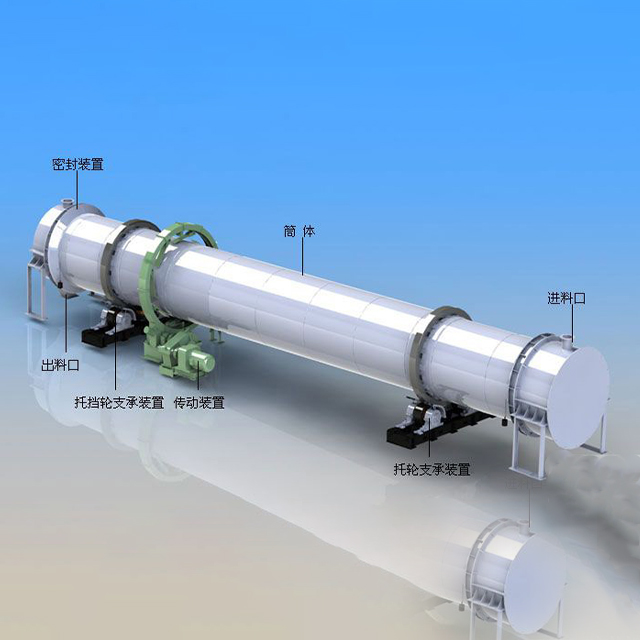

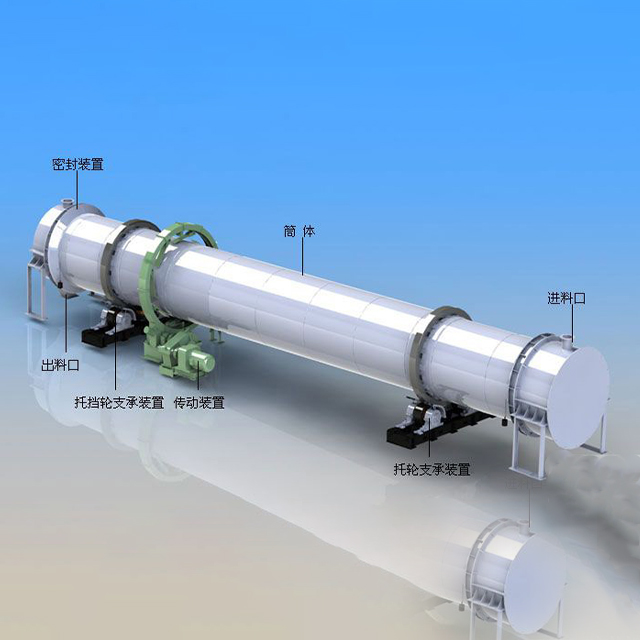

Single cylinder cooling machine

Product introduction: The company's single barrel cooling machine diameter specifications model for Ø1.0×15m-Ø3.0×30m, 20 models, inclination 3.5-5%, speed 1-5r/min, supporting motor power 7.5KW-75KW, can meet a variety of material cooling needs.

Volume: 11.8-212m³

Model specification: Ø1.0×15m-Ø3.0×30m

Application: electric power, chemical industry, metallurgy, building materials, light industry, mining

Single cylinder cooling machine product introduction

Single barrel cooling machine is through the rotation of the cylinder to drive the high temperature material and cold air for full heat exchange, so that the material cooling equipment, with good cooling effect, large capacity, high operating rate, energy saving and environmental protection, easy operation and maintenance and long machine life, can be widely used in cement, lime, ceramic, metal magnesium and other industries.

Outstanding advantage

1. The whole frame of the supporting device and supporting device of the supporting wheel is welded, the vibration aging treatment is carried out, and the welding stress is eliminated. The integrated processing and manufacturing of the large vertical lathe and boring and milling machine are used to ensure the processing, matching accuracy and shape and position tolerance of each part, and the installation accuracy and reliability of the whole machine are effectively improved.

2, good cooling effect, large capacity, high operating rate;

3, a variety of angles of the circular lifting plate combination device, can greatly improve its heat exchange rate, shorten the cooling time;

4, compact structure, smooth operation, easy operation and maintenance.

Working principle

The material enters the cooling machine through the feeding device. The cooling machine rotates, and its internal lifting plate drives the material to fully exchange heat with the air. At the same time, with the cylinder rotating continuously according to the design inclination and speed, the material also rolls forward periodically in the cylinder body, so as to transport the material from the feed end to the discharge end, and ensure that the material is cooled to below 200 ° C during the time of passing the monobar cooling machine, so as to complete the entire cooling process.

Technical parameter

| Specifications (m) | Barrel | Motor | Reduction type number | Overall dimensions (L* W * H) | Weight (t) |

| Volume (m³) | Speed (rpm) | Slope (%) | Model number | Power (kW) | (mm) |

| φ1x15 | 11.8 | 5 | 5 | YCT200-4B | 7.5 | ZQ400 | 15000x1876x2069 | 9.5 |

| φ 1.2x12 | 13.57 | 5 | 5 | YCT225-4A | 11 | ZQ500 | 12000x2159x2475 | 10.3 |

| φ1.2x15 | 17 | 4-5 | 5 | YCT225-4B | 15 | ZQ500 | 15000x2294x2475 | 12.8 |

| Φ 1.2x20 | 22.6 | 4-5 | 5 | YCT225-4B | 15 | ZQ500 | 20000x2294x2475 | 16.8 |

| φ1.5x10 | 17.67 | 3-5 | 5 | YCT225-4B | 15 | ZQ650 | 10000x2655x2895 | 16.5 |

| φ1.5x14 | 24.9 | 3-5 | 5 | YCT225-4B | 15 | ZQ650 | 14000x2655x2895 | 19.2 |

| φ1.5x18 | 31.8 | 3-5 | 5 | YCT250-4A | 18.5 | ZQ650 | 18000x2655x2895 | 22.9 |

| φ1.5x20 | 35.3 | 3-5 | 5 | YCT250-4A | 18.5 | ZQ650 | 20000x2655x2895 | 25.4 |

| Φ 1.8x16 | 30.5 | 3-5 | 4 | YCT250-4B | 22 | ZQ750 | 16000x3060x2980 | 35.4 |

| φ1.8x18 | 45.8 | 3-5 | 4 | YCT250-4B | 22 | ZQ750 | 18000x3060x2980 | 32.3 |

| φ1.8x20 | 50.9 | 3-5 | 4 | YCT250-4B | 22 | ZQ750 | 20000x3060x2980 | 39.2 |

| φ2.0x16 | 50.3 | 3-5 | 3.5 | YCT250-4B | 22 | ZQ750 | 16000x3340x3420 | 38.6 |

| Φ2.0x20 | 62.8 | 3-5 | 3.5 | YCT280-4A | 30 | ZQ750 | 20000x3340x3420 | 42.8 |

| Φ2.2x14 | 53.2 | 3-5 | 3.5 | YCT280-4A | 30 | ZQ750 | 14000x3620x3570 | 45.3 |

| φ2.2x18 | 68.4 | 3-5 | 3.5 | YCT280-4A | 30 | ZQ750 | 18000x3620x3570 | 49.4 |

| φ2.2x20 | 76 | 3-5 | 3.5 | YCT280-4A | 30 | ZQ750 | 20000x3620x3570 | 51.8 |

| φ2.4x16 | 72.3 | 3-4 | 3.5 | YCT280-4A | 30 | ZQ850 | 16000x3860x3760 | 58.8 |

| φ2.4x20 | 90.4 | 3-4 | 3.5 | YCT280-4A | 30 | ZQ850 | 20000x3860x3760 | 63.9 |

| φ2.8x28 | 172 | 2.5 | 3.5 | Y280M-6 | 55 | ZQ1000 | 28000x4350x4200 | 130 |

| φ3x30 | 212 | 1-2 | 3.5 | Y315S-6 | 75 | ZL115 | 30000x4860x4630 | 169 |