Slime dryer

Our slime dryer specification range is Ø1.2×12m-Ø5.0×50m, supporting the main motor power 11-710kW, can dry 2-60 tons of materials per hour.

Output: 2-60t/h

Model: Ø1.2×12m-Ø5.0×50m

Application: drying of viscous filter cake materials such as coal slime, water washed coal, urban sludge, coal slime, choline chloride, red mud, biological waste residue, etc.

Slime dryer product introduction

The slime dryer is a new type of special slime drying equipment developed by our company on the basis of the existing dryer. The slime dryer has a depolymerization mechanism, movable grate type wing plate, cleaning device and crushing impact and dispersion device, which can dry the viscous materials that the ordinary rotary dryer cannot handle. It is a product developed and designed for the viscous filter cake materials.

Outstanding advantage

1, slime dryer processing capacity is large, suitable for single production capacity of 2 ~ 60t/h scale production;

2. The operation cost of the slime dryer is low, and the volume heat transfer coefficient is as high as 300-450kcal/m3·℃·h;

3. The speed of the cylinder can be adjusted stepless. By adjusting the speed of the cylinder and the air inlet temperature of the dryer, it can adapt to the properties of different forms of incoming materials and meet the water requirements of different products;

4, equipment reliable operation, strong anti-overload ability. The use of aligning type support wheel structure, reduce wear and power consumption. The use of special stop wheel structure reduces the horizontal thrust caused by equipment tilt work.

Working principle

1. The slime is sent to the hopper by the belt conveyor or bucket elevator, and then the feeder of the hopper enters the feeding end through the feeding pipe, and the inclination of the feeding pipe is greater than the natural inclination of the material, so that the material smoothly flows into the slime dryer.

2. Slime dryer cylinder is a rotating cylinder slightly inclined to the horizontal line, the material is added from the higher end, the heat carrier enters from the low end, and the material is in countercurrent contact, there are also heat carrier and material together and flow into the cylinder, with the rotation of the cylinder material by gravity to run to the bottom end, wet material in the barrel moving forward process, The heat transfer of the heat carrier is obtained directly or indirectly, so that the wet material can be dried, and then sent out by the belt machine or screw conveyor at the discharge end.

3, the wall of the coal mud dryer cylinder is equipped with a copy plate, its role is to copy the material and spread it, so that the contact surface of the material and the air flow increases, to improve the drying rate and promote the material forward, the heat carrier is generally divided into hot air, flue gas, etc., the heat carrier after the dryer.

4, generally need the cyclone dust collector to collect the material in the gas, if it is necessary to further reduce the dust content of the tail gas, it should also be discharged after the bag type dust collector or wet dust collector.

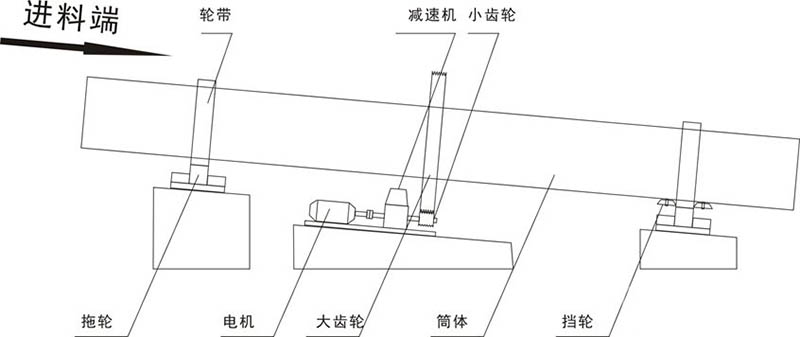

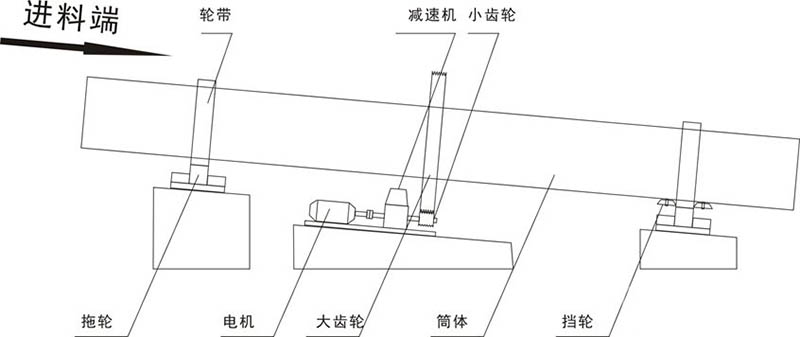

Structural composition

The slime dryer is mainly composed of a transmission device, a support device, a support device for a support wheel, a cylinder, etc. The main structural characteristics are:

1, the single cylinder dryer has 2 to 4 fulcrum (most of the 3 fulcrum), easy to ensure that the support wheel and the cylinder pulley contact surface parallel to the axis of the cylinder;

2, the supporting device adopts rolling bearings, which greatly simplifies the supporting structure of the supporting wheel, which can reduce the loss of idle work during the operation of the dryer, and also make maintenance and overhaul more convenient;

3, there is a certain gap between the wheel belt and the cylinder, to ensure that the cylinder in the normal working state of the wheel belt tight hoop on the cylinder to strengthen the cylinder;

4, the transmission system uses a new type of AC frequency conversion speed regulation technology, compared with the traditional electromagnetic speed regulation, DC speed regulation, it is more energy saving and environmental protection, and the speed range is large, high efficiency, high precision speed regulation, smooth operation.

Technical parameter

| Specifications (m) | barrel | Production capacity (t/h) | Power (kW) |

| Inner diameter (mm) | Length (mm) | Inclination (°) | Speed (rpm) |

| φ1.2X12 | 1200 | 12000 | 1.8 | 5 | 2-5 | 11 |

| φ1.5X15 | 1500 | 15000 | 1.8 | 4.28 | 4-5 | 18.5 |

| φ1.8X18 | 1800 | 18000 | 1.8 | 5 | 6-8 | 22 |

| φ2.0X20 | 2000 | 20000 | 2 | 3.38 | 7-10 | 30 |

| φ2.2X22 | 2200 | 22000 | 1.8 | 2.8 | 9-14 | 45 |

| φ2.4X24 | 2400 | 24000 | 2.5 | 2.82 | 14-16 | 55 |

| φ2.8X28 | 2800 | 28000 | 2.5 | 2.55 | 20-22 | 90 |

| φ3.0X30 | 3000 | 30000 | 2.5 | 2.69 | 22-24 | 132 |

| φ3.2X32 | 3200 | 32000 | 2.5 | 2.6 | 24-26 | 200 |

| φ3.6X36 | 3600 | 36000 | 2.5 | 2.51 | 30-40 | 315 |

| φ4.0X40 | 4000 | 40000 | 2.5 | 2.09 | 40-45 | 400 |

| φ4.2X42 | 4200 | 42000 | 2.5 | 2.09 | 45-46 | 400 |

| φ4.5X45 | 4500 | 45000 | 2.5 | 1.92 | 46-50 | 500 |

| φ4.8X48 | 4800 | 48000 | 2.5 | 1.92 | 50-55 | 630 |

| φ5.0X 50 | 5000 | 50000 | 2.5 | 1.92 | 55-60 | 710 |