Candy and biscuit equipment Product introduction

Gummy candy production line equipment is divided into gel gummy candy production lines and starch mold gel gummy candy production lines

Large-scale gummy candy production line

ZY-800 large-scale gummy candy production line

ZY-600 large-scale gummy candy production line

ZY-450 large-scale gummy candy production line

Medium-sized gummy candy production line

ZY-300 large-scale gummy candy production line

ZY-150 large-scale gummy candy production line

ZY-80 large-scale gummy candy production line

Small gummy machine

ZY-ASC fully automatic small gummy machine

ZY-SSC semi-automatic small candy machine

Starch mold colloid gummy candy casting production line

Three-head starch mold gummy candy production line

Semi-automatic starch mold gummy production line

Gel gummy candy production line (gel gummy candy pouring production line

The raw materials for making gummy candies can be gelatin, pectin, carrageenan, AGAR, etc. The gel gummy candy casting line is manufactured in accordance with GMP standards, with stable product quality and meeting the hygiene requirements of food GMP. By changing different configurations, various types of gummy candies can be produced, such as single-color gummy candies, two-color gummy candies, striped gummy candies, and so on.

Large-scale gummy candy production line

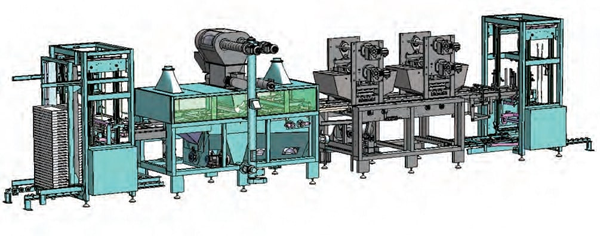

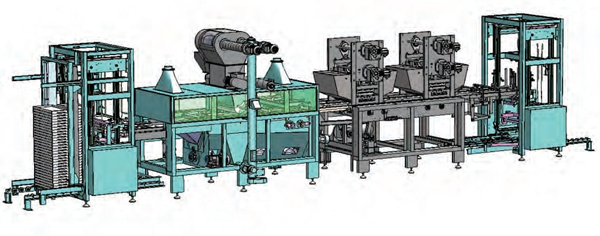

The fully automatic PLC-controlled gel soft candy production line equipment can meet the demands for various shapes and colors of gel soft candies. It is a continuous production equipment for colloidal candies. It can produce single-color and double-color sugar. Gel gummies of various shapes and colors can also be produced by changing molds or pouring heads. Complete the quantitative injection and mixing of flavor, pigment and acid solutions online. Automated production can not only produce products of stable quality, but also save labor and occupy space, thereby reducing production costs.

The production process of the soft candy production line

Interlayer pot - Mixing tank - rotor pump - storage tank - Casting molding machine (with cold cabinet) - Cooling tunnel - Discharge conveyor - Oil injector - packaging machine

Main equipment for gel gummy candies

Double-layered pot

The double-layer pot is mainly used for dissolving and boiling raw materials (glucose, granulated sugar, water). Electric heating is adopted, featuring a large heating area, uniform heating and easy control of heating temperature, which can improve product quality and shorten processing time.

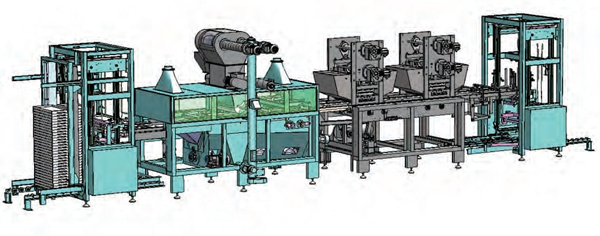

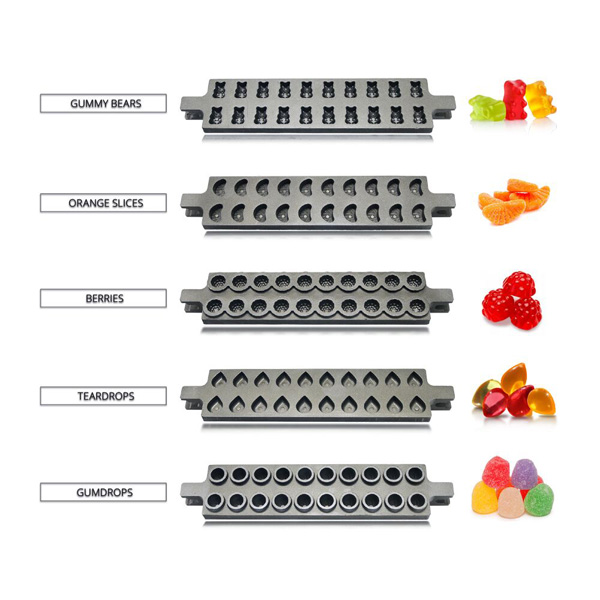

2. Gummy mold

Customers can put forward their own design concepts, and we will complete the mold drawings. During the operation of the machine, just by changing different molds, candies of different shapes can be produced.

3. Pouring machine and cooling tunnel

This machine is controlled by a PLC system, and parameters such as temperature and pouring speed can all be controlled on the touch screen. Meanwhile, variable frequency speed regulation is adopted to control the accurate flow rate of the sugar liquid, ensuring the stability of the sugar paste quality.

4. Fuel injector (optional)

This machine can coat a layer of oil on the surface of gummy candies before or after they are dried, making the surface of the candies brighter. Meet the customers' demands for producing different styles of candies.

5. Sugar Coating Machine (optional)

This machine can coat frosting on the surface of gummy candies before or after they are dried. Meet the customers' demands for producing different styles of candies

6. Soft candy self-stacking tray and trolley (optional)

After the gummy candies are formed, place them in a self-stacking tray and stack them layer by layer. Then, use a trolley to push the self-stacking tray filled with candies into the drying room for drying

ZY-800 large-scale gummy candy production line

Model :ZY800Q

Output :800kg/h

Although: According to the size of the grid

Hysteresis velocity :25-55n/min

Working environment requirements: Nirvana 20-25 ° C; Humidity: 55%, 20-25 ° C

Overall power :39kw/380v

The overall length of the machine is 25 meters

Total weight of the whole machine: 8,200 kg

Equipment process flow:

Dissolving sugar → Filtering → Boiling sugar → cooling → adding additives → Casting into shape → cooling → demolding → drying room → packaging → boxing

Characteristics

The mixing system adopts a quantitative pump and a dynamic mixer, and the color of the syrup after mixing is uniform. The amounts of pigments and fragrances can be adjusted at will.

After years of technological upgrading and improvement, the pouring head has achieved stable, accurate and reliable quantitative pouring

The replacement and operation of the punch rod are simple and convenient, and the weight of the sugar grains can be adjusted online.

The temperature of the electric heating for heat preservation can be set arbitrarily

The refrigeration units of the entire cooling tunnel are assembled in cold storage cabinets for precise temperature control

The chain structure is equipped with rotating brushes to ensure candy demolding

Non-standard machines can be customized according to the site requirements of customers

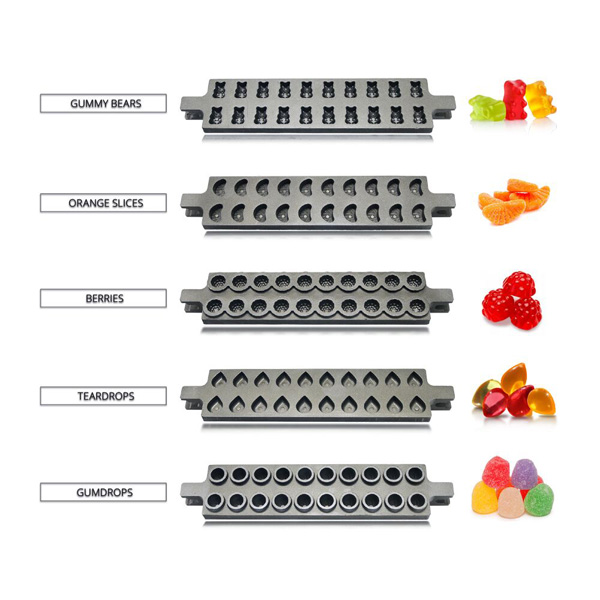

ZY-600 large-scale gummy candy production line

Model :ZY600Q

Output :600kg/h

Although: According to the size of the grid

Hysteresis velocity :25-55n/min

Working environment requirements: Nirvana 20-25 ° C; Humidity: 55%, 20-25 ° C

Overall power :36kw/380v

The overall length of the machine is 22 meters

Total weight of the whole machine :6000kg

Equipment process flow:

Dissolving sugar → Filtering → Boiling sugar → cooling → adding additives → Casting into shape → cooling → demolding → drying room → packaging → boxing

With years of experience in candy machinery production, we offer a comprehensive service covering product design and development, production and sales, installation, technical training, and after-sales support

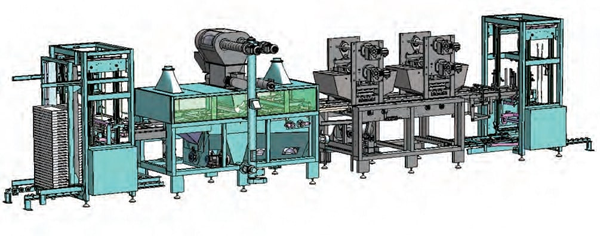

ZY-450 large-scale gummy candy production line

Model :ZY450Q

Output :450kg/h

Although: According to the size of the grid

Hysteresis velocity :25-55n/min

Working environment requirements: Nirvana 20-25 ° C; Humidity: 55%, 20-25 ° C

Overall power :32kw/380v

The overall length of the machine is 20m

Total weight of the whole machine :5000kg

Equipment process flow:

Dissolving sugar → Filtering → Boiling sugar → cooling → adding additives → Casting into shape → cooling → demolding → drying room → packaging → boxing

The advantages of the gummy candy production line

The technology features rapid pouring, rapid cooling, high production speed and high precision, convenient replacement of spare parts, and a complete after-sales system

Medium-sized gummy candy production line

This gummy candy production line can produce gummy candies of various shapes and colors according to molds. It is a continuous production equipment for colloidal candies.

It can produce single-color and double-color sugar. Gel gummies of various shapes and colors can also be produced by changing molds or pouring heads. Complete the quantitative injection and mixing of flavor, pigment and acid solutions online. Automated production can not only produce products of stable quality.

1. Automatic control of dissolution temperature, with the automation of separate control by PLC and touch screen

2. Storage tanks equipped with liquid level sensors are used to detect the liquid level of syrup

3. The bottom of the dissolution tank is equipped with a pneumatic valve and a pipe filter to prevent the syrup from adhering to the impeller pump

4. All pipelines are equipped with filtering devices

5. This weighing system ensures the accuracy of the ingredient ratio for each batch to guarantee the same quality of each batch of candies.

At this step, water, sugar and the mixture, glucose and pectin syrup will be weighed.

ZY-300 medium-sized gummy candy production line

Model :ZY300Q

Output :300kg/h

Although: According to the size of the grid

Hysteresis velocity :25-55n/min

Working environment requirements: Nirvana 20-25 ° C; Humidity: 55%, 20-25 ° C

Overall power :26kw/380v

The overall length of the machine is 20m

Total weight of the whole machine: 4,500 kg

Equipment process flow:

Dissolving sugar → Filtering → Boiling sugar → cooling → adding additives → Casting into shape → cooling → demolding → drying room → packaging → boxing

Control system

The gummy candy making machine is equipped with a programmable logic controller (PLC), which is a touch screen. It is equipped with an LED touch panel, which enables efficient and easy control.

The corresponding molds can be customized according to the desired shape of the gummy candies. By changing different molds, gummy candies of different shapes can be processed.

ZY-150 medium-sized gummy candy production line

Model :ZY150Q

Output :150kg/h

Although: According to the size of the grid

Hysteresis velocity :25-55n/min

Working environment requirements: Nirvana 20-25 ° C; Humidity: 55%

Overall power :16kw/380v

The overall length of the machine is 18 meters

Total weight of the whole machine :3000kg

Equipment process flow:

Dissolving sugar → Filtering → Boiling sugar → cooling → adding additives → Casting into shape → cooling → demolding → drying room → packaging → boxing

Characteristics

At the level of automation, you will achieve a reduction in labor costs.

The automatic feature of the machine leads to an increase in output.

Due to the touch screen and the PLC control panel for configuration, the monitoring and adjustment of production operations are simpler.

This machine is mainly made of stainless steel, so it is not easily contaminated.

The human-machine interface on the machine makes it easy to operate.

The maintenance cost is low, requiring only regular cleaning and lubrication of moving parts.

ZY-80 medium-sized gummy candy production line

Model :ZY150Q

Output :80kg/h

Although: According to the size of the grid

Hysteresis velocity :25-55n/min

Working environment requirements: Nirvana 20-25 ° C; Humidity: 55%

Overall power :10kw/380v

The overall length of the machine is 13 meters

Total weight of the whole machine :2000kg

Equipment process flow:

Dissolving sugar → Filtering → Boiling sugar → cooling → adding additives → Casting into shape → cooling → demolding → drying room → packaging → boxing

Small gummy machine

Small gummy candy machines are divided into fully automatic small gummy candy machines and semi-automatic small gummy candy machines. Fully automatic small gummy candy machines can be equipped with automatic feeding systems and automatic mold systems. Semi-automatic small gummy candy machines require manual mold changing and demolding during the pouring process.

ZY-ASC fully automatic small gummy machine

Name: Small Automatic Gummy Machine (Small Candy Pouring Machine)

Motor: Servo motor

Material: 304 stainless steel

Power input: 110/220V AC/50-60HZ

Power output: 24V DC/MAX.1.5KW

Maximum temperature: 100 degrees

It is applied to food, pills, candies, chocolates, etc

ZY-SSC semi-automatic small candy machine

Semi-automatic small candy machine

Machine model: GD20

The machine is driven by a cylinder and can only process solid glue. The mold needs to be changed manually.

Machine material: 304 stainless steel.

Nozzle: Pure copper

Electrical components: Siemens

Cylinder: Airtac

Temperature sensor: Omron

Voltage: 380V, 50HZ, 3PH

Pouring speed: 30 times per minute

Candy monomers: 1-10g

Hopper volume: 23 liters

The air consumption is 20CBM/min

Power: 7.2kw

Size: 800*800*1700mm

Starch mold colloid gummy candy casting production line

The starch mold gummy candy casting production line is an automatic large-scale gummy candy production line. It uses a powder tray for mold casting and can pour 720 gummy candies at a time. Easy to operate, stable in operation and high in output. The entire production line includes a boiling system, a color and seasoning system, a pouring system, a pressing mold system, a starch processing system, a starch recovery system, a drying system, and an oil and powder coating system.

Main equipment

Gummy candy boiling machine

The output is 700kg/h

Power: 7kw

The water consumption is 1800 liters per hour

The steam consumption is 600kg/h

The steam pressure is 0.7Mpa

The pressure of the compressed air is 0.6Mpa

Dimensions: 2000*1200*2450mm

Powder mold casting machine

Output: 1000kg/h

Power: 105kw

The pressure of the compressed air is 0.7-0.8Mpa

The consumption of compressed air is 300m ³ /h

The consumption of cold water is 315kg/min

The cold water temperature is 4°C

The size of the powder pan is 820*400*56mm

The machine occupies an area of 150 square meters

Features of the starch mold gummy candy casting production line

It has strong applicability and can produce the vast majority of gel gummy products such as starch gummy candies, gelatin, carrageenan and mixed gelatin.

Soft candy products of different shapes, colors and flavors can be produced simultaneously

A mature casting and demolding system provides customers with suitable products

Mature processing technology, convenient spare parts replacement, and a perfect after-sales service system

The production line can be customized to fully suit your operation.

Three-head starch mold gummy candy production line

The entire line includes boiling, automatic powdering, mold printing, pouring (which can be controlled by servo motors for sandwich pouring, left and right dual-color pouring, and top and bottom dual-color pouring), sugar and powder separation system, powder processing and powder recovery system.

Pouring is carried out in accordance with the customer's requirements through professional arrangement and design, enabling the customer to achieve the desired production effect and output volume. The production line adopts: automatic powder feeding on the powder tray and automatic sugar and powder separation technology in the processing of the powder tray.

The entire line is programmed and controlled by a PLC system, and the powder pan drive is driven and controlled by a servo motor. During the powder pan drive process, the conveying process can be separated into slow-start, high-speed conveying, and buffer braking technology. Under the premise of ensuring the stability of operation and the stability of the sugar holes in the powder pan after film pressing, the efficiency of the casting machine can be improved as much as possible.

Semi-automatic starch mold gummy production line

The entire line includes boiling, mold printing, powder coating, pouring (sandwich pouring, left and right two-color pouring, top and bottom two-color pouring can be adopted), sugar powder separation and powder recovery system.

Mold types (candy shapes) and applications

It is suitable for casting gummy candies of different shapes, gel gummy candies, pectin gummy candies, carrageenan gummy candies, various vitamin gummy candies, functional gummy candies, health product gummy candies, etc. What shape of candy is needed can be completed by customizing the corresponding mold

The working principle of the gummy candy machine

I: Raw material preparation

Prepare all the raw materials according to your recipe before running the gummy machine. Make sure the quantities of all ingredients are correct.

II: Cooking ingredients

Mix sugar, glucose and water in a dissolving pot for about 15 to 20 minutes to obtain the syrup you need. Transfer the mixture to a buffer tank.

Meanwhile, start cooking the next batch.

III: Online mixing of additives

The mixture flows to the online mixer for flavoring, coloring and acid addition, and then is pumped to the hopper of the casting machine. If you have two sets of blenders, you can mix mixtures of two different flavors and colors.

IV: Make gummy candies

At this stage, gummy candies of different shapes and colors will be formed by the casting machine and filled into the gummy candy molds. The weight of each gummy candy will be controlled by PLC.

V: Shaping and cooling

After being filled with the mixture, the mold will be transferred to the cooling tunnel. Depending on your gummy weight, they will continue to move in the cooling tunnel for 6 to 10 minutes. Then, after being transferred to the sugar coating or oil coating machine by the conveyor, the gummy candies are stored in the drying room and the moisture is discharged before packaging.