The toffee production line includes the casting toffee production line, the stamping toffee production line and the extrusion toffee production line

1. Fully automatic toffee pouring production line

Model :ZY600T- Toffee Pouring Production Line

Model :ZY450T- Toffee Casting Production Line

Model :ZY300T- Toffee Casting Production Line

Model :ZY150T- Toffee Casting Production Line

2. Fully automatic die toffee production line

Fully automatic toffee production line

1.Fully automatic toffee filling production line

Cylindrical, spherical and fancy toffee production lines

3. Fully automatic extrusion toffee production line

Model :ZY300E- Extruded Toffee Production Line

Model :ZY600E- Extruded Toffee Production Line

4. Block toffee production line

5. Crispy Toffee production line

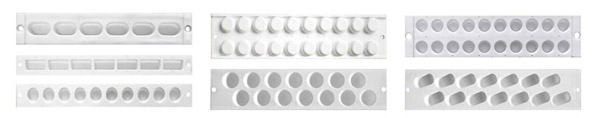

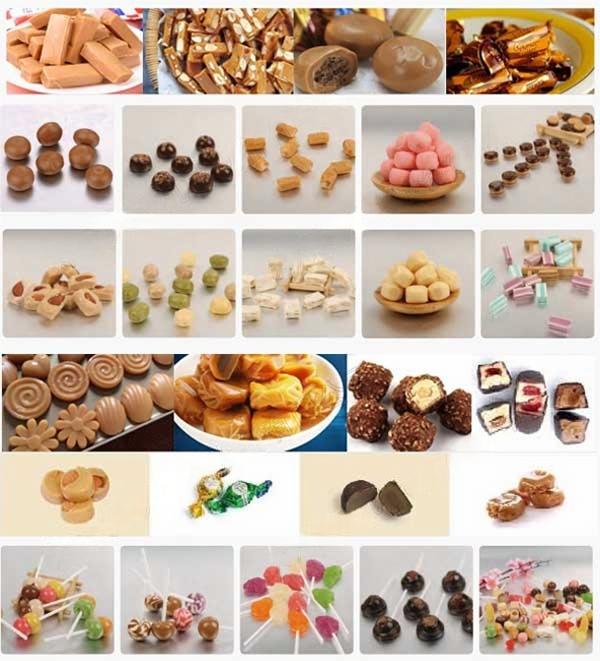

6. Toffee types (Toffee shapes) and Applications

7. Working Principle of Toffee Machine

8. Installation of the toffee production line

1. Fully automatic toffee pouring production line

This production line is manufactured by the company based on market demand and can meet the needs of various flavors and varieties of toffee. It is a kind of equipment for the continuous production of charred and fragrant candies.

It can produce high-quality single-color, double-color and filled toffee. Toffee of various shapes and types can also be produced by changing the molds and the corresponding demolding devices. Highly automated production can not only produce products of stable quality, but also save labor and occupy space, thereby reducing production costs.

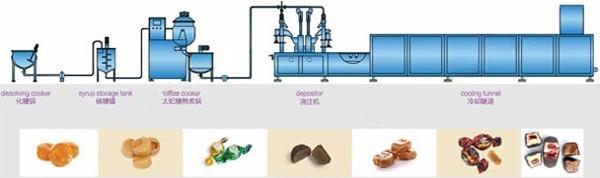

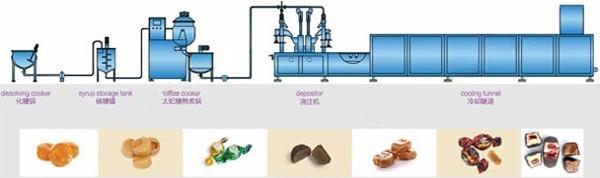

The processing flow of the toffee casting production line

Sugar dissolving pot - Sugar storage tank - Toffee boiling pot - pouring machine - cooling tunnel

Main equipment

Toffee boiling machine

This sugar boiling pot is specially designed and manufactured for the production of charred and fragrant candies. It features steam jacket heating and internal edge scraping and stirring, effectively preventing the sugar paste from charring during the boiling process. This machine can boil toffee, caramelie, Ecolamine and other candies.

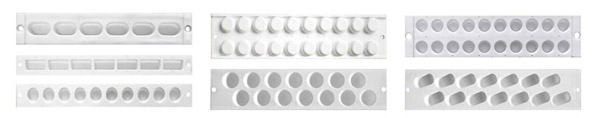

Mold

Customers can put forward their own design concepts, and we will complete the mold drawings. During the operation of the machine, just by changing different molds, candies of different shapes can be produced.

Pouring machine

This machine is composed of three parts: the pouring head, the mold and the cold cabinet. A standard configuration of a pouring head is a double hopper. Customers only need to replace the distribution plate and nozzle to produce filled toffee. This machine is controlled by a plc system. The setting and display of parameters such as temperature and pouring speed can all be controlled on the touch screen. Meanwhile, variable frequency speed regulation is adopted to control the accurate flow rate of the sugar liquid, ensuring the stability of the sugar paste quality.

Fully automatic toffee pouring production line

Fully automatic toffee pouring production line

This production line can produce single-color, double-color and sandwich toffees. Toffee of various shapes and types can also be produced by changing the molds and the corresponding demolding devices. Automated production can not only produce products of stable quality, but also save labor and occupy space, thereby reducing production costs.

The processing flow of the toffee casting production line

Sugar dissolving pot - Sugar storage tank - Toffee boiling pot - pouring machine - cooling tunnel

Characteristics

The PLC system of Mitsubishi is adopted to automatically control the time, temperature, pouring speed and pouring temperature of sugar boiling

The 10.7-inch touch screen can display the working status, temperature, pouring speed and other parameters of each part of the production line, making it easier for users to operate

The flow rate of the syrup is controlled by variable frequency speed regulation to ensure the quality of the produced products

The dynamic mixer completes the quantitative addition and mixing of essence, pigment and acid solution online

The optional chocolate quantitative filling system can produce chocolate-filled toffee

Candies of various shapes can be produced according to different molds

Non-standard machines can be customized according to the site requirements of customers

Model :ZY600T- Toffee Pouring Production Line

Output :600kg/h

The weight of the fruit: Depending on the size of the wood

Working environment requirements: Temperature 20-25 ° C; Humidity: 45%

Pouring speed :25- 55n/min

Overall power :38kW/380V

The total length of the line :22 meters

The total weight of the machine is 6,500 kg

Model :ZY450T- Toffee Casting Production Line

Output :450kg/h

The weight of the fruit: Depending on the size of the wood

Working environment requirements: Temperature 20-25 ° C; Humidity: 45%

Pouring speed :25- 55n/min

Overall power :34kW/380V

The total length of the line is 20 meters

The total weight of the machine is 5,500 kg

Model :ZY300T- Toffee Casting Production Line

Output :300kg/h

The weight of the fruit: Depending on the size of the wood

Working environment requirements: Temperature 20-25 ° C; Humidity: 45%

Pouring speed :25- 55n/min

Overall power :27kW/380V

The total length of the line is 20 meters

The total weight of the machine is 4,500 kg

Model :ZY150T- Toffee Casting Production Line

Output :150kg/h

The weight of the fruit: Depending on the size of the wood

Working environment requirements: Temperature 20-25 ° C; Humidity: 45%

Pouring speed :25- 55n/min

Overall power :18kW/380V

The total length of the line :18 meters

The total weight of the machine is 3,500 kg

2. Fully automatic die toffee production line

Toffee production line

The advantages of the toffee stamping production line

1.The chain forming machine has a fast stamping speed, good product quality, and the sandwich content can reach over 30%

2.The batch boiling machine, when equipped with a cooling drum, can achieve a boiling pressure of up to 8kg

3.Replace the chain stamping die without pressure within five minutes

4.It can be combined with different boiling equipment to produce other stamping products

5.Mature processing technology and convenient replacement of spare parts

6.The production line can be customized to fully suit your operation.

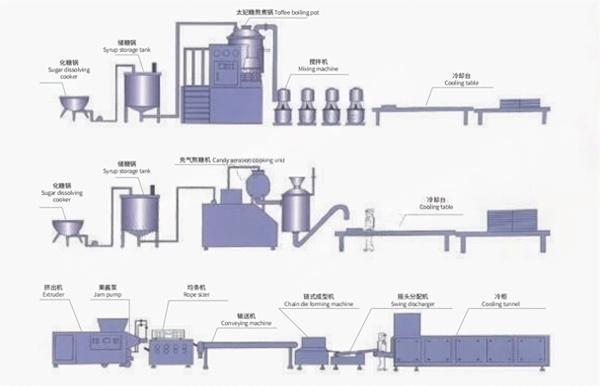

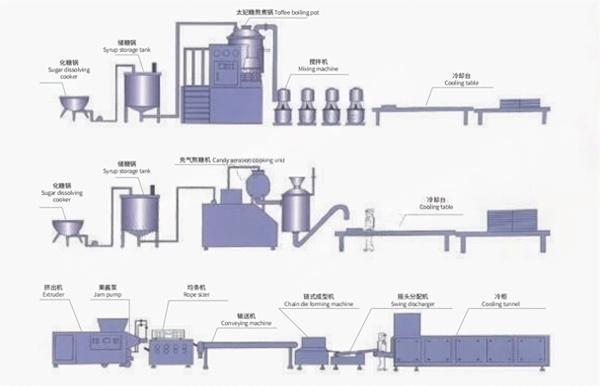

The process flow of toffee production line

Sugar dissolving (electric heating sugar boiling pot) - Storage tank - Vacuum gas-filled stirring milk candy sugar boiling machine (mixer) - cooling table - Slurry conveying machine - insulated rolling bed - drawing machine - conveyor belt - candy forming machine - cooling screen - packaging machine

Main equipment

Vacuum inflatable stirring milk candy boiling machine

Uses and features:

This unit is made of stainless steel. It rationally configures the heating, concentration, pulping, stirring and mixing of traditional inflatable candies through machinery, electricity, gas and instruments, and is a device for boiling inflatable candies. It is equipped with a computer PLC automatic control device and a touch screen operation. Its vacuum boiling and gas stirring can be automatically alternated. It can boil syrup with high or low gas, and a boiling pot can also be added as needed for the addition of auxiliary materials such as condensed milk. This machine has a relatively high control accuracy, so the syrup boiled by this machine has very good quality. This machine is suitable for inflating and boiling milk candies, nougat candies, fruit candies, marshmallows, sugar bar fillings and similar candies.

Technical parameters:

I. Sugar dissolving pot

Capacity: 300L

Weight: 280kg

Overall dimensions: 1100*1100*1700mm

II. Storage tanks

Capacity: 300L

Weight: 220kg

Dimensions: 740*740*1250mm

III. Boiling sugar in a pot

Model: CY-300

Output: 300kg/h

Steam pressure: 0.7mpa

Steam consumption: 160kg/h

Compressed air pressure: 0.6mpa

Compressed air consumption: < 0.25m³/min

Vacuum pressure: -0.06mpa

Vacuum pump power: 4kw

Main motor power: 17kw

Inflation pressure: < 0.3mpa

Overall dimensions: 2500*2500*3200mm

The total weight of the machine is 1500kg

Insulated roller bed drawing machine

Uses and features:

It is suitable for keeping sugar paste warm and pulling it into strips.

The operation is simple, it saves labor and improves efficiency.

Technical parameters:

The large capacity of the roller bed is 0.18m³

Extrusion speed: ≤25m/min

Total power: 6.3kw

Machine weight: 720kg

Overall dimensions: 3700*800*1700mm

Multi-functional candy forming machine

Purpose

It is suitable for the production of hard candies, sandy milk candies, toffee and filled candies, and can also be used in the production of crispy candies (the shape of the candies can be customized according to customer requirements), such as spherical, flat round, oval and various irregular shapes.

Characteristics

Stamping forming, smooth operation and high output.

Technical parameters

Production capacity :250kg/h

Total power: 2.4kw

Weight: 800kg

Overall dimensions: 2000 x 1100 x1300mm

Computerized multi-functional pillow packaging machine

It is suitable for the granular packaging of regular candies and some irregular-shaped candies, such as: rectangular, square, round, spherical, cylindrical, oval, etc.

Characteristics

Variable frequency speed regulation photoelectric tracking is simple to operate, runs smoothly, has a high speed and high output

Purpose

Suitable for granular packaging of candies and other solid regular items, such as: rectangular,

Technical parameters

High-speed fully automatic double twist packaging machine

Suitable for twisted packaging of spherical lollipops.

Characteristics

1.It is easy to operate, saves labor, runs smoothly, has low noise and is convenient for maintenance.

2. The main components adopt precision wheel intermittent division and CAM transmission mechanism to ensure that each action is accurate and in place.

3. The AC motor is equipped with a frequency converter to achieve stepless speed control and can be dynamically adjusted during operation.

4. Fully automatic PLC computer controller, photoelectric sensor detection, photoelectric detection, bidirectional tracking.

5. It has functions such as overload protection, leakage protection and membrane-free alarm.

6. The food contact parts are made of stainless steel, which has a good smoothness and is easy to clean.

7. Single or double-layer packaging film can be used, and an automatic feeding hopper can be configured.

Fully automatic toffee production line

The processing flow of toffee production line

1.Sugar dissolving pot - Sugar storage tank - Vacuum gas-filled sugar boiling machine - Cooling table - Conveyor - Insulated roller bed - Pulling machine - conveyor belt - Candy forming machine - cooling - packaging

2. Electric heating sugar boiling pot - mixer - Cooling table - Conveyor - Insulated rolling bed - Pulling machine - conveyor belt - Candy forming machine - Cooling - packaging

Sandwich toffee production line

Sugar dissolving pot - Sugar storage tank - Vacuum gas-filled sugar boiling machine - Cooling table - Conveyor - Insulated rolling bed - drawing machine - conveyor belt - Candy forming machine - Cooling - packaging

Cylindrical, spherical and fancy toffee production lines

The production line process flow of cylindrical, spherical and fancy toffee

Sugar dissolving - storage tank - Vacuum boiling pot - cooling table - insulated rolling bed - drawing machine - Rotary cutting machine - cooling screen - packaging machine

3. Fully automatic extrusion molding toffee production line

ZY300E- Toffee Production Line

It was introduced and developed in response to the fact that in recent years, with the improvement of people's living and consumption levels, the requirements for candy flavors have been evolving towards being more palatable, low in sugar, diverse in variety, and nutritious and health-preserving.

Vacuum sugar boiling and pneumatic stirring are automatically controlled alternately.

The inflatable stirring device ensures the improvement of product quality;

The production capacity can reach 300 kilograms per hour.

Chain molding can complete the production of milk candies of different shapes online.

It can produce regular milk candies, sandwich milk candies, toffee, Ecolane, etc.

Main equipment

Toffee boiling machine

This sugar boiling pot is specially designed and manufactured for the production of charred and fragrant candies. It features steam jacket heating and internal edge scraping and stirring, effectively preventing the sugar paste from charring during the boiling process. This machine can boil toffee, caramelie, Ecolamine and other candies.

Insulated roller bed drawing machine

Uses and features:

It is suitable for keeping sugar paste warm and pulling it into strips.

The operation is simple, labor-saving and highly efficient.

Technical parameters:

The maximum capacity of the roller bed is 0.18m³

Extrusion speed: ≤25m/min

Total power: 6.3kw

Machine weight: 720kg

Overall dimensions: 3700*800*1700mm

Extruder

Technical parameters

Production capacity (kg/h):200-300

Total power (kw):11

The dimensions of the divination shape (mm):1380x500x1480

Machine weight (kg):1100

Multi-functional candy forming machine

Purpose

It is applicable to the production of hard candies, sandy milk candies, toffee and filled candies, and can also be used in the production of crispy candies (the shape of the candies can be customized according to customer requirements), such as spherical, flat round, oval and various irregular shapes.

Characteristics

Stamping forming, smooth operation and high output.

Technical parameters

Production capacity: w250kg/h

Total power: 2.4kw

Weight: 800kg

Overall dimensions: 2000 x 1100 x1300mm

Chain stamping forming machine

The chain stamping forming machine is a stamping candy equipment, which can be used to produce filled or unfilled toffee and chewable gummy candies. This forming machine is equipped with a central drive device, and the forming chain is located on the carrier driver. Sugar shavings and dust can be easily collected in the space beneath the forming part. The chain forming mechanism is a special technique developed to increase the speed. With special design and material selection, the wear of parts during production can be significantly reduced.

Compared with the disc stamping forming machine, the products of the chain forming machine have the characteristics of more convenient clamping and toffee demolding.

Cooling tunnel

The cooling tunnel is a rapid cooling device designed to cooperate with high-yield candy forming production lines such as high-speed stamping forming machines. This equipment can provide cooling distribution for large quantities of candies in the cooling tunnel. Through the cyclic cooperation of the cooling unit and the conveying system, the candies will not split, deform, overlap, or adhere during the rapid cooling process. It is a large-scale candy cooling equipment.

Model :ZY-300E- Extrusion Toffee Production Line

Output :300kg/h

Production speed :1000pcs/min

Sugar weight: 7g of Shell material; central-filling: 2g

Steam pressure :0.2-0.6 mpa

Steam consumption :200kgs/h

Room temperature/humidity requirement :20-25 ° C/55%

Total power :22kW / 380V

The total length of the line :17 meters

The total weight of the machine is 8,000 kg

Model :ZY-600E- Extrusion Toffee Production Line

Output :600kg/h

Production speed :1000pcs/min

Sugar weight: 7g of Shell material; central-filling: 2g

Steam pressure :0.2-0.6 mpa

Steam consumption :300kgs/h

Room temperature/humidity requirement :20-25 ° C/55%

Total power :35kW / 380V

The total length of the line :19 meters

The total weight of the machine is 9,000 kg

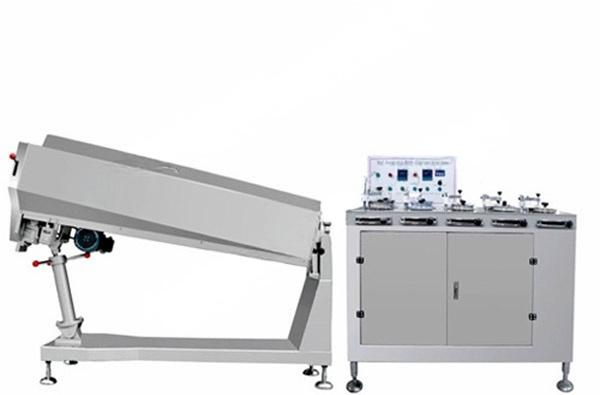

4. Block toffee production line

Block toffee production line

Technical parameters

Flattening machine

Total power (kw):1-5

Overall dimensions (mm):1675 x 788 x 1255

Machine weight (kg):560

Conveying cabinet

Total power (kw) : 0.75

Overall dimensions (mm):5000 x 788 x 1405

Machine weight (kg):560

Forming machine

Production capacity (kg/h):200-300

Total power (kw) : 1.5

Overall dimensions (mm):1850x798x1405

Machine weight (kg):400

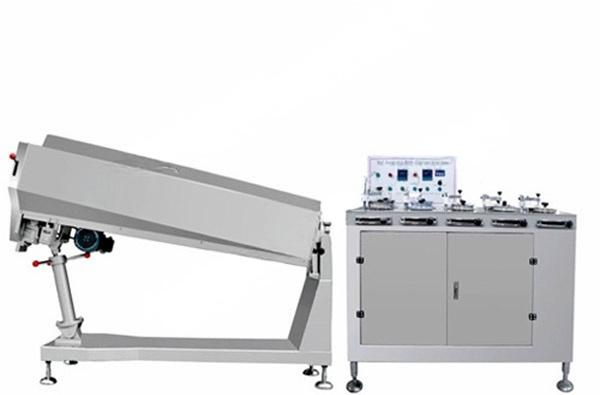

Vibrating screen

Total power (kw) : 0.37

Overall dimensions (mm):1210x450x530

Machine weight (kg):80

Uses and Characteristics

This production line is a complete set of equipment for manufacturing block products according to the needs of candy manufacturers. It can produce milk candies. The grain products with dissolved white sugar as the binder have the characteristics of high output and low labor intensity. This production line is composed of six radial beds, a flattening machine, a cooling conveying cabinet, a sugar bar forming machine, a cooling vibrating screen, etc. The main equipment is equipped with variable frequency speed control, featuring a reasonable structure and convenient operation and maintenance.

5. Crispy Toffee Production Line

Crispy toffee production line

This production line is suitable for the production of toffee crisps. This equipment is composed of a mixer, an extruder, six flattening machines, a forming machine, a cooling and conveying cabinet, an automatic granulator, a gum base oven and a coating machine, forming a fully automatic production line. It can produce candies of various shapes (such as square, rectangular, sheet, etc.). The whole machine is reliable in production, flexible and easy to operate, and has a high degree of automation. It is a device for producing crispy toffee.

The production process flow of crispy toffee

Mixer - Extruder - six-pass flattening - Forming machine - Cooling conveying cabinet - Automatic granulator - Adhesive base - Oven - Coating machine - Packaging machine

Main technical parameters of the production line

Production speed :500-600 kilograms per hour (kg/h)

Adjustable range of sugar shape: Bean shape: 6mm-22mm; Square: 6mm-30mm

Overall dimensions: 22000x1800x1750mm

Total power efficiency :75 kw

Power supply :380V/50HZ, 200V-240V/60HZ

The total weight of the machine is 11,000 kg

Main technical parameters of the single machine

Automatic feeding/dust removal crusher: Power :17kw, Dimensions :3500x1300x2200 mm, Weight :400 kg

Rubber-based oven: Power :18kw, Dimensions :1600x600x1700mm, Weight :300kg

Mixer -100L: Power: 20 kw, Dimensions :2300x860x1550 mm, Weight :1500 kg

Mixer -200L: Power: 24kw, Dimensions: 2650x1000x1650mm, Weight: 2000kg

Extruder - Single color: Power: 15kw, Dimensions: 2500x900x1500mm, Weight: 1000kg

Extruder - Two-color: Power :22 kw, Dimensions :2600x1150x1500 mm, Weight :2200 kg

Six-channel flattening: Power :5 kw, Dimensions :5100x950x1880 mm, Weight :2000 kg

Forming machine: Power: 2.2kw, External dimensions: 1800x780x1650mm, Weight :800 kg

Cooling conveyor cabinet -600 Width: Power :20 kw, external dimensions :8850x1900x1850 mm, Weight :2500 kg

Cooling conveyor cabinet -800 Width: Power :22 kw, external dimensions :8850x2100x1850 mm, Weight :2700 kg

Automatic bud separation and screening machine: Power :3 kw, external dimensions :2200x1000x1400 mm, Weight :350 kg

Sugar coating machine: Power :2 kw, Dimensions :1050x1050x1600 mm, Weight :350 kg

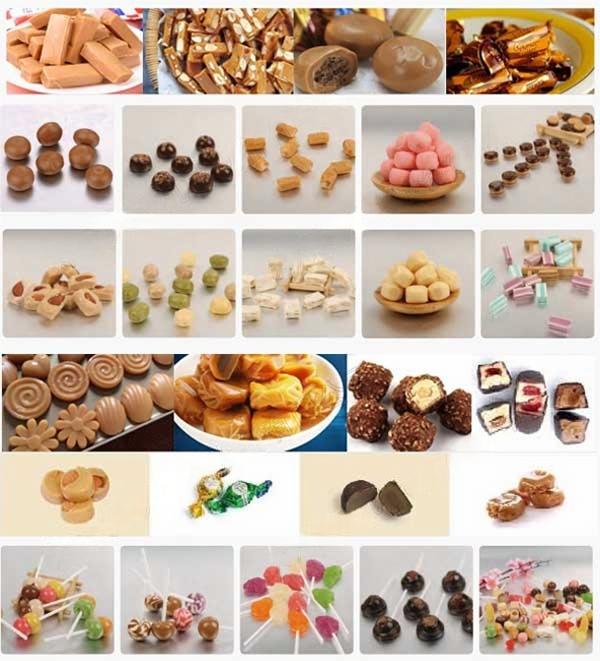

6. Toffee types (Toffee shapes) and Applications

It is suitable for pouring and punching out toffee of different shapes

7. Working Principle of Toffee Machine

1.Components of the casting molding machine: conveyor belt, model tray, sugar injection nozzle, sugar pouring pump, storage tank, cooling device. During the mold casting process, when the boiled sugar paste is still in an active state, the liquid sugar paste is quantitatively injected into the continuously running model tray, then rapidly cooled and shaped. After that, it is separated from the model tray and sent to the packaging machine along the conveyor belt for packaging.

2. Continuous stamping forming: When the sugar dough cools to an appropriate temperature, stamping forming can be carried out. If the temperature is too high, the sugar body will be too soft and difficult to shape. Even if sugar blocks are formed, they are prone to sticking together or deforming. If the temperature is too low, the sugar dough will be too hard, and the formed sugar grains are prone to fuzz, darkening, and missing edges and corners. The suitable temperature for stamping forming is 80-70℃. At this temperature, the sugar dough has plasticity. Stamping forming takes advantage of the characteristics of the sugar dough at this temperature range. The sugar dough is stretched into strips by a drawing machine or manually and then enters the forming machine for stamping forming.

When performing stamping forming, it is necessary to pay attention to the temperature and relative humidity in the forming workshop as well as the temperature of the die surface of the forming machine; otherwise, it is easy to cause broken bars or adhesion of the machine tools. The temperature in the molding chamber should not be lower than 25℃ and the relative humidity should not exceed 70%.

3. Extruded toffee: This production line is composed of a mixer, an extruder, a forming machine, a cooling and conveying cabinet, an automatic granulator, a gel base oven and a coating machine, forming a fully automatic production line. It can produce toffee of various shapes (such as square, rectangular, sheet, etc.). The whole machine is productive and reliable, easy and flexible to operate, and has a high degree of automation.

8. Installation of the toffee production line

We will send engineers to help you install the machine