Solid (dangerous) waste incineration system

Hazardous waste refers to materials with hazardous characteristics, which have one or more hazardous characteristics such as toxicity, explosive, inflammability, corrosion, etc. At home and abroad, the disposal of hazardous waste is quite important. The current hazardous waste treatment methods mainly include incineration and landfill, among which the rotary kiln incineration treatment technology is currently widely used in the treatment of hazardous waste. It is becoming an important way of harmless treatment of hazardous waste.

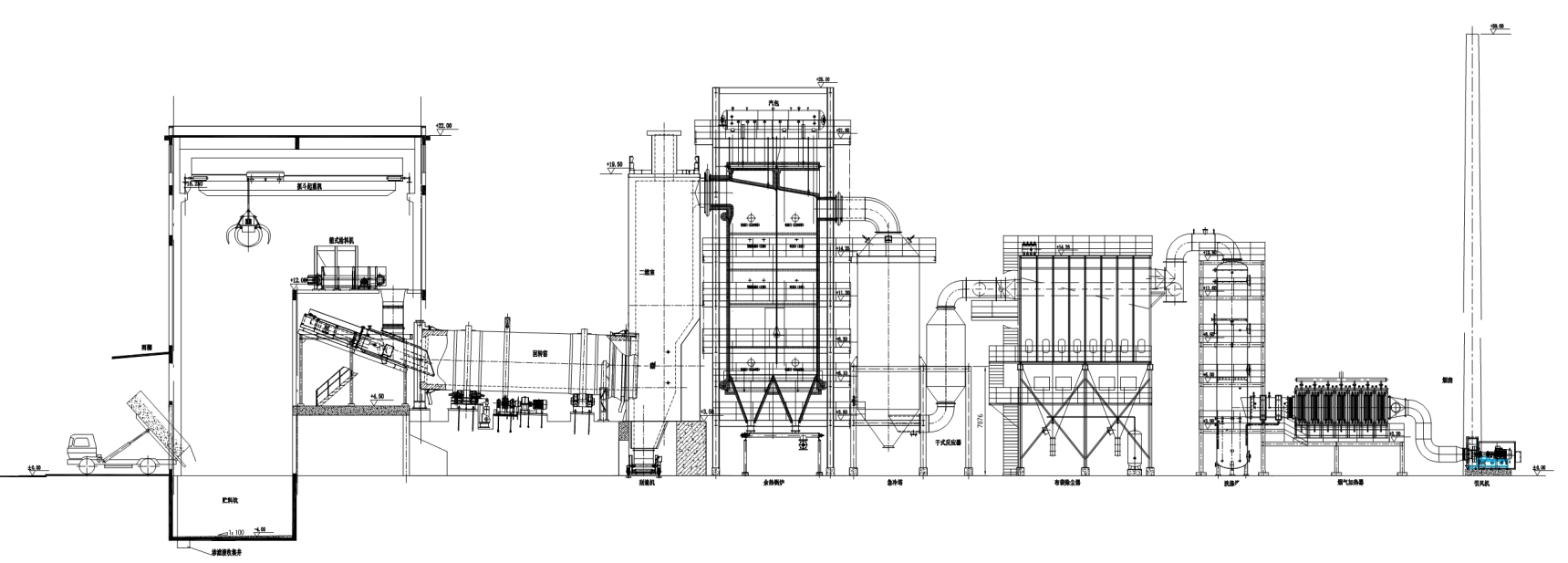

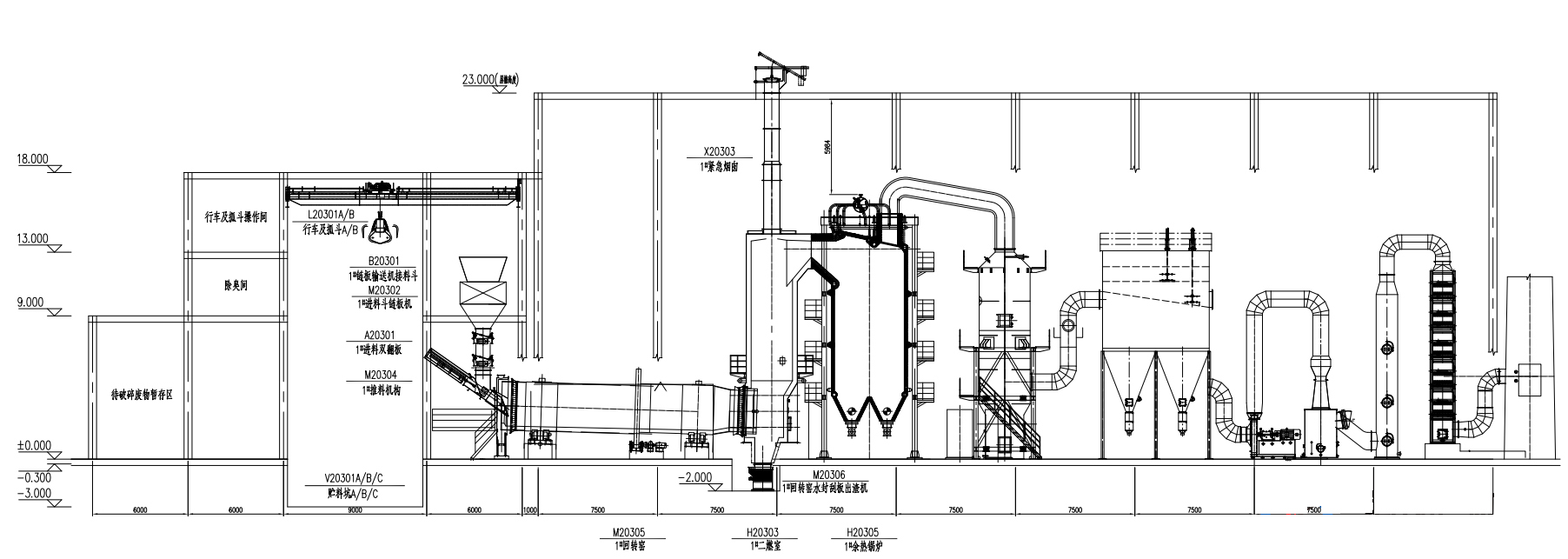

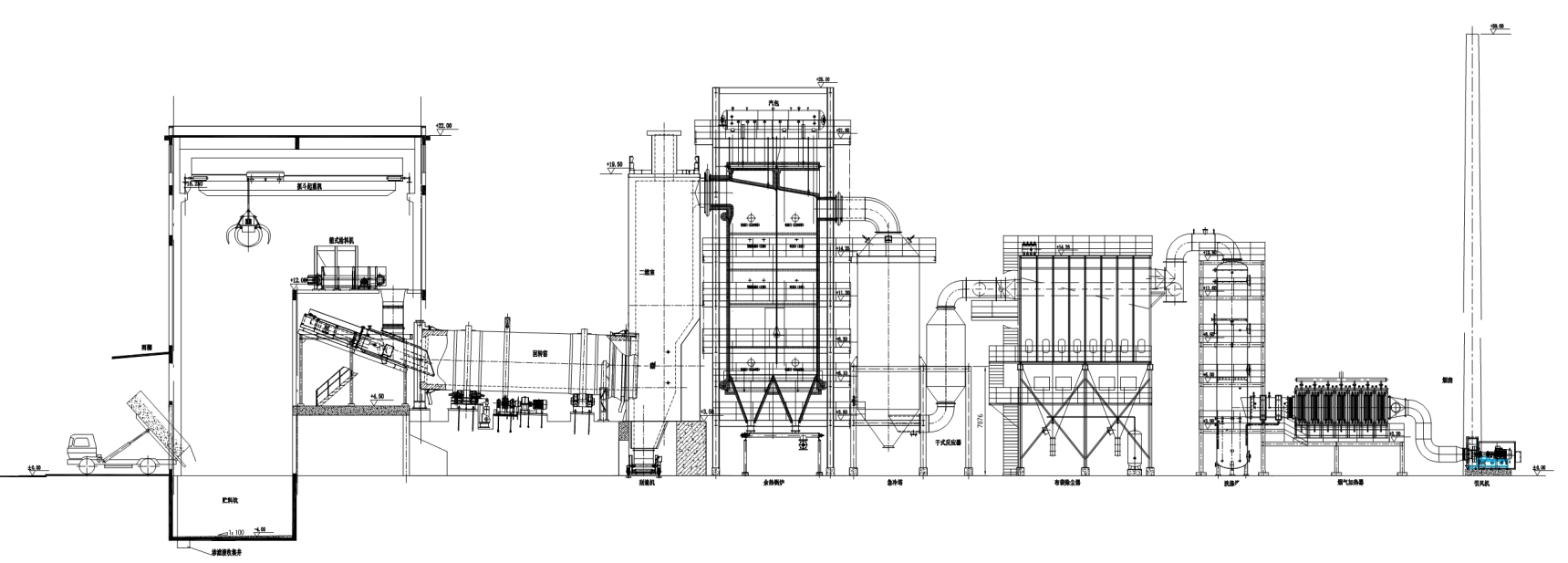

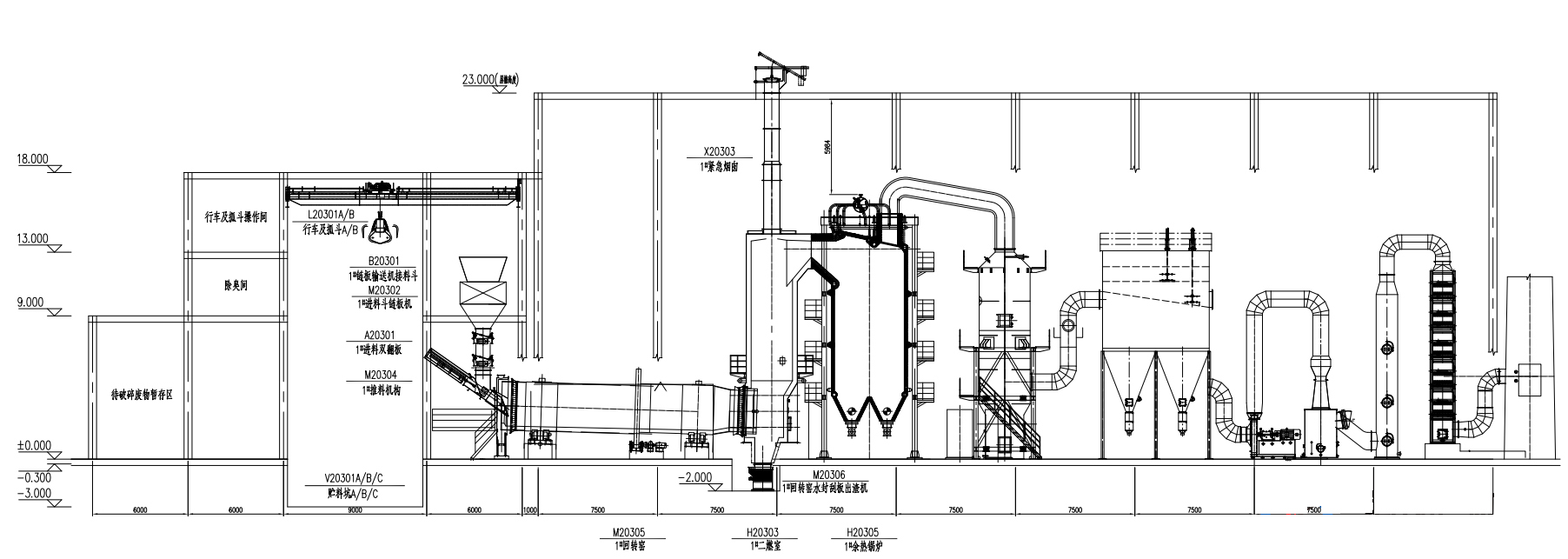

Main equipment: pretreatment and feed system, rotary kiln + secondary combustion chamber combustion system, waste heat recovery system, tail gas purification treatment system

Applicable materials: tailings, tailings, white mud, calcium carbide slag, aluminum ash, contaminated soil, municipal medical waste, domestic sludge, acid washing sludge and other materials

Application: industrial hazardous waste, medical waste, petroleum, chemical, pesticide and other industries of all kinds of solid waste, liquid waste and waste gas

Capacity: 10-120t/d

Outstanding advantage

1, Can simultaneously deal with waste water/waste gas/liquid waste three kinds of waste;

2, Waste heat recovery, produce benefits;

3. Wide application range, strong material adaptability, large processing capacity, strong moisture content resistance and other advantages.

Characteristics of rotary kiln incineration system

1, The incineration technology can not only meet all the environmental requirements of hazardous waste (medical waste) harmless treatment, but also the recommended technology for solving hazardous waste in our country.

2. Wide application range, strong material adaptability, large processing capacity, strong moisture content resistance and other advantages; The furnace heat load is large, the material is completely incinerated, enough to cope with the complete incineration of a large number of hazardous wastes, even if the calorific value and moisture content of the material have some fluctuations, it can be completely incinerated. It is suitable for incineration of comprehensive hazardous waste.

Characteristics of medical and industrial hazardous waste systems

1, can simultaneously deal with waste water/waste gas/liquid waste three kinds of waste;

2, liquid waste feed using micron atomization, combustion is complete, saving fuel consumption;

3, waste heat recovery, produce benefits;

4, DCS control, high degree of automation;

5. Wide application range, strong material adaptability, large processing capacity, strong moisture content resistance and other advantages;

6, the furnace heat load is large, the material incineration is thorough, enough to cope with the complete incineration of a large number of hazardous waste, even if the calorific value and moisture content of the material have some fluctuations, it can be completely incinerated. It is suitable for incineration of comprehensive hazardous waste.

Process flow

Pretreatment and feed system -- rotary kiln + secondary combustion chamber combustion system -- waste heat recovery system -- tail gas purification treatment system -- flue gas emission

Incineration system: including hopper, rotary kiln, secondary combustion chamber, and auxiliary equipment such as combustion aid and fan.

Waste heat recovery system: including waste heat boiler and boiler auxiliary system equipment.

Flue gas purification system: cool the flue gas in the incinerator and remove harmful substances, and discharge after meeting the emission requirements. Including quench tower, dust collector, scrubber, flue gas heater, active carbon supply system, ash and slag removal system.

Flue gas discharge system: including induced draft fan, chimney, etc.

| NO. | Specifications (m) | Processing capacity (t/d) | Speed (rpm) | Support number | Reduction type number | Motor type | power |

| 1 | φ2.2×9m | 20-30 | 0.2~2 | 2 | The mainZSY315-80 | The mainYVF3-200L1-6 | 18.5 |

| AuxiliaryZSY160-80 | AuxiliaryYE3-100L2-6 | 3 |

| 2 | φ2.6×10m | 30 | 0.15~1.5 | 2 | The mainZSY355-71 | The mainYVF3-225M-6 | 30 |

| Auxiliary:ZSY160-40 | AuxiliaryYE3-112M-4 | 4 |

| 3 | φ2.5×13m | 35 | 0.2~2 | 2 | The mainZSY355-63 | The mainYVF3-280S-6 | 45 |

| AuxiliaryZSY160-40 | AuxiliaryYE3-112M-4 | 4 |

| 4 | φ3.0×11m | 40 | 0.2~2 | 2 | The mainZSY355-56 | The mainYVF3-280S-6 | 45 |

| AuxiliaryZSY160-40 | AuxiliaryYE3-112M-4 | 4 |

| 5 | φ3.2×14m | 50 | 0.2~2 | 2 | The mainZSY400-56 | The mainYVF3-280M-6 | 55 |

| AuxiliaryZSY160-40 | AuxiliaryYE3-132S-4 | 5.5 |

| 6 | φ3.3×15m | 60 | 0.2~2 | 2 | The mainZSY400-56 | The mainYVF3-280M-6 | 55 |

| AuxiliaryZSY160-40 | AuxiliaryYE3-132S-4 | 5.5 |

| 7 | φ3.5×16m | 60 | 0.2~2 | 2 | The mainZSY400-50 | The mainYVF3-280M-6 | 55 |

| AuxiliaryZSY160-40 | AuxiliaryYE3-132S-4 | 5.5 |

| 8 | φ3.8× 16m | 50-70 | 0.1-1.1 | 2 | The mainZFY500-100 | The mainYVF3-280M-6 | 55 |

| AuxiliaryZSY160-25 | AuxiliaryYE3-132S-4 | 5.5 |

| 9 | φ4.0×14m | 80 | 0.1-1.1 | 2 | The mainZFY500-112 | The mainYVF3-280M-6 | 55 |

| AuxiliaryZSY160-25 | AuxiliaryYE3-132S-4 | 5.5 |

| 10 | φ4.2×16m | 100 | 0.1-1.0 | 2 | The mainZFY500-112 | The mainYVF3-280M-6 | 55 |

| AuxiliaryZSY160-25 | AuxiliaryYE3-132S-4 | 5.5 |

| 11 | φ4.5× 16m | 100 | 0.05-0.5 | 2 | The mainZFY630-200 | The mainYVF3-280M-6 | 55 |

| AuxiliaryZLY140-20 | AuxiliaryYE3-132S-4 | 5.5 |