-low concentration waste gas, and according to the exhaust gas emission characteristics of different working conditions, targeted equipment is configured for treatment to ensure that the exhaust gas is discharged to the standard.

High-concentration nitrogen oxide waste gas is mainly produced by the process of soluble gold regia and nitric acid cooking, which is mainly nitrogen dioxide and nitric oxide waste gas, and also contains a small amount of HCl gas. The exhaust gas at the outlet of the reactor will contain some acid and noble liquid, so it is necessary to install a high-efficiency condensation reflux device at the outlet of the reactor.

There is condensate water about 8℃ in the gas fog separator, and the noble liquid contained in the flue gas is cooled and liquefied back to the reaction kettle when passing through the gas fog separator.

The high-concentration nitrogen oxide waste gas produced by the removal of impurities by nitric acid is first removed by a bubble absorption tank, and then enters a bubble absorption tank to oxidize NO in the nitrogen oxide waste gas to NO2, and then enters a three-stage jet jet jet tower for treatment. The agent of the jet jet jet tower is a single lye, and the product of absorbing nitrogen oxide is sodium salt.

Specific process: High-concentration waste gas - condensation reflux - oxidation absorption - acid removal - nitrogen oxide removal - into the low-concentration nitrogen oxide treatment system.

Low-concentration nitrogen oxide exhaust gas is mainly unorganized exhaust gas in the workshop, mainly reduction kettle, filter pan, acid storage tank, etc., which is directly processed by two-stage spray tower after aggregation. The spray tower produced by our company adopts small diameter, multi-layer spray structure, special spray device, forming multi-layer gas film, and high wind pressure extraction equipment to ensure that the exhaust gas can contact and react with the agent as much as possible. Its absorption effect is better.

Specific process: low concentration exhaust gas - two-stage spray absorption - standard emission.

3.4 Wastewater treatment process description

After the waste liquid generated by each process is collected, it goes into the neutralization tank first, and the precious metal content is tested. For the waste liquid with high precious metal content, it is returned to the front end to recover the precious metal. For the reduced liquid after standing, the precious metal containing slag is first replaced, and then filtered, neutralized and precipitated, plate and frame press filtration, and activated carbon adsorption.

3.4.1 Neutralization and precipitation

The waste liquid enters the neutralization mixing tank, and NaOH and sodium carbonate are added to the neutralization mixing tank to adjust the pH to 7. The heavy metals in the wastewater form hydroxide precipitation and carbonate precipitation through neutralization and precipitation reaction. Reaction principle:

H+ + OH- = H2O

Me2+ + 2NaOH = Me(OH)2+ 2Na+ (Me representative Cu、Zn etc)

Me2+ + Na2CO3 = MeCO3 + 2Na+ (Me representative Cu、Zn etc)

2Ag+ + 2NaOH = Ag2O+H2O

2Ag+ + Na2CO3 = Ag2CO3 + 2Na+

3.4.2 Plate and frame press filter

The neutralized solution (including sediment) enters the plate and frame filter press for filtration, the filtrate enters the activated carbon adsorption column for adsorption treatment, and the filter cake is entrusted with qualified units for processing.

3.4.3 Activated Carbon adsorption

The filtrate filtered by the plate and frame filter press enters the three-stage activated carbon adsorption column for adsorption treatment. Activated carbon is a porous material with a large specific surface area, which can reach more than 1000m2/g. The activated carbon adsorption method has high treatment degree for metal ions in water and good adsorption effect.

The product catalog is as follows: