Slag dryer

The slag dryer has reasonable design, excellent production, stable performance, advanced technology, high output, low energy consumption, small footprint and high degree of mechanization.

Equipment model: Ø1.2×12m-Ø5.0×50m

Drying capacity: 2~60(t/h)

Application: Slag dryer equipment is widely used in building materials, metallurgy, mineral processing, chemical industry, cement and other industries, it is suitable for a variety of combustion furnace use: high temperature boiling furnace, coal grinding powder injection furnace and artificial coal furnace, can be used for drying slag, calcium carbide slag, limestone, clay, river sand, quartz sand, water slag and other materials.

Slag dryer product introduction

Slag dryer is a rotary dryer, which is mainly composed of rotary cylinder, air extraction equipment, high-speed dispersion equipment, lifting plate, self-cleaning device, transmission device, conveying equipment, hot air equipment, reducer, support device and sealing device. The slag dryer has reasonable design, excellent production, stable performance, advanced technology, high output, low energy consumption, small footprint and high degree of mechanization.

Working principle

When the slag dryer is working, as the rotating material of the cylinder is run to the lower end by the action of gravity, the wet material is directly or indirectly given to the heat carrier during the forward movement of the wet material in the cylinder body, so that the wet material can be dried, and then the heat carrier is sent out by the belt machine or screw conveyor at the discharge end. Generally, the cyclone dust collector is required to capture the material in the gas, and the heat carrier is generally divided into hot air, flue gas, etc., if it is necessary to further reduce the dust content of the tail gas, it should also be discharged after the bag dust collector or wet dust collector.

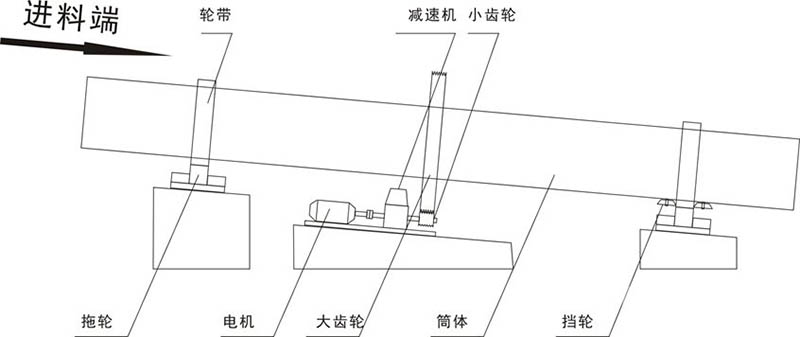

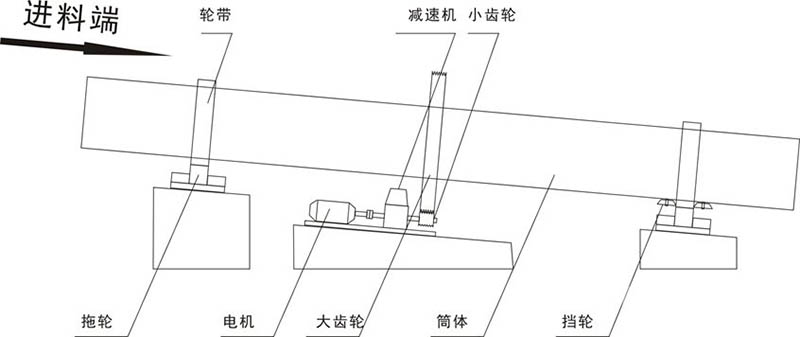

Structural composition

The slag dryer is mainly composed of a transmission device, a support device, a support device for a support wheel, a cylinder, etc. The main structural characteristics are:

1, the single cylinder dryer has 2 to 4 fulcrum (most of the 3 fulcrum), easy to ensure that the support wheel and the cylinder pulley contact surface parallel to the axis of the cylinder;

2, the supporting device adopts rolling bearings, which greatly simplifies the supporting structure of the supporting wheel, which can reduce the loss of idle work during the operation of the dryer, and also make maintenance and overhaul more convenient;

3, there is a fixed gap between the wheel belt and the cylinder to ensure that the cylinder in the normal working state of the wheel belt tight hoop on the cylinder to strengthen the cylinder;

4, the transmission system uses a new type of AC frequency conversion speed regulation technology, compared with the traditional electromagnetic speed regulation, DC speed regulation, it is more energy saving and environmental protection, and the speed range is large, high efficiency, high precision speed regulation, smooth operation.

Technical parameter

| Specifications (m) | barrel | Production capacity (t/h) | Power (kW) |

| Inner diameter (mm) | Length (mm) | Dip Angle () | Speed (rpm) |

| φ1.2X12 | 1200 | 12000 | 1.8 | 5 | 2-5 | 11 |

| φ1.5X15 | 1500 | 15000 | 1.8 | 4.28 | 4-5 | 18.5 |

| φ1.8X18 | 1800 | 18000 | 1.8 | 5 | 6-8 | 22 |

| φ2.0X20 | 2000 | 20000 | 2 | 3.38 | 7-10 | 30 |

| φ2.2X22 | 2200 | 22000 | 1.8 | 2.8 | 9-14 | 45 |

| φ2.4X24 | 2400 | 24000 | 2.5 | 2.82 | 14-16 | 55 |

| φ2.8X28 | 2800 | 28000 | 2.5 | 2.55 | 20-22 | 90 |

| φ3.0X30 | 3000 | 30000 | 2.5 | 2.69 | 22-24 | 132 |

| φ3.2X32 | 3200 | 32000 | 2.5 | 2.6 | 24-26 | 200 |

| φ3.6X36 | 3600 | 36000 | 2.5 | 2.51 | 30-40 | 315 |

| φ4.0X40 | 4000 | 40000 | 2.5 | 2.09 | 40-45 | 400 |

| φ4.2X42 | 4200 | 42000 | 2.5 | 2.09 | 45-46 | 400 |

| φ4.5X45 | 4500 | 45000 | 2.5 | 1.92 | 46-50 | 500 |

| φ4.8X48 | 4800 | 48000 | 2.5 | 1.92 | 50-55 | 630 |

| φ5.0X 50 | 5000 | 50000 | 2.5 | 1.92 | 55-60 | 710 |