Sugarcane/beet sugar production line

Complete sets of equipment for deep processing of sugarcane and beet grains, white granulated sugar production lines, complete sets of machinery for sugar syrup and rock sugar, factory construction solutions for sugarcane, beet, white sugar, rock sugar and syrup production lines, cases of sugarcane machinery, beet machinery, rock sugar, syrup and white sugar machinery

The process of making white granulated sugar, crude sugar and other products from sugarcane through procedures such as juice extraction, purification, evaporation, crystallization, honey separation and drying. The characteristics of sugarcane, the chemical composition and properties of sugarcane juice have a significant impact on the sugar-making process and serve as the basis for selecting production methods and process conditions.

Extract juice

The methods for extracting sugarcane juice from sugarcane include the pressing method and the leaching method. The pressing method is a technique for extracting sugarcane juice from sugarcane through the combination of pretreatment and pressing equipment with an impregnation system.

Sugarcane pressing method

The principle of extracting juice by pressing mainly involves cutting sugarcane into thread-like and sheet-like materials and feeding them into a press. Under the pressure of the press roller and oil pressure, the cell walls of the sugarcane cells filled with juice break. As the materials are compressed and the cells are flattened, the juice is discharged simultaneously. The bagasse discharged from the press and beginning to expand is impregnated with water or diluted juice by means of the impregnation system to dilute the sugar within the cells and extract more sugarcane juice.

purity

By means of the chemical and physicochemical effects of detergents and heating, and through solid-liquid separation methods, various non-sugar substances that affect the crystallization of sucrose in the mixed juice are removed to obtain a clean juice with a lower color value, clarity and purity.

The process of sugar production from sugar beets includes procedures such as juice extraction, purification, evaporation, crystallization, honey separation and drying. Among them, the technological processes of the last four procedures are basically the same as those of sugar production from sugarcane

It is basically the same as sugar production from sugarcane.

Extract juice

First, the sugar beets need to be pre-treated and shredded, and then the leachate is obtained.

Pre-treatment

Sugar beets need to undergo pretreatment such as conveying, impurity removal and washing before processing. The sugar beets to be processed are stored in the sugar beet cellar of the sugar factory. Under the cellar, there is a flow channel with a long cross-section and rounded corners at the bottom leading to the sugar processing workshop.

Washed sugar beets are usually transported by bucket elevators or belt conveyors to remove iron by magnetic force and then sent into the storage bucket of the shredder. Commonly used shredders include flat disc type and centrifugal type. The flat disc shredder is mainly composed of a vertical shaft and a rotating knife disc.

Extract the exudate

The process of extracting sugar from shredded vegetables using water as the solvent is called exudation. The sugar-containing water solution obtained is called exudation juice, and the shredded vegetables after sugar extraction are called waste meal.

During the leaching process, it is required to extract the sugar from the shredded vegetables to a certain extent with a certain amount of water, while the non-sugar content is retained entirely in the waste meal.

Purity: The presence of non-sugar in the exudate can cause difficulties in processing, affect the quality of sugar products, and increase the amount of waste honey and sugar loss.

Complete sets of equipment for deep processing of sugarcane and beet grains, white granulated sugar production lines, complete sets of machinery for sugar syrup and rock sugar, factory construction solutions for sugarcane, beet, white sugar, rock sugar and syrup production lines, cases of sugarcane machinery, beet machinery, rock sugar, syrup and white sugar machinery

White sugar processing equipment production line

According to the different sugar-making processes, sugarcane white granulated sugar can be divided into sulfide sugar and carbonized sugar.

Sugar sulfide

The sugar disulfide - sulfurous acid clarification technology is a method for purifying and decolorizing sugarcane juice and syrup in the white granulated sugar production industry. Due to its characteristics such as few equipment, relatively simple process flow and convenient management, this clarification technology has been applied in China's sugar industry.

Carbonized sugar

The characteristics of carbonized sugar - carbon process sugar: The method of clarifying sugarcane juice with lime and carbon dioxide as clarifying agents is called the carbonation process. The sugar produced by the carbonation process is called carbonized sugar, also known as carbon (acid) process sugar. The production of sugar by the carbonic acid method removes more non-sugar substances than by the sulfurous acid method. The finished sugar produced has a higher purity, a lower color value, less sulfur content, and can be stored for a long time without discoloration.

Rock sugar is an ice-like crystal made by boiling white granulated sugar. It is produced by redissolving and cleaning sucrose and then recrystallizing it. It comes in two types: single crystals and polycrystals, and is transparent or semi-transparent.

Because its crystals are like ice, it is called rock sugar. Naturally formed rock sugar comes in colors such as white, slightly yellow, and light gray.

Rock sugar can be produced from refined syrup, an intermediate product in the refining workshop of a sugar refining factory, or from white granulated sugar. It is made through the processes of re-dissolution, purification and recrystallization. It comes in colors such as white, slightly yellow, slightly red and deep red, and its crystals are like ice, hence the name rock sugar. Because the component of rock sugar is glucose with crystalline water, which is the same as the component that white sugar decomposes in the body, it can replace white sugar. And because of its high purity and its own unique effects.

1.Single crystal rock sugar

Put the white granulated sugar into an appropriate amount of water and heat it to dissolve. After filtration, input it into the crystallization tank to make the sugar solution supersaturated. Add the crystal seeds for crystal cultivation. When the crystals grow large, take them out for dehoney removal and centrifugal drying. After ventilation and drying, sieve them, grade them and package them for factory release.

2. Polycrystalline rock sugar

It is an irregular crystalline rock sugar produced by traditional techniques. According to different production processes, it can be further classified into the hanging thread method for rock sugar (the finished product is divided into ice columns and ice edges, and there may be impurities such as cotton thread and paper scraps) and the basin crystallization method (the rock sugar crystallizes along the crystallization basin, and the finished product is relatively pure). It is classified by color into white rock sugar, yellow rock sugar and amber rock sugar (gray).

Introduction to individual equipment of the production line:

1.Integrated drying and cooling machine for refined sugar

Processing capacity: 100- 50,000

Application scope: Sugar production from sugar beets

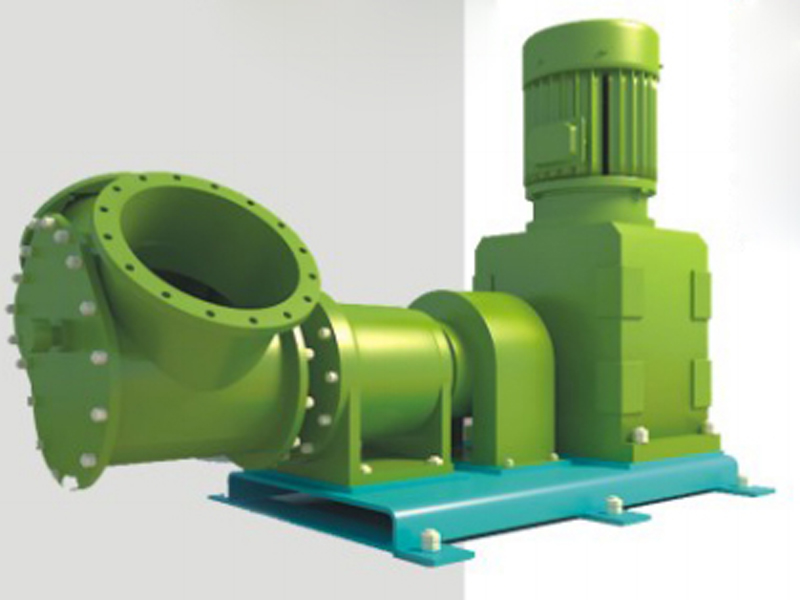

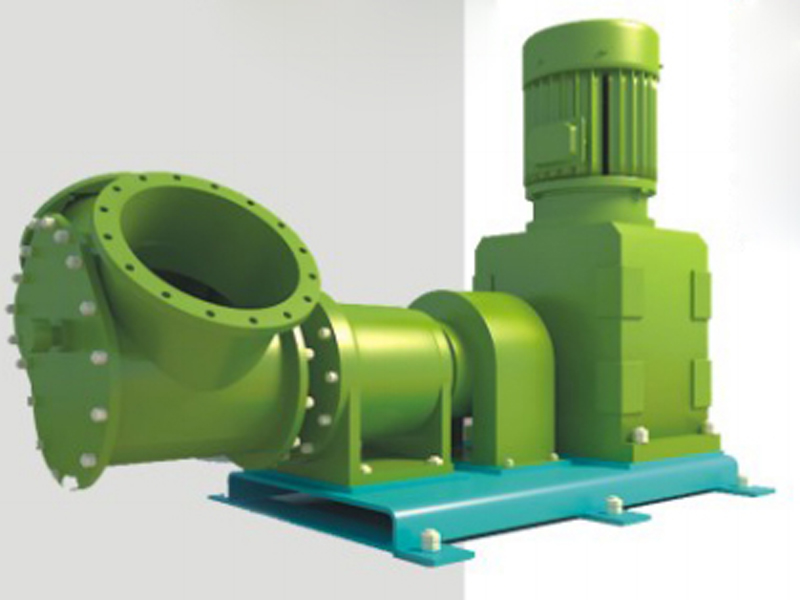

2. Sugar paste pump

Processing capacity: 100- 50,000

Application scope: Sugar beets

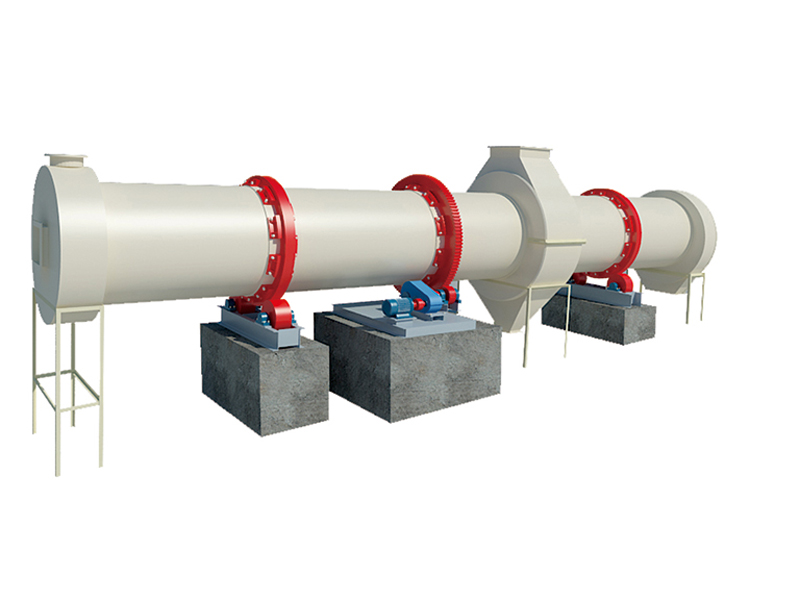

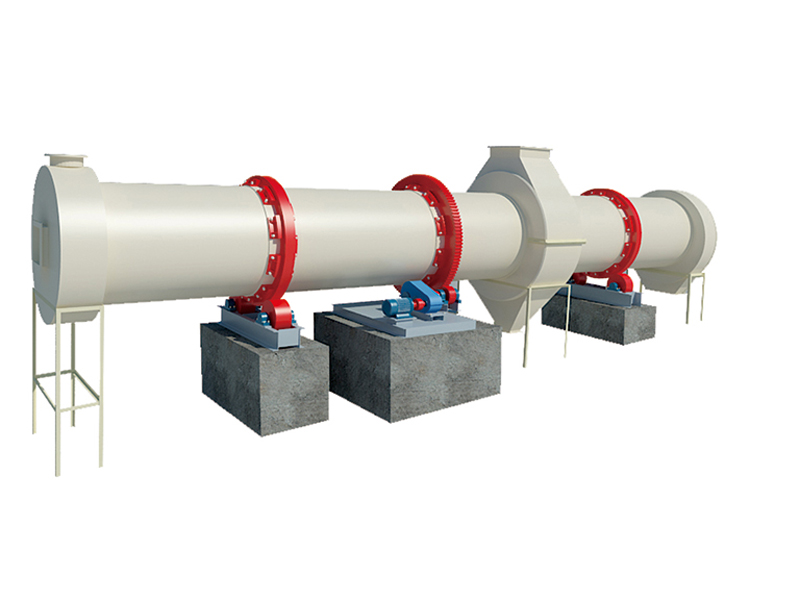

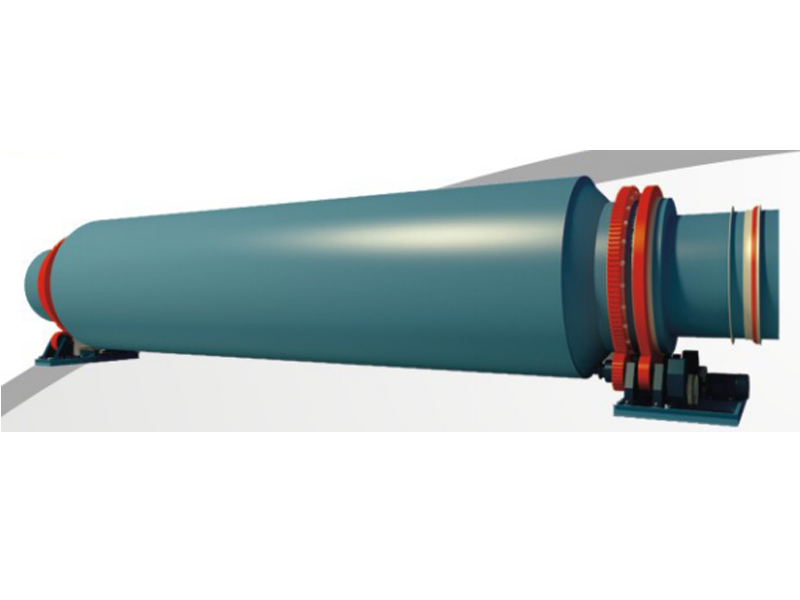

3.Sugar beet waste meal drum dryer system

Processing capacity: 100- 50,000

Application scope: Sugar beets

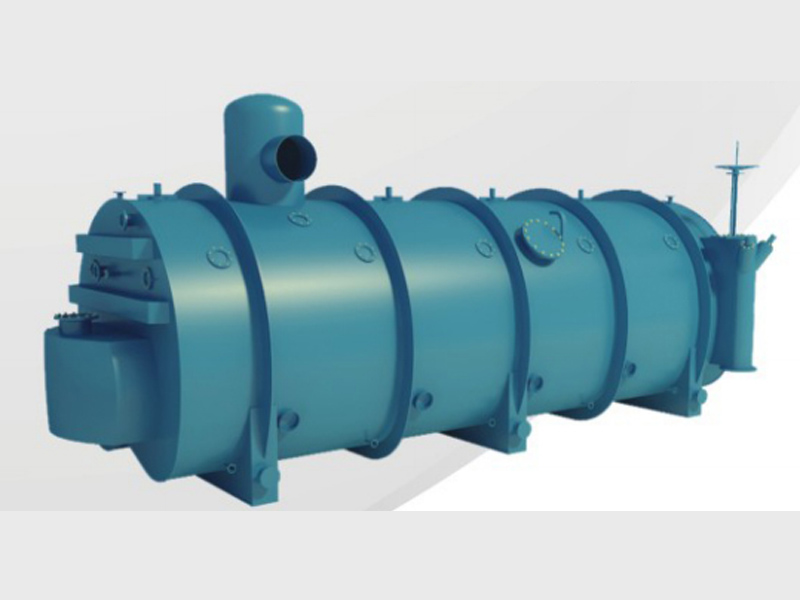

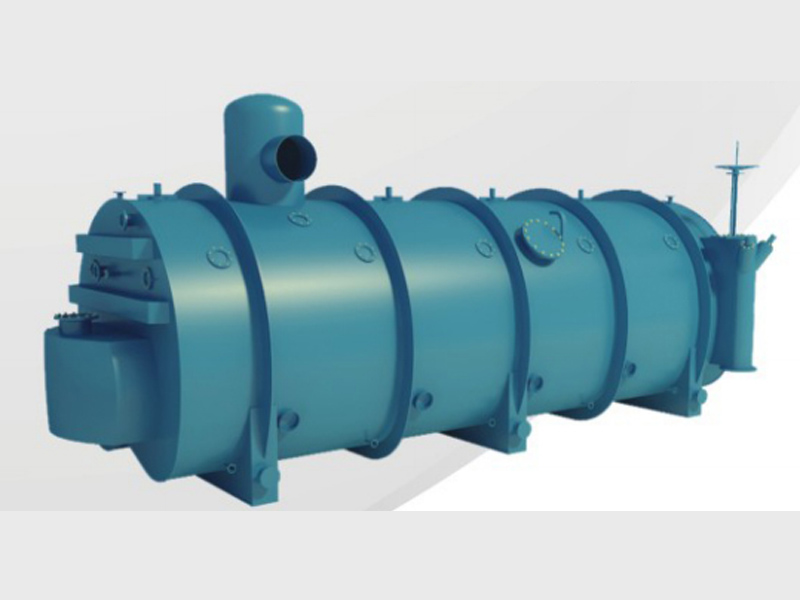

4.Horizontal continuous crystallization tank

Processing capacity: 100- 50,000

Application scope: Sugar production from sugar beets

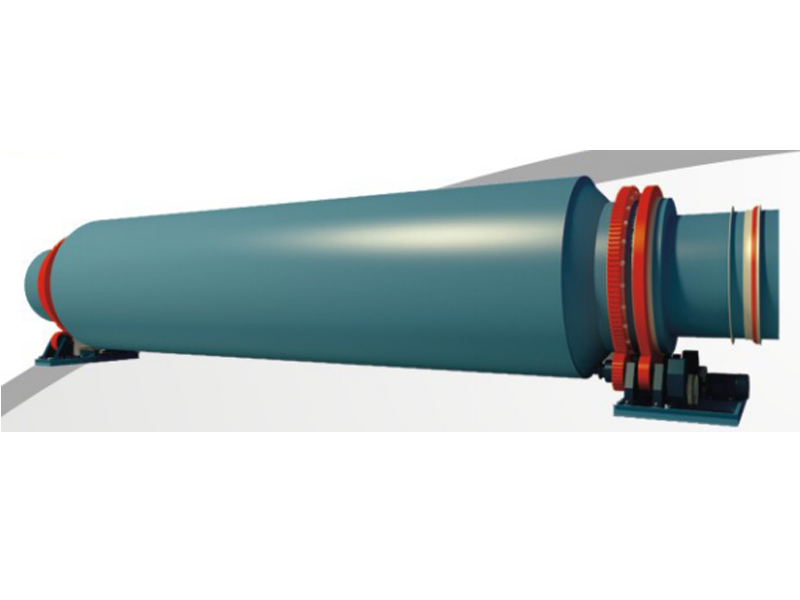

5.Sugar beet exudator

Processing capacity: 100- 50,000

Application scope: Sugar beets

6.Sugar beet stacker

Processing capacity: 100- 50,000

Application scope: Sugar beets

7.Crystallization tank

Processing capacity: 100- 50,000

Application scope: Sugarcane sugar, beet sugar

8.Drum dryer

Processing capacity: 100- 50,000

Application scope: Sugarcane

9.Fully automatic centrifuge

Processing capacity: 100- 50,000

Application scope: Sugarcane sugar beet

10.Vertical crystal aid machine

Processing capacity: 100- 50,000

Application scope: Sugarcane sugar beet

11. Reheater

Processing capacity: 100- 50,000 tons

Application scope: Sugarcane

12. Continuous sugar boiling pot

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

13.Forced circulation crystallization tank

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

14.Falling film evaporation tank

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

15.Evaporation tank

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

16.Syrup filter

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

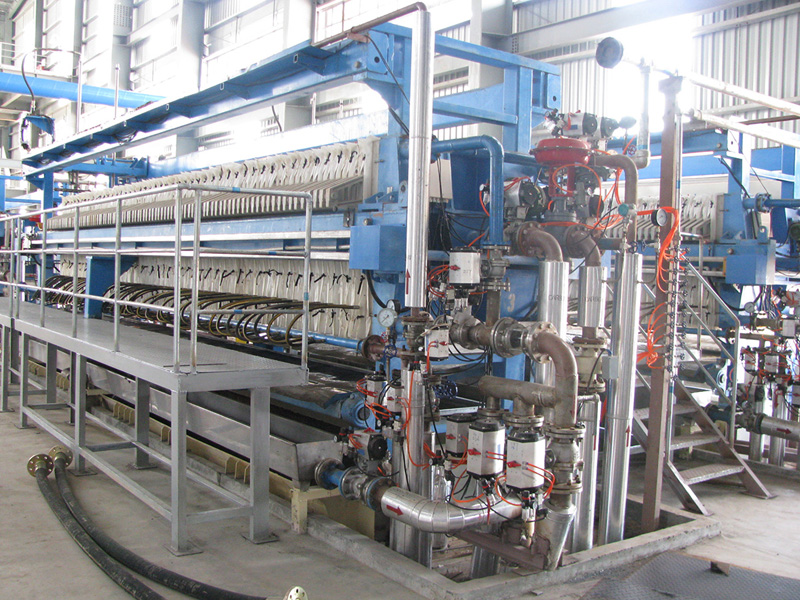

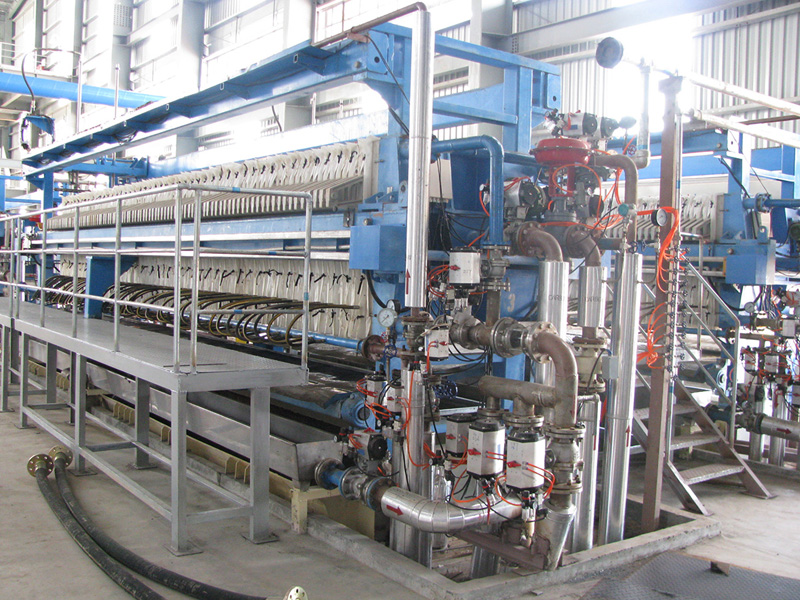

17.Fully automatic diaphragm filter press

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

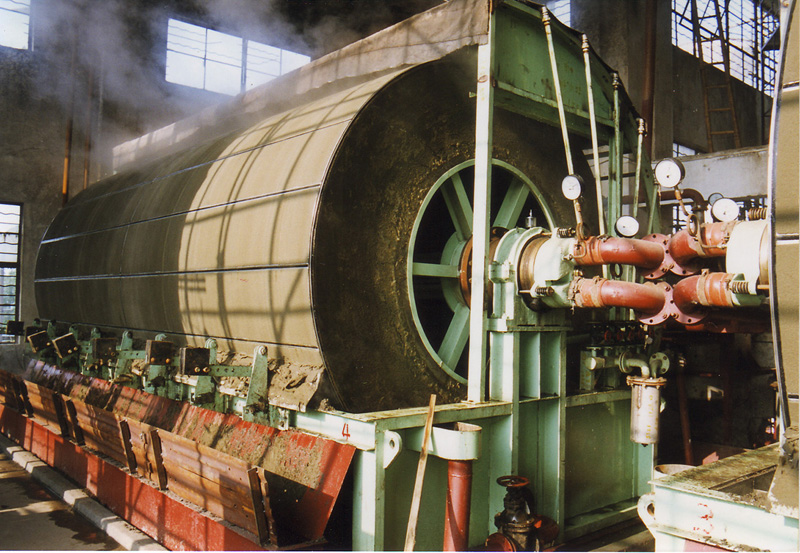

18.Vacuum suction filter without filter cloth

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

19.Rapid sedimentation device

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

20.Lime disinfection machine

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

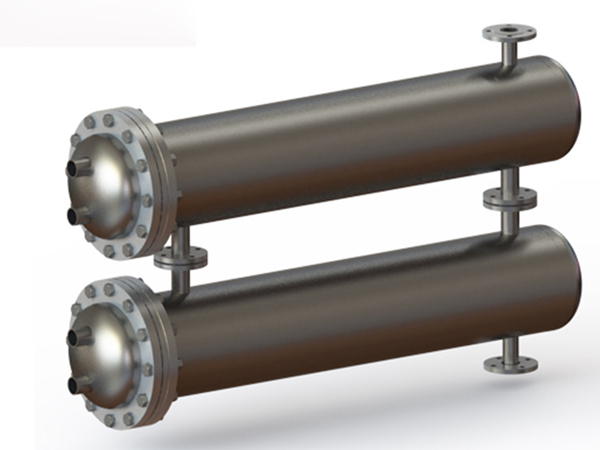

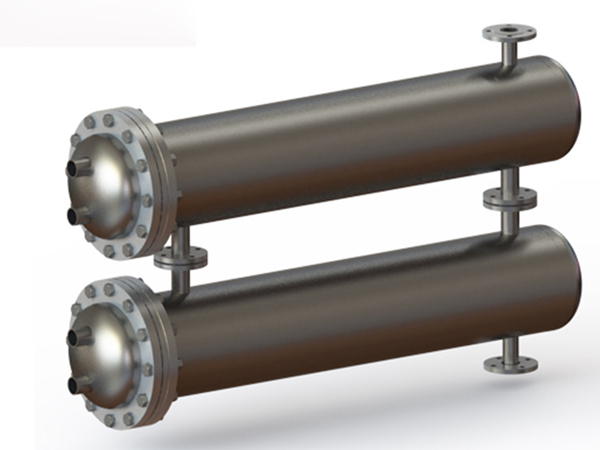

21.Heater

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

22.Drum sugarcane juice sieve

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

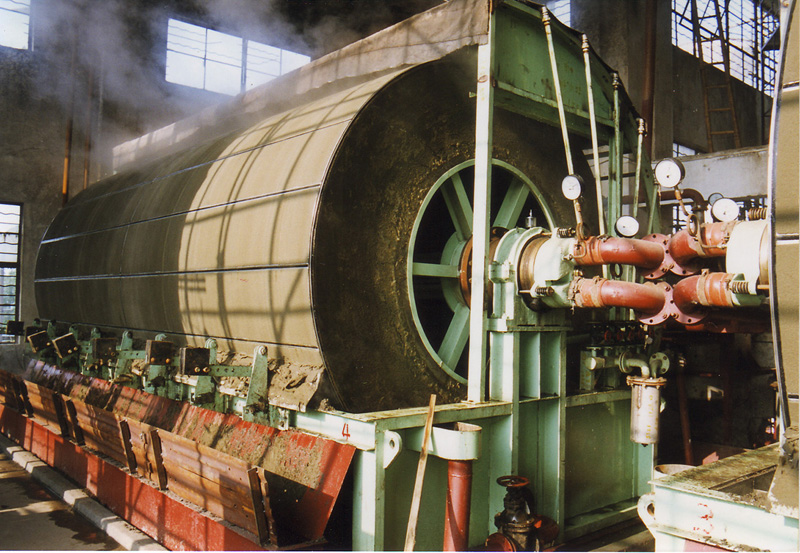

23.Press machine

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

24.Exudator

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

25.Sand removal roller

Processing capacity: 5- 1,000 tons

Application scope: Sugarcane

26.Heavy-duty pendulum sugarcane tearing machine

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

27.Sugarcane knife machine

Processing capacity: 500- 5,000tons

Application scope: Sugarcane

28.Conveyor sugarcane feeder

Processing capacity: 500- 5,000 tons

Application scope: Sugarcane

29.Single crystal machine

Processing capacity: 1-5

Application scope: Rock sugar

30.Vacuum condenser

Processing capacity: 100- 50,000

Application scope: Liquid

31.Customized stainless steel liquid storage tanks

Processing capacity: 100- 50,000

Application scope: Liquid

32.Boil the sugar pot

Processing capacity: 100- 50,000

Application scope: White sugar and sucrose

33.Seed machine

Processing capacity: 100- 50,000

Application scope: Rock sugar