Vertical mill

Vertical mill, also known as roller mill, is an ideal equipment for grinding industry that integrates crushing, drying, grinding, grading and conveying. Its high production efficiency, can be block, granular and powdered raw materials into the required powder materials; The fineness of the product can meet the industry standard for the preparation of pulverized coal.

Specifications and models: ZKRM88.2-ZKRM24.3

Capacity: 1~240t/h (detailed parameters see the following technical parameters table)

Applicable materials: Vertical roller mill mainly grinding raw materials, clinker, mineral powder, slag, granulated blast furnace slag, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, phyllite, clay, sand, bauxite, silica fume, etc.

Application industry: cement chemical industry, coal, electric power and other industries.

Vertical mill product introduction

Vertical mill is an ideal large grinding equipment, widely used in cement chemical industry, coal, electric power and other industries of large-scale material grinding and ultrafine grinding processing, is a crushing, drying, grinding, grading, conveying in one of the ideal grinding industry equipment.

Outstanding advantage

1, high grinding efficiency, low power consumption;

2, less metal consumption per unit product;

3, the process is simple, while completing the material grinding, drying, powder selection function;

4, small footprint, compact layout, light weight of system equipment, low civil construction investment.

Working principle

In the process of powder production, the main motor drives the mill plate to rotate through the reducer, while the hot air enters the vertical mill body from the air inlet, the material falls to the center of the mill through the feeding pipe, the constant speed rotating mill plate with the help of centrifugal force will evenly disperse and smooth the raw material outward, so that it forms a specific thickness of the material bed, and the material is rolled by several grinding rollers on the mill plate at the same time, and is crushed. Under the continuous drive of centrifugal force, the material continues to move to the outer edge of the disk. When the material leaving the disk encounters the hot gas entering the mill through the wind ring and rises accordingly, it enters the separator through the middle shell of the mill. In this process, the material and the hot gas carry out sufficient heat exchange, and the water is quickly evaporated. The separator controls the particle size of the finished product at the exit of the roller mill, the particles larger than the specified size are separated and fall back to the mill, and the materials that meet the fineness requirements enter the dust collector through the separator, and the collected finished products are sent to the finished product bin.

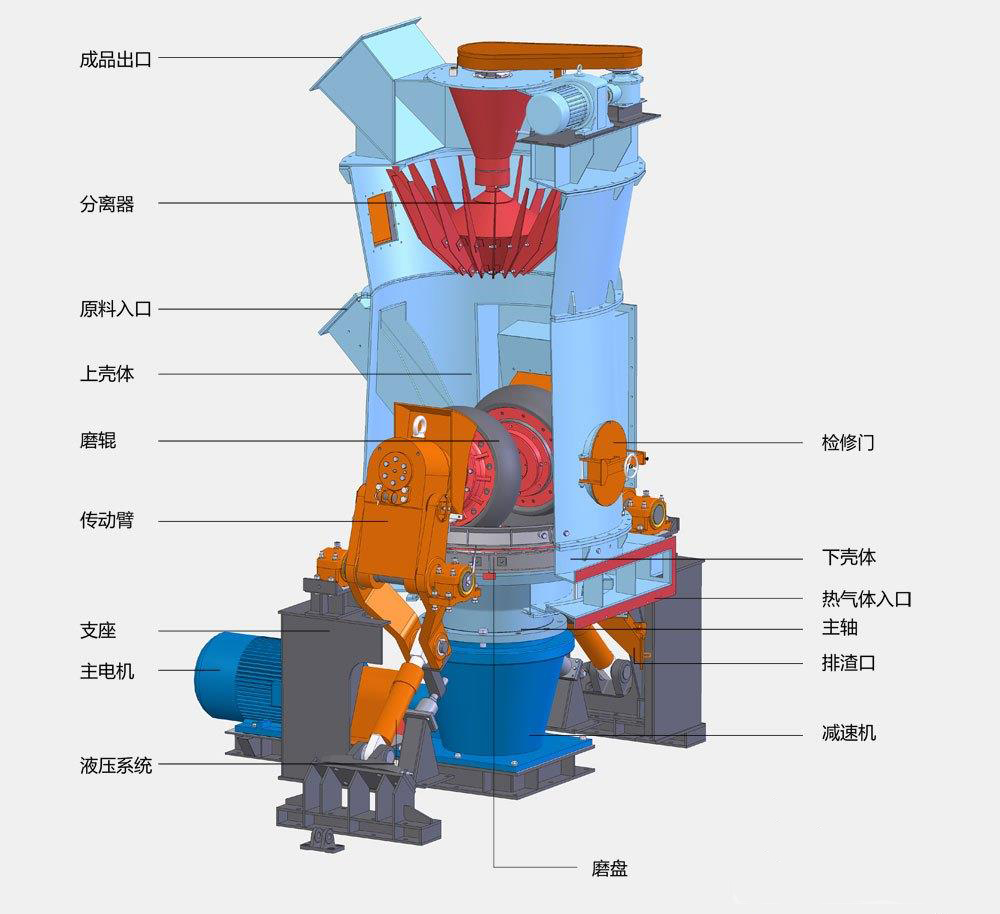

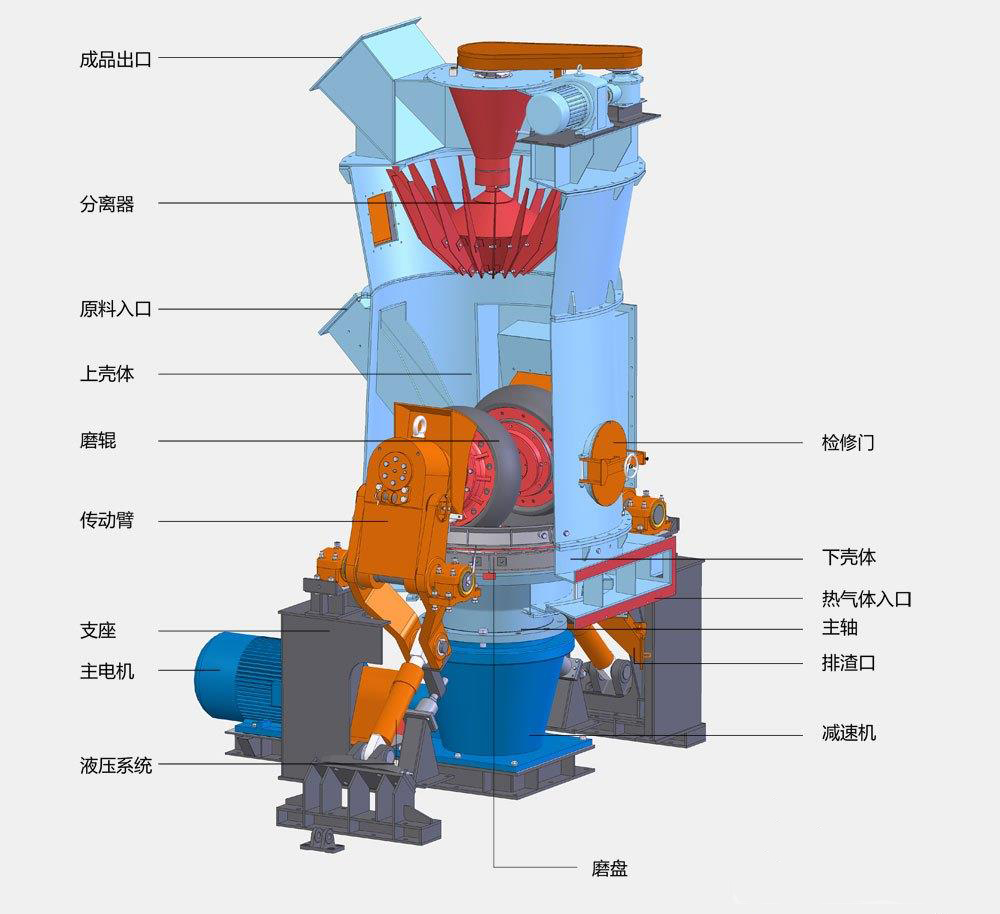

Structure composition:

The vertical mill consists of a grinding disc, a grinding roller, a powder separator, a pressure device, a monitoring device, a transmission device, a water spraying system, a coarse powder external circulation system and other structures.

1, grinding disc: including guide ring, wind ring, baffle ring, lining plate, disc body, scraper and lifting device.

2, grinding roller: roller sleeve is easy to wear parts, requiring enough toughness and good wear resistance.

3, powder separator, can be divided into static, dynamic and combined powder separator three categories

4, pressure device: hydraulic device, energy storage.

5, monitoring device: rocker arm monitoring, vibration monitoring.

6, transmission device: motor, reducer.

7. Water spraying system: reduce temperature and stabilize material layer.

8, coarse powder external circulation system: elevator.

Technical parameter

| Model number | Yield (t/h) | Disk geometry diameter (mm) | Disk track diameter (mm) | Raw material moisture (%) | Fineness of raw material (%) | Raw material moisture (%) | Main motor Power (kW) |

| ZKRM1300 | 20-25 | 1870 | 1300 | <10% | R0.08≤12% | ≤1% | 200 |

| ZKRM1500 | 26-34 | 2180 | 1500 | <10% | R0.08≤12% | ≤1% | 280 |

| ZKRM1700 | 40-50 | 2400 | 1700 | <10% | R0.08<12% | ≤1% | 400 |

| ZKRM1900 | 60-70 | 2680 | 1900 | <10% | R0.08<12% | ≤1% | 500 |

| ZKRM2200 | 85-110 | 2900 | 2200 | <10% | R0.08<14% | ≤1% | 800 |

| ZKRM2400 | 95-130 | 3140 | 2400 | <10% | R0.08<14% | ≤1% | 900 |

| ZKRM2800 | 120-160 | 3300 | 2800 | <10% | R0.08<14% | ≤1% | 1250 |

| ZKRM3400 | 190-240 | 4560 | 3400 | <10% | R0.08<15% | ≤1% | 1800 |

Note: Grindability of raw materials (bond)

Index ≤12kWh/t. |

| ZKRM pulverized coal vertical mill specifications, technical parameters table |

| Specification and model | Yield (t/h) | Disk geometry diameter (mm) | Disk track diameter (mm) | Feed size (mm) | Raw coal moisture (%) | Fineness of pulverized coal (%.R0.08) | Coal moisture content (%) | Main motor Power (kW) |

| ZKRM800M | 5-8 | 1100 | 800 | 25 | <10 | 5-12% | ≤1% | 110 |

| ZKRM1100M | 7-12 | 1520 | 1100 | 25 | <10 | 5-12% | ≤1% | 132 |

| ZKRM1300M | 10-15 | 1870 | 1300 | 25 | <10 | 5-12% | ≤1% | 185 |

| ZKRM1500M | 16-22 | 2180 | 1500 | 30 | <10 | 5-12% | ≤1% | 250 |

| ZKRM1700M | 20-28 | 2400 | 1700 | 30 | <10 | 5-12% | ≤1% | 315 |

| ZKRM1900M | 26-35 | 2680 | 1900 | 35 | <10 | 5-12% | ≤1% | 400 |

| ZKRM2200M | 40-45 | 2900 | 2200 | 40 | <10 | 5-12% | ≤1% | 500 |

| Note: Raw coal has a grinding coefficient of 50-90. |

| ZKRM slag vertical mill specifications, technical parameters table |

| Specification and model | Yield (t/h) | Annual output tons/year) | Disk geometry diameter (mm) | Disk track diameter (mm) | Feed size (mm) | Slag moisture (%) | Specific surface area (m2/kg) | Product moisture (%) | Main motor Power (kW) |

| ZKRM1500S | 6-8 | 5 | 2180 | 1500 | <50 | <12 | ≥420 | <1 | 280 |

| ZKRM1700S | 10-12 | 8 | 2400 | 1700 | <50 | <12 | ≥420 | <1 | 400 |

| ZKRM1900S | 15-18 | 10 | 2680 | 1900 | <50 | <12 | ≥420 | <1 | 500 |

| ZKRM2200S | 25-28 | 15 | 2900 | 2200 | <50 | <12 | ≥420 | <1 | 800 |

| ZKRM2400S | 35-40 | 20 | 3140 | 2400 | <50 | <12 | ≥420 | <1 | 1250 |

| ZKRM2800S | 45-50 | 30-35 | 3300 | 2800 | <50 | <12 | ≥420 | <1 | 1600 |

| ZKRM heavy calcium powder vertical mill specifications, technical parameters table |

| Specification and model | Yield (t/h) | Disk geometry diameter (mm) | Disk track diameter (mm) | Feed size (mm) | Water content of grinding material (%) | Fineness of product | Product moisture (%) | Main motor Power (kW) |

| ZKRM1100L | 6-9 | 1520 | 1100 | 20 | <5 | 325mesh

(44μm)

90% pass | ≤1% | 132 |

| ZKRM1300L | 12-13 | 1870 | 1300 | 25 | <5 | ≤1% | 200 |

| ZKRM1500L | 14-20 | 2180 | 1500 | 35 | <5 | ≤1% | 280 |

| ZKRM1700L | 18-25 | 2400 | 1700 | 35 | <5 | ≤1% | 355 |

| ZKRM1900L | 25-30 | 2680 | 1900 | 40 | <5 | ≤1% | 450 |

| ZKRM2200L | 30-40 | 2900 | 2200 | 40 | <5 | ≤1% | 560 |

| ZKRM2400L | 40-50 | 3140 | 2400 | 40 | <5 | ≤1% | 710 |

| ZKRM2800L | 50-55 | 3300 | 2800 | 45 | <5 | ≤1% | 900 |