VOCs exhaust gas treatment system

Our company entered the VOCs treatment industry, in the treatment of organic waste gas, actively research and develop, improve the process, and constantly explore, the treatment of VOCs organic waste gas generated by the spraying industry, the waste gas treatment system adopts the current advanced, environmental protection, efficient, energy-saving activated carbon adsorption concentration + catalytic combustion + heat storage and utilization of CO process technology route for treatment, discharged after reaching the standard. It has been praised by the owners.

The main pollution factors of this project are benzene, toluene, xylene and so on. Combined with the workshop painting process and in order to achieve higher treatment efficiency, the organic waste gas in this scheme is to be treated by the scheme of "dry filter + activated carbon adsorption concentration + catalytic combustion", which has the advantages of stable operation, high treatment efficiency and energy saving.

VOC concentration: ≤300mg/m³

VOC components: benzene, toluene, xylene, non-methane total hydrocarbons, etc

Applicable industries: footwear, printing and packaging, furniture, painting, electronics manufacturing and other industries pollution problems

Outstanding advantage

After scientific calculation and engineering experience, the fixed spray booth designed air volume of 45000m3/h, followed by the use of dry paint mist filtration system to filter the particles in the paint mist, the pretreatment of organic waste gas by activated carbon adsorption concentration + catalytic combustion technology route for treatment, after reaching the standard of high altitude discharge. After treatment, the total non-methane hydrocarbon in the waste gas is less than 40mg/m³; Benzene less than 1mg/m³; Toluene and xylene combined are less than 20mg/m³.

Advantages of VOCs waste gas treatment system:

1, low combustion temperature, achieve flameless combustion, save energy, no NOX generation, will not cause secondary pollution;

2, combustion efficiency purification efficiency is high, can achieve more than 98% purification efficiency;

3, safe and reliable: adopt a variety of safety measures and automatic detection system to ensure the normal and safe operation of the system.

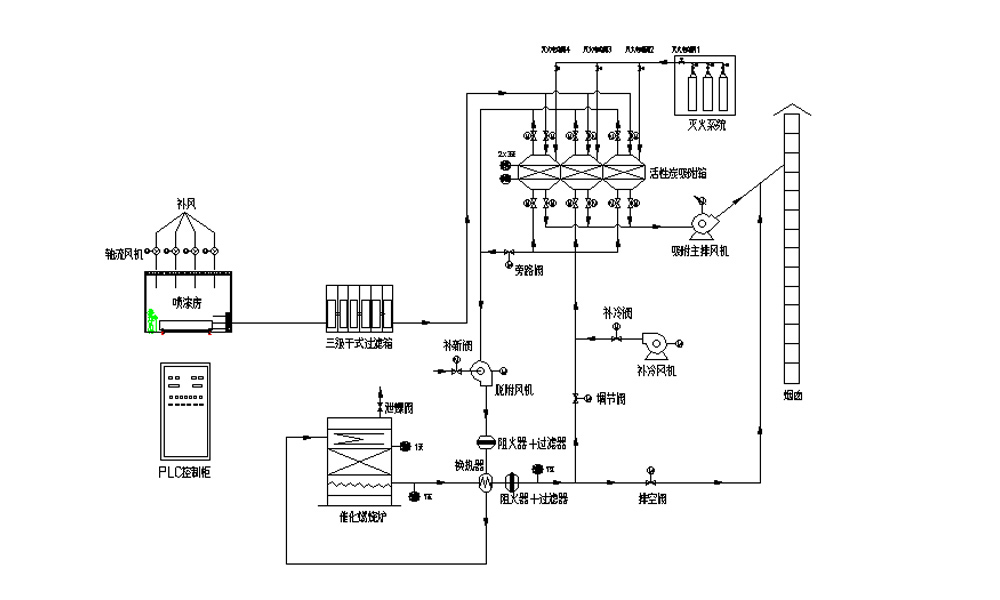

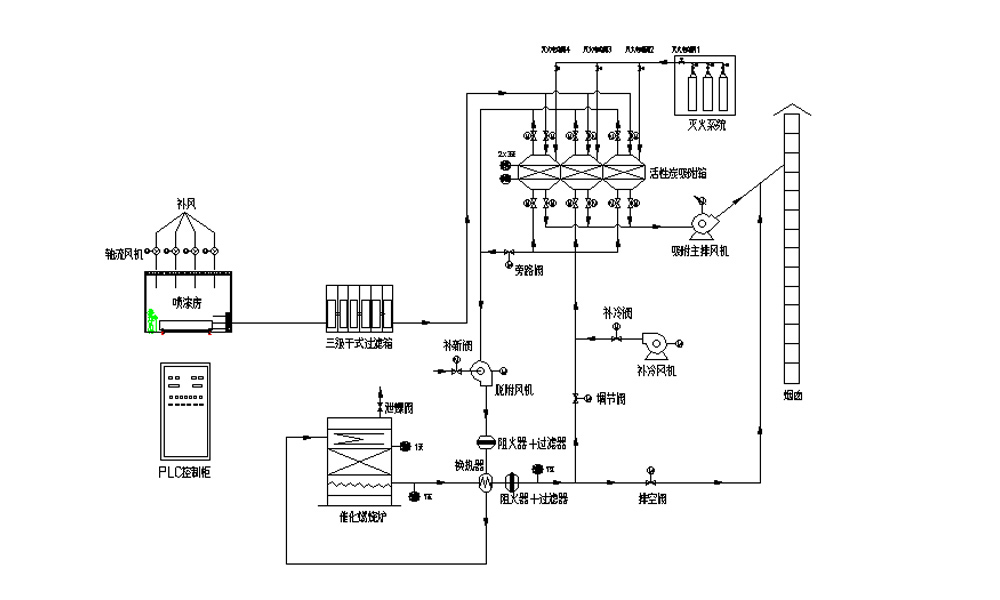

Process flow

Activated carbon catalytic combustion equipment is to effectively combine the advantages of activated carbon and catalytic combustion furnace. When the adsorption is saturated, the catalytic combustion equipment is started, and the hot air is used to locally heat the activated carbon adsorption bed. When the catalytic combustion reaction bed is heated to 250 ° C and the activated carbon adsorption bed locally reaches 60 ~ 110 ° C, the high concentration of desorbed waste gas can be oxidized and decomposed in the catalytic reaction bed. The high-temperature gas after the reaction is transferred by the heat exchanger, and part of the gas after the heat transfer is sent again to the activated carbon adsorption bed for desorption, and the other part is directly discharged.

The process mainly uses the catalyst, the waste gas under the action of the catalyst oxidation reaction, to produce non-toxic and odorless carbon dioxide (CO2) and water (H2O); Its unique heat exchange system ensures the effective recovery of waste heat. When the concentration of waste gas reaches a certain level, the heat exchange system can heat the organic waste gas to the starting temperature of the catalytic oxidation reaction, without electric heating, and treat the organic waste gas through its own heat balance.

The device is to introduce concentrated organic waste gas into the main equipment. After the organic waste gas is separated from the activated carbon layer by the internal heating device, it is decomposed into water and carbon dioxide by the action of the catalyst, and the energy is released at the same time, and the energy is replaced by the heat exchange device for maintaining the energy of the spontaneous combustion of the equipment.

When the temperature of the catalytic bed reaches 250 ~ 300℃, the catalytic combustion bed begins to react, and the hot air generated by the exhaust gas combustion is recycled, at this time the electric heating stops, no external heating is required, single bed desorption, desorption time is 2~3 hours, the set time activated carbon adsorption box automatically switches desorption. The internal ceramic honeycomb precious metal catalyst has a service life of 8,000 hours. The whole desorption system adopts multi-point temperature control to ensure the stability of desorption effect.

Technical parameter

Technical parameter

| NO. | Name | Technical data | Unit |

| 1 | Treated air volume | 45000 | m³/he |

| 2 | VOC concentration | ≤300 | mg/m³e |

| 3 | VOC component | Benzene, toluene, xylene, etc |

|

| 4 | Intake temperature | 40 | Ce |

| 5 | Relative humidity | 80% |

|

| 6 | Work mode ↵ | lull |

| 7 | Waste gas treatment technology | Dry filtration pretreatment + activated carbon adsorption concentration + catalytic combustion |

Technical parameter

Technical parameter